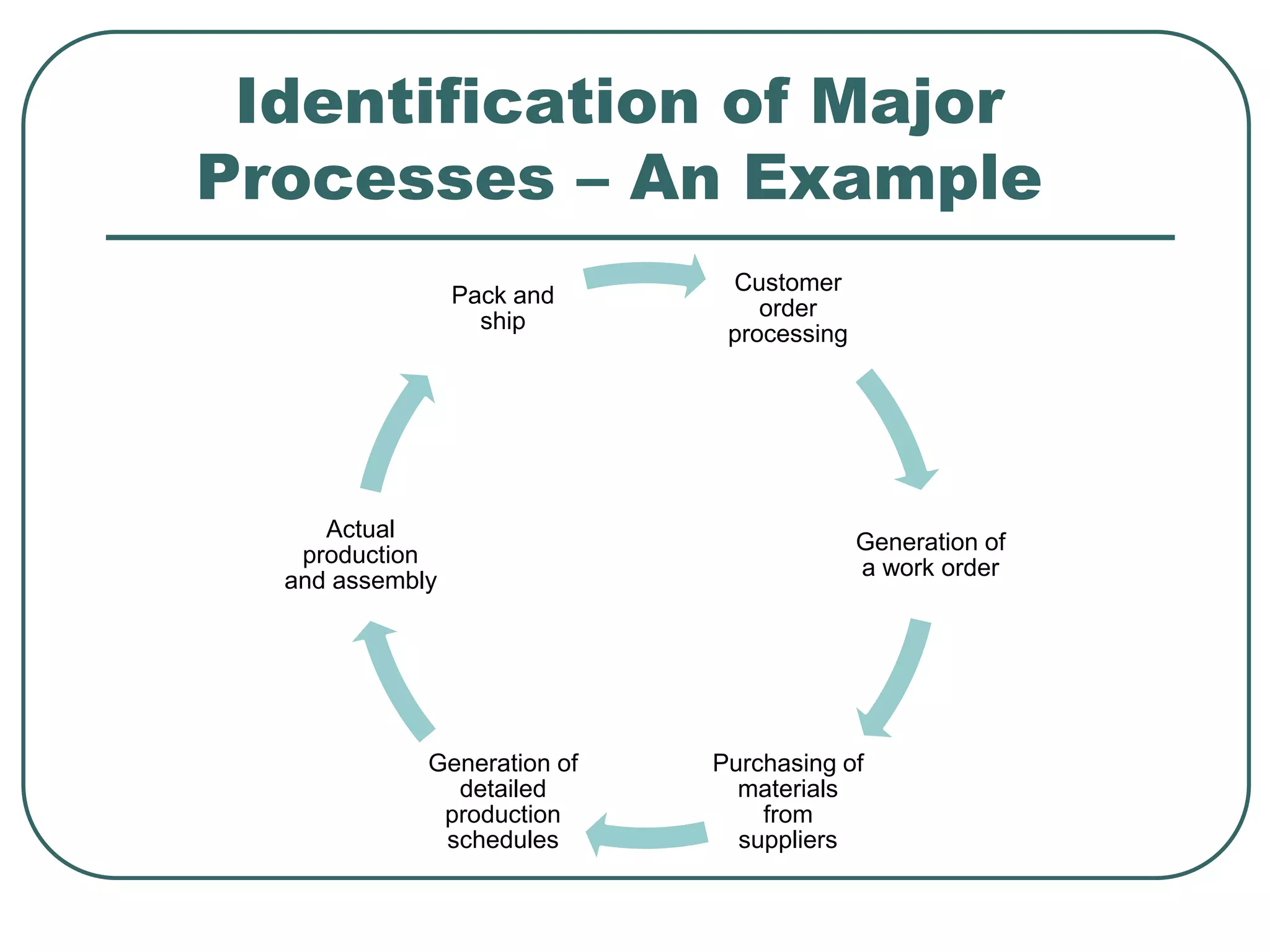

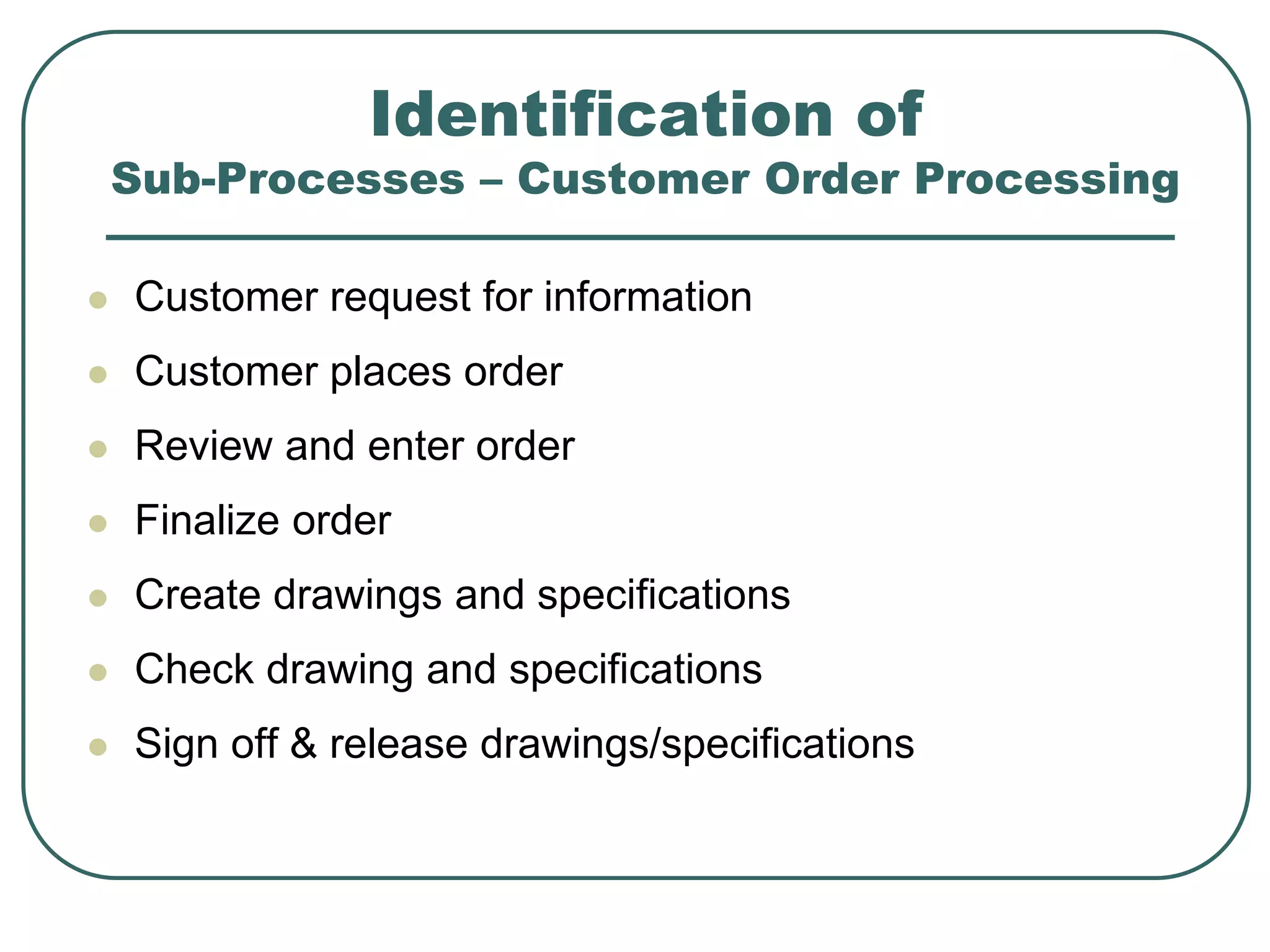

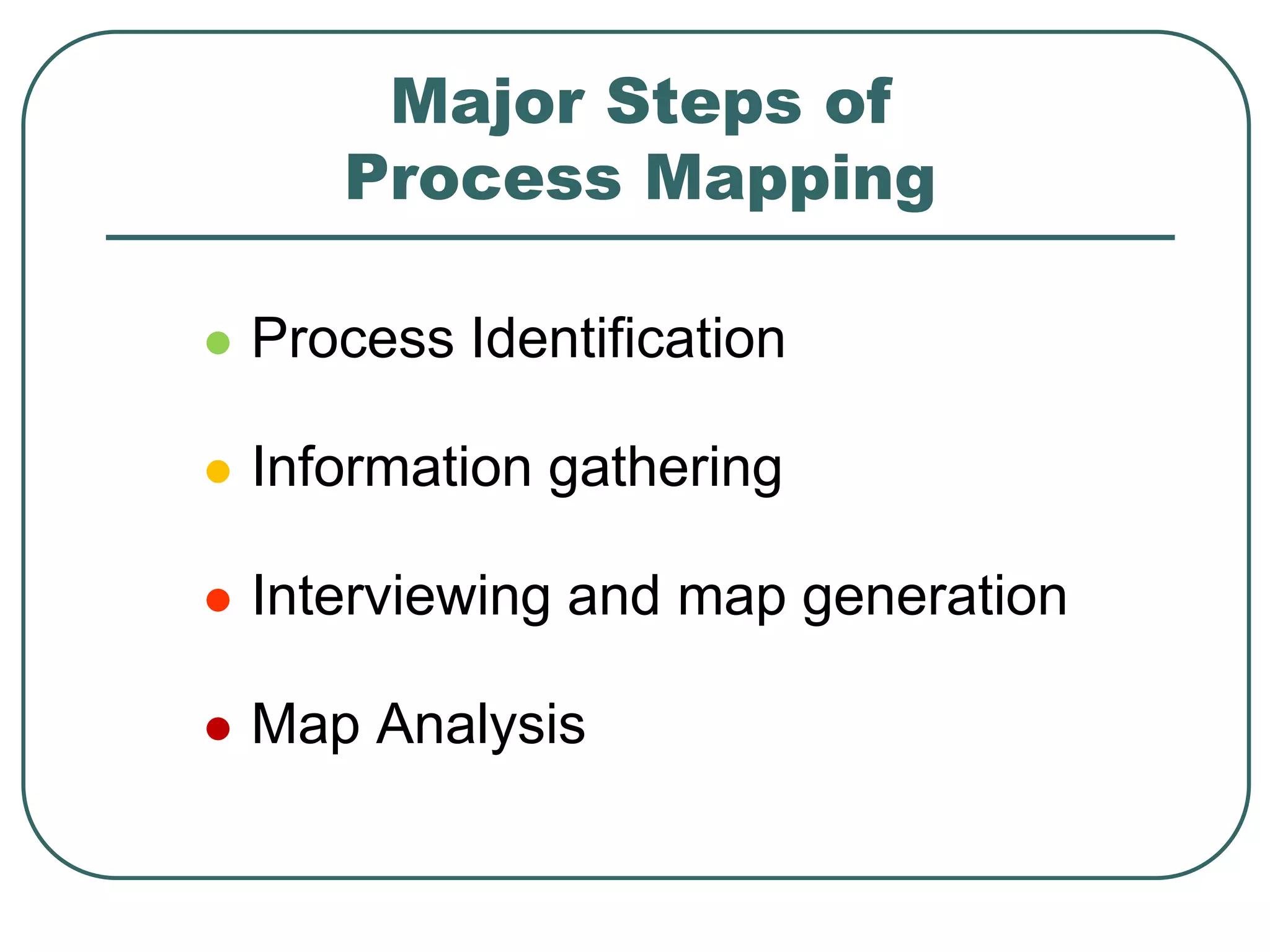

Process mapping is a method to graphically describe the steps that make up a process. It involves documenting, analyzing, controlling, improving, and redesigning processes. The major steps of process mapping are process identification, information gathering, interviewing, and map generation and analysis. Process mapping provides benefits like understanding processes visually, taking a holistic view, developing employee buy-in and pride, and creating customer-focused processes. Potential pitfalls include mapping without a clear purpose, getting lost in details, and not focusing on customers' needs.