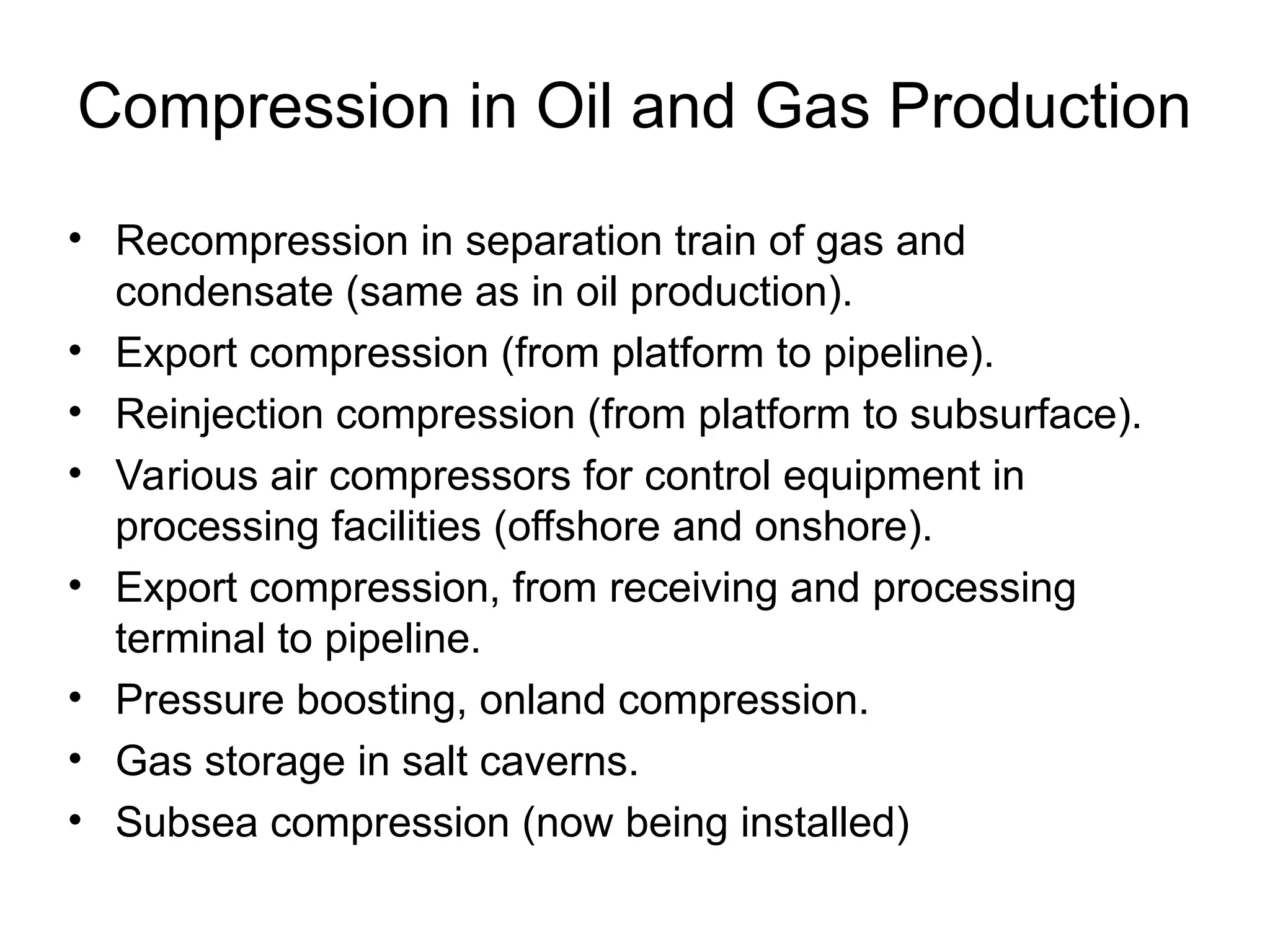

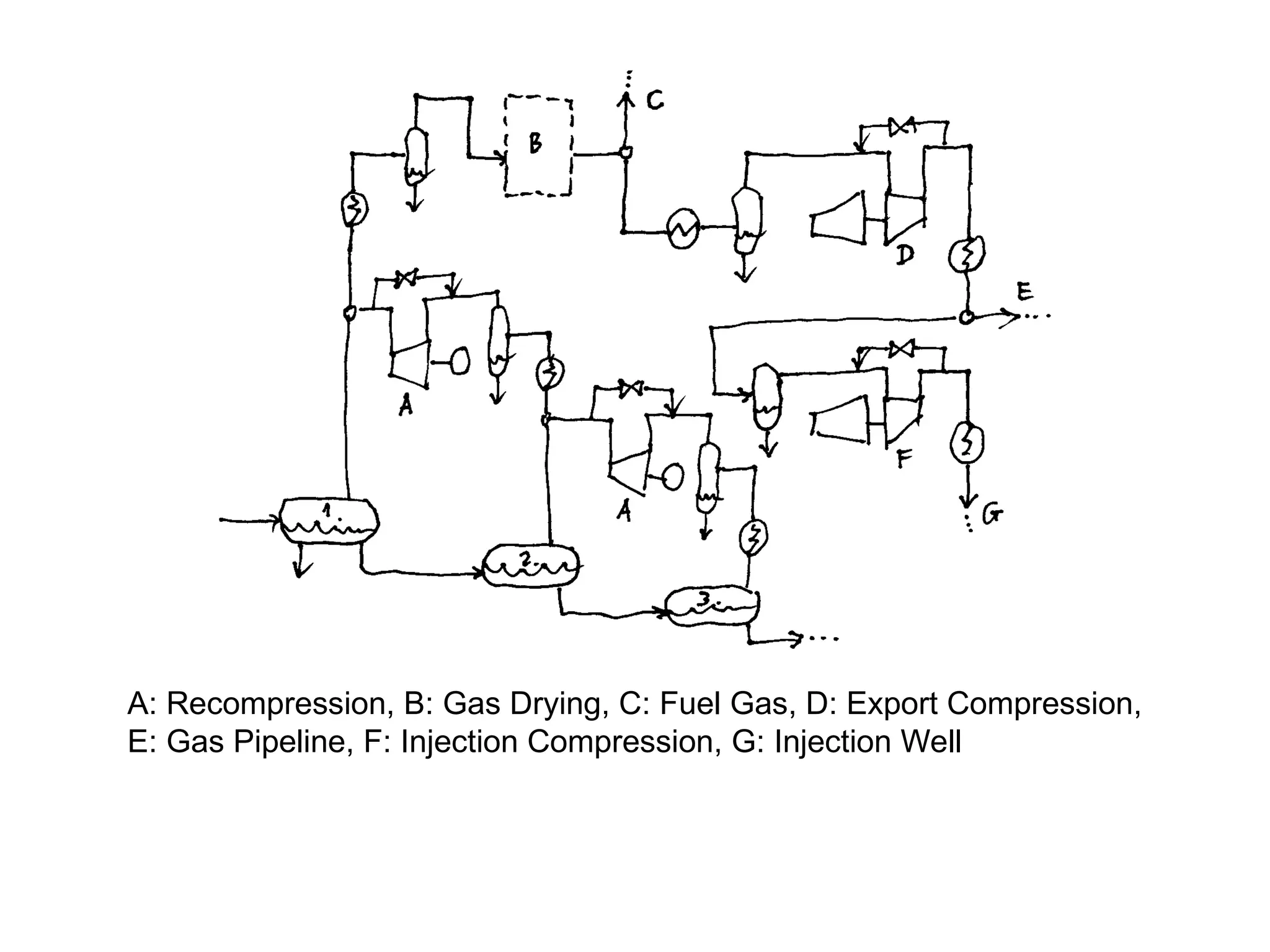

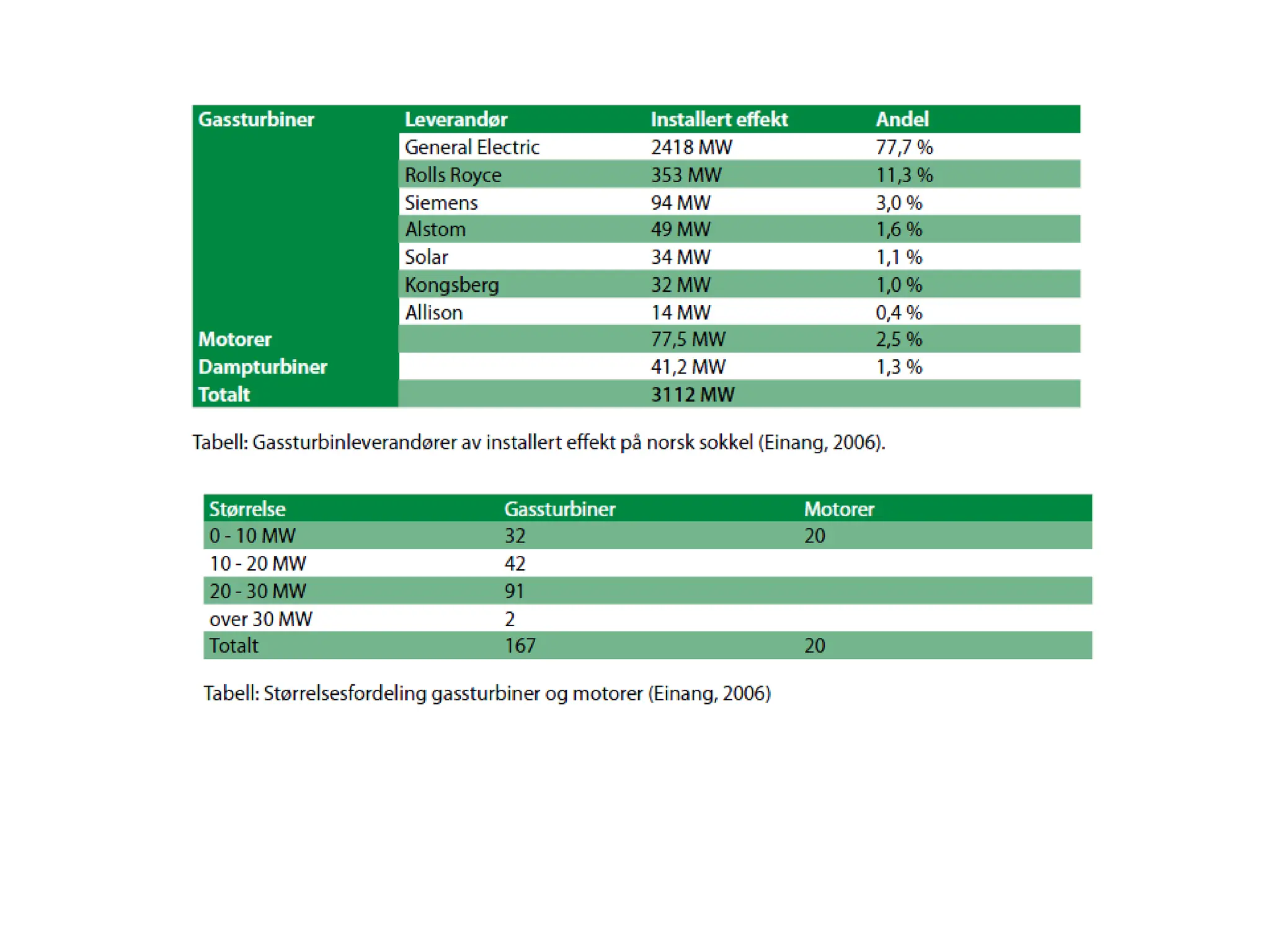

The document discusses various aspects of compression in the oil and gas industry, including types of compressors, their applications in offshore compression, and the efficiency of gas turbines. It highlights the significance of compression in different processes such as gas separation, export, and reinjection. Additionally, the text presents thermodynamic principles related to compressors and power calculations for efficient operation.

