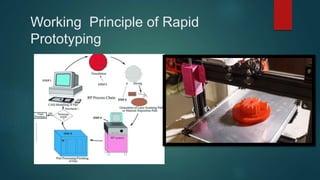

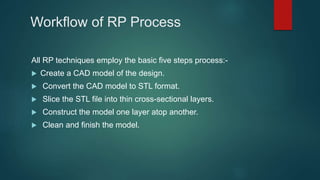

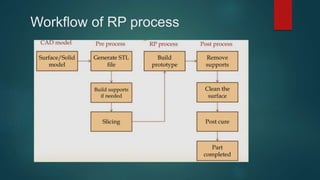

Rapid prototyping allows engineers to create physical models using 3D CAD data and layer-by-layer construction. The process involves designing a part in CAD software, converting it to an STL file, slicing the digital model into layers, and building a physical prototype one layer at a time. Rapid prototyping reduces costs and development time by finding design issues earlier compared to traditional prototyping methods.