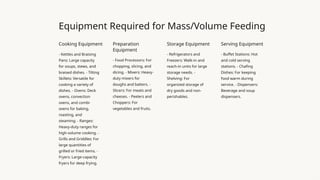

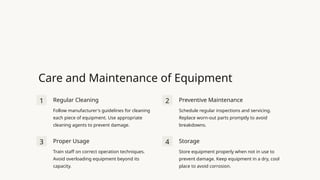

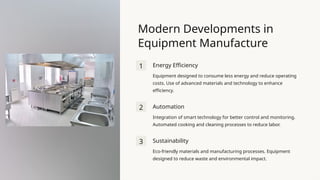

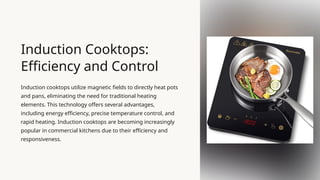

This presentation outlines essential equipment and technology for large-scale food production in commercial kitchens, covering cooking, preparation, storage, and serving equipment. It emphasizes the importance of regular cleaning, preventive maintenance, and modern advancements such as energy efficiency, automation, and sustainable practices. Key innovations include high-tech ovens, sous-vide cooking, induction cooktops, and smart refrigeration systems, which significantly enhance efficiency and food quality.