Preventive maintenance is essential for ensuring the reliability, safety, and performance of material handling equipment (MHE) such as forklifts, conveyors, cranes, hoists, and pallet trucks. This SlideShare, “Preventive Maintenance for Material Handling Equipment — Complete Guide,” provides a practical, step-by-step framework for maintenance teams, plant managers, and reliability engineers to implement structured preventive maintenance that minimizes downtime, reduces repair costs, and enhances operational efficiency.

The presentation begins by defining what material handling equipment (MHE) includes and why it is critical to material flow, operational continuity, and workplace safety in warehouses, factories, and distribution centers. MHE assets are heavily used and often operate under demanding conditions; without systematic preventive maintenance, equipment failures can lead to production delays and safety incidents.

You’ll learn why preventive maintenance matters for MHE and how it prevents unexpected breakdowns, extends asset life, and protects capital investments. Preventive maintenance reduces workplace accidents, lowers emergency repair costs, and improves uptime and material flow efficiency. