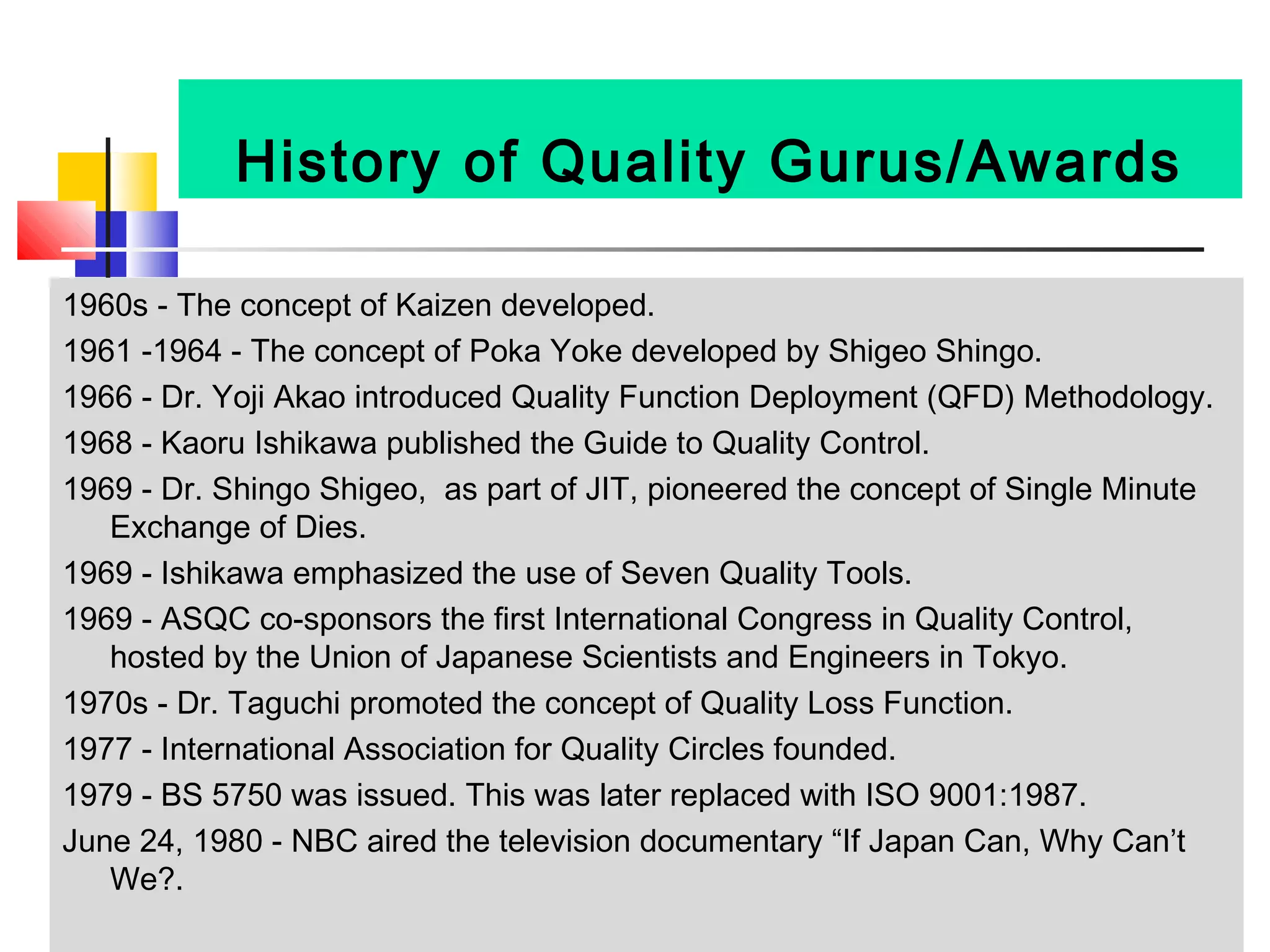

The document provides a history of quality gurus and awards from 1901 to 2015. It summarizes key events and contributions including: Sir John Wolfe-Barry establishing standardization of iron and steel sections in 1901; Frederick W. Taylor publishing "The Principles of Scientific Management" in 1911; the formation of the American Society for Quality Control in 1946; Dr. Edward Deming helping Japanese industries after World War II in 1947; the establishment of the Deming Prize in 1951; and the introduction of Six Sigma at Motorola in 1986. It also profiles Malcolm Baldrige and William Edwards Deming, and outlines Deming's System of Profound Knowledge and his famous 14 Principles.