![Adiabatic/Isentropic Compression

2

1

vdp

W

1

1

1

1

2

1

1

k

k

p

p

k

k

v

p

W

1

1

1

1

2

1

k

k

p

p

k

k

RT

M

m

P

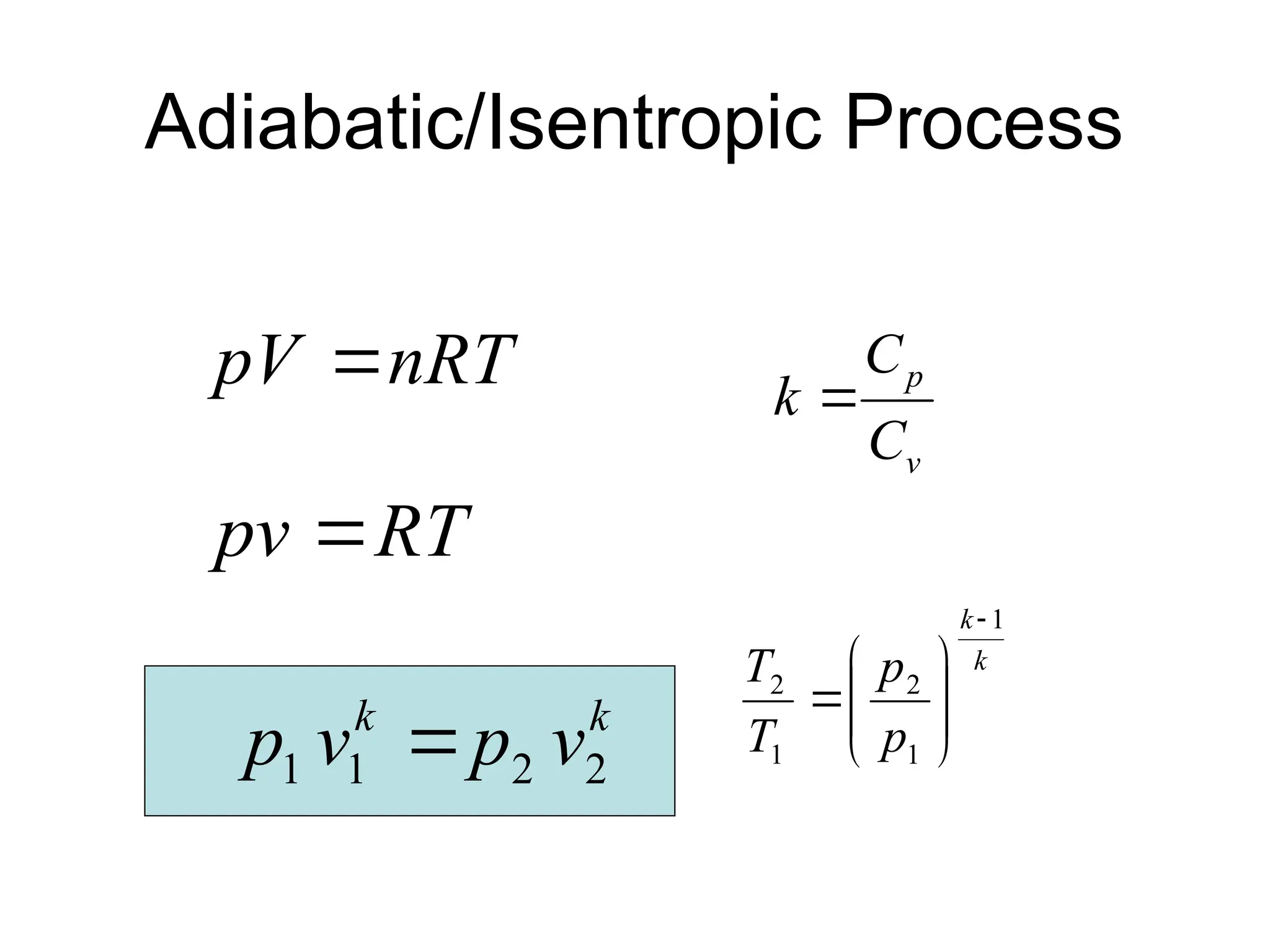

v [m3/mol], p [Pa=N/m2], W [Nm/mol=J/mol] = Specific work

pv=RT, Wm/M [J/mol kg/s mol/kg=J/s=W] = Power

nRT

pV

RT

pv ](https://image.slidesharecdn.com/13780981-240921152042-32a48ff1/75/process-of-petroleum-compression-1-ppt-17-2048.jpg)

![Summary

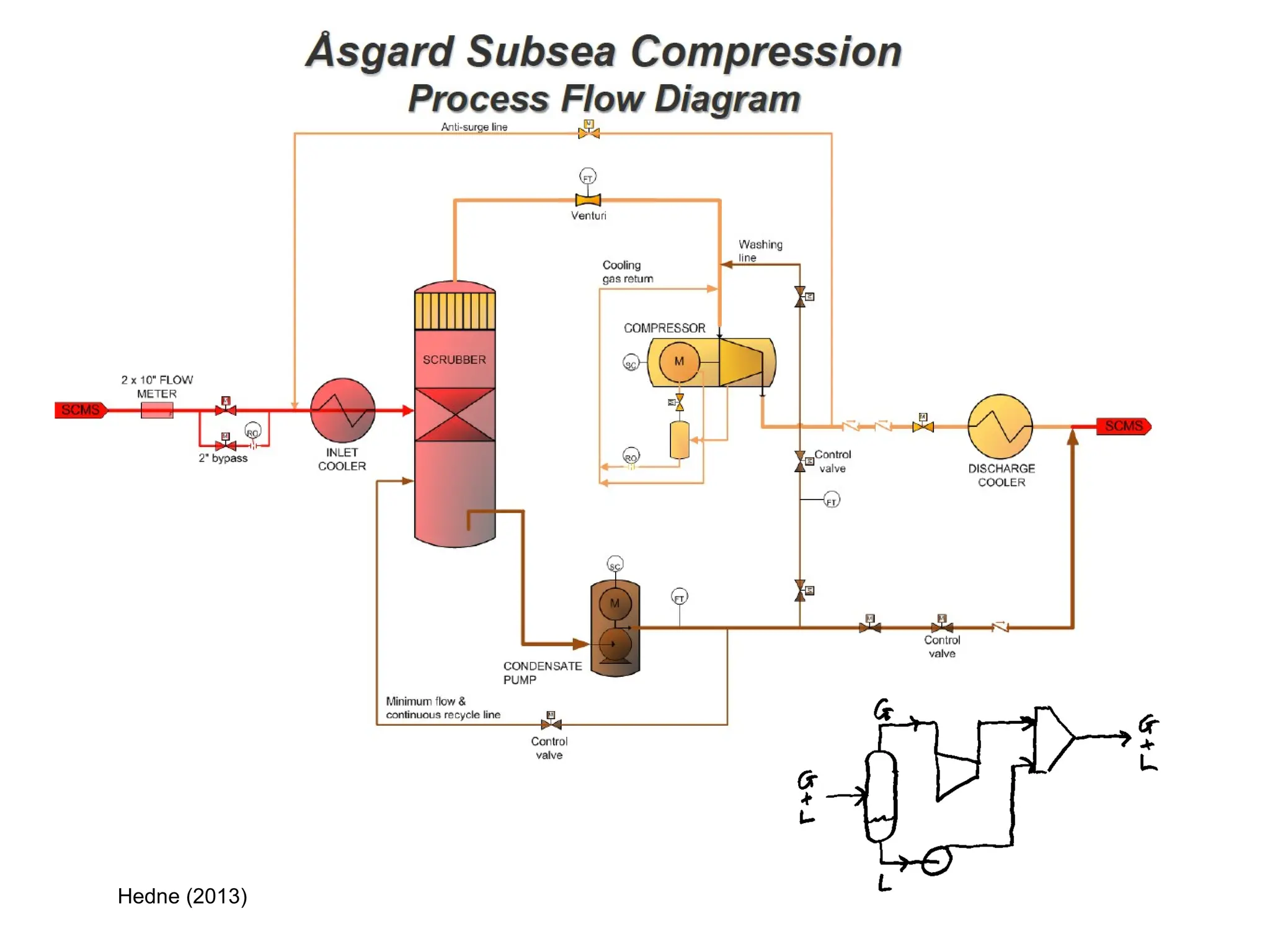

– Compression in oil and gas industry

– Offshore compression/compressors

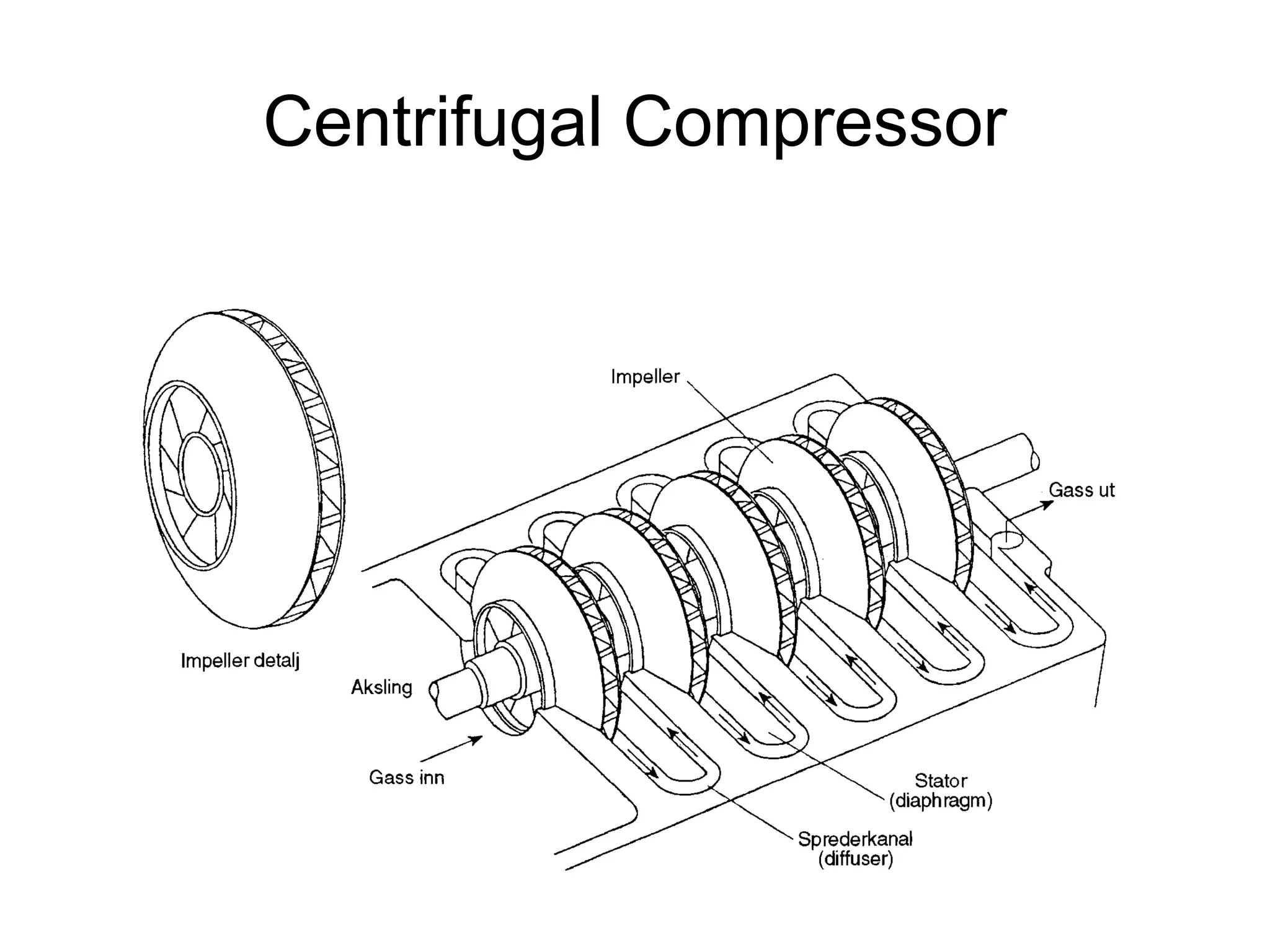

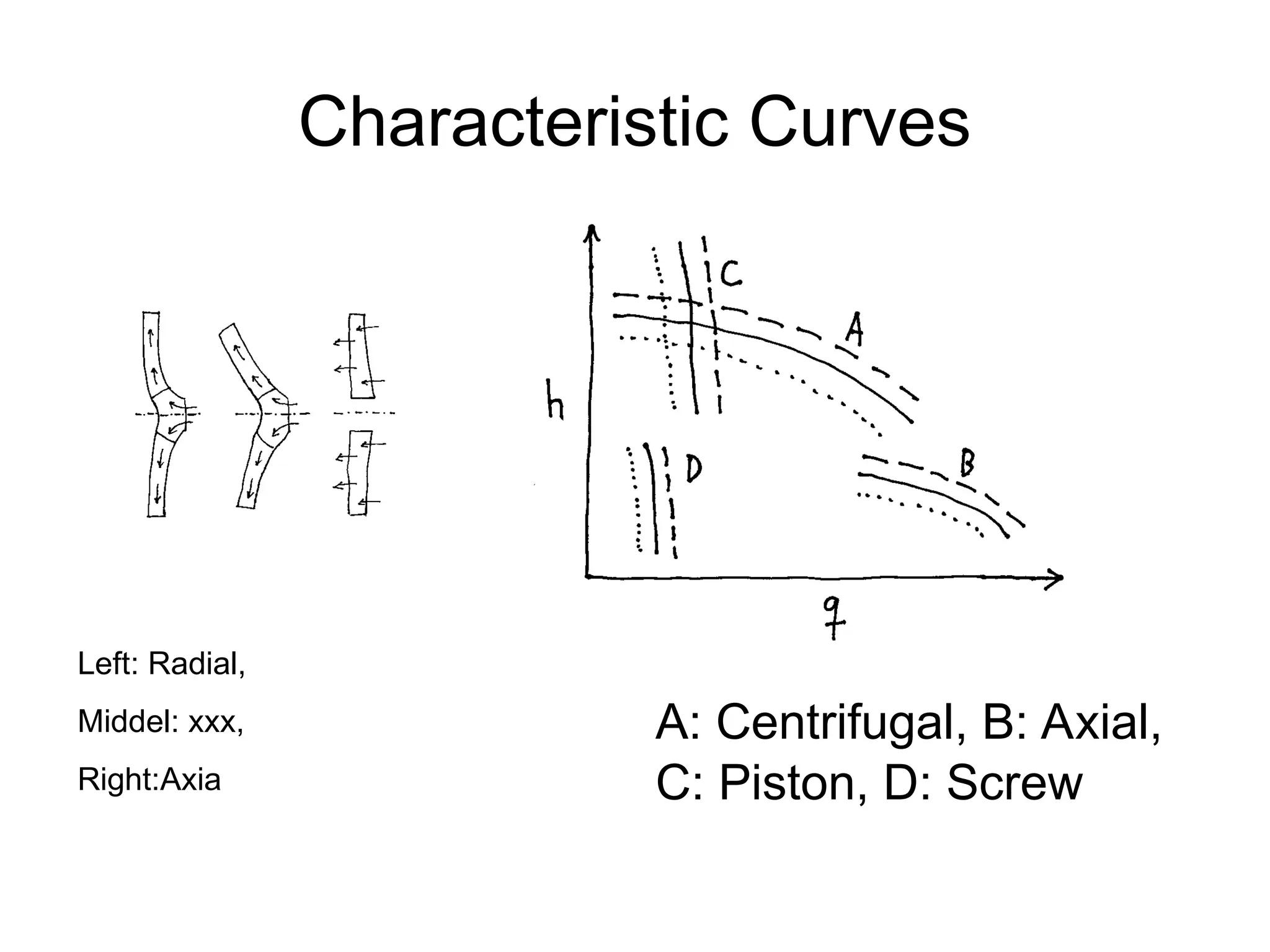

– Types of compressors

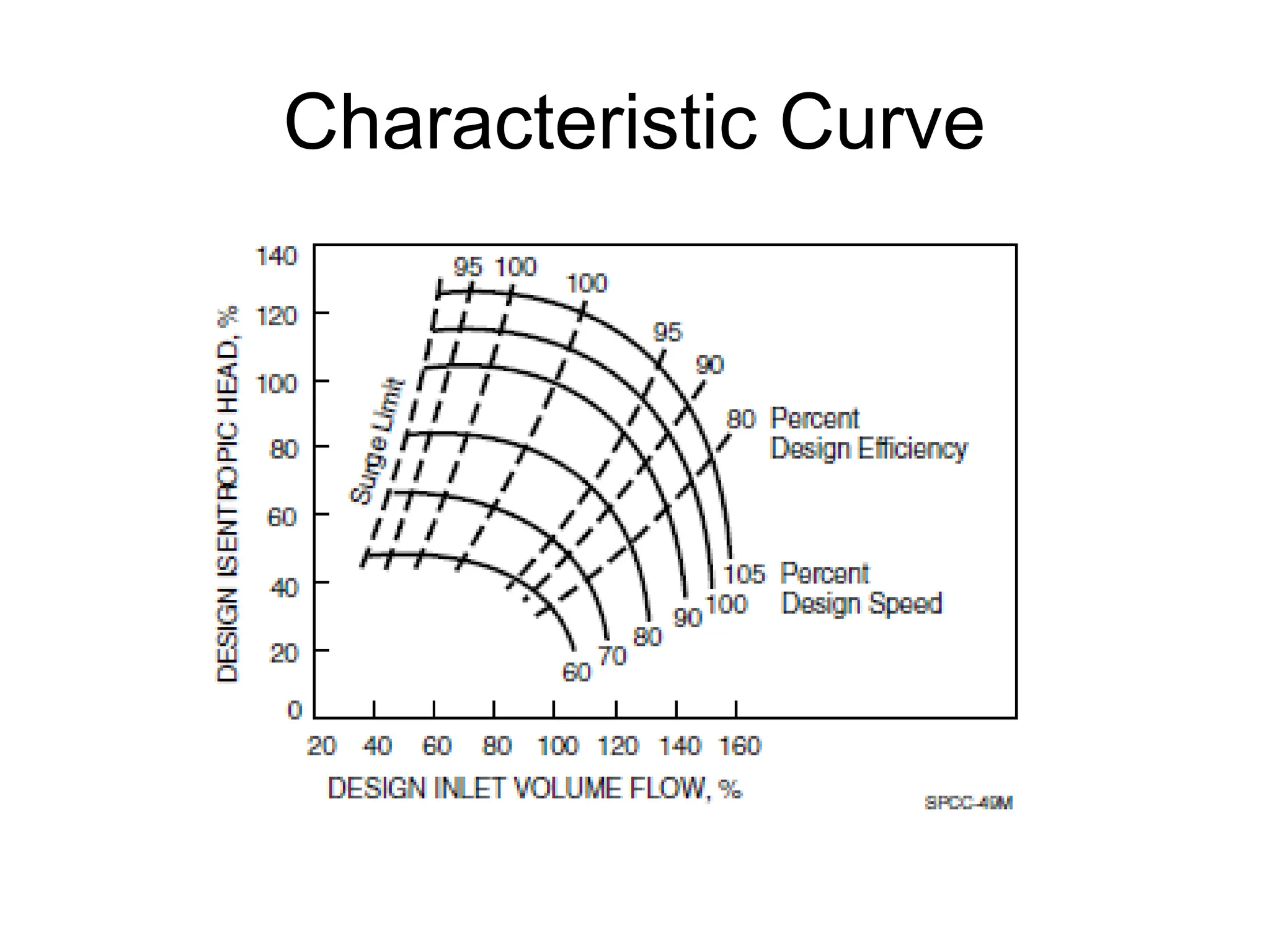

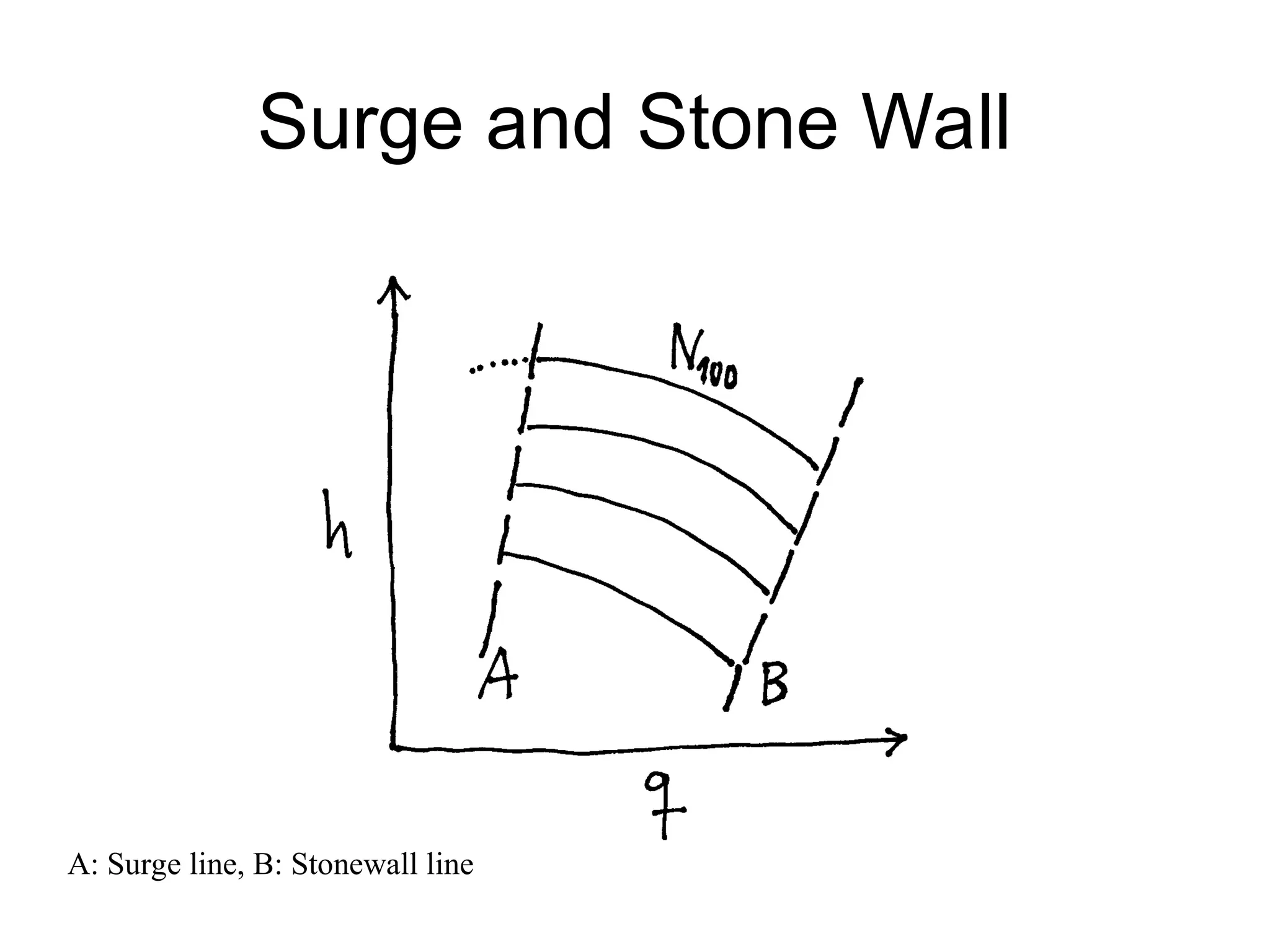

– Characteristic curves P [W] or h [J/kg] vs. q [m3/h]

– Calculation of compression power (isentropic)

– Surge and surge control

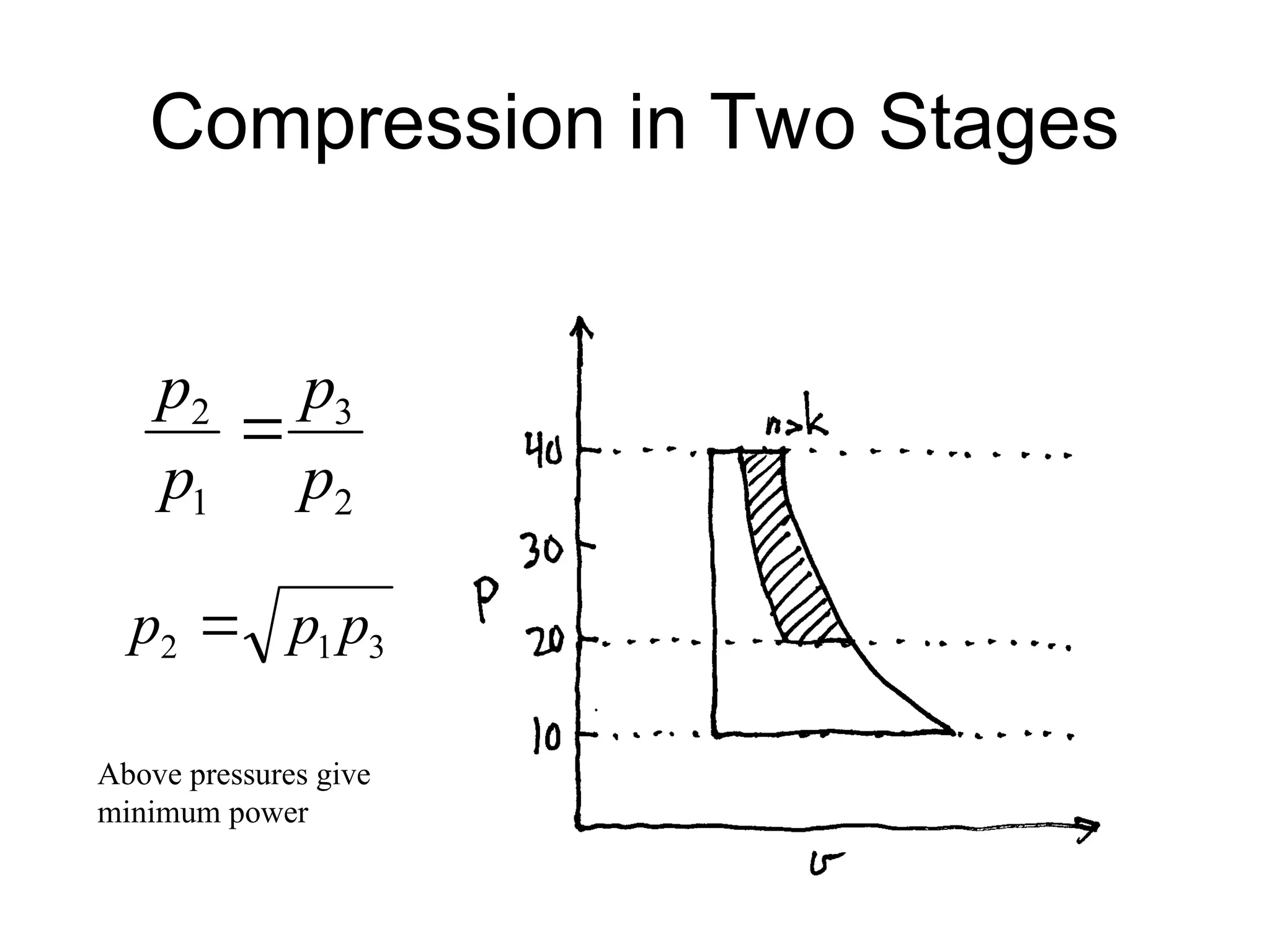

– Compression in stages with intercooling (minimum

power when equal power)

– Subsea compression](https://image.slidesharecdn.com/13780981-240921152042-32a48ff1/75/process-of-petroleum-compression-1-ppt-24-2048.jpg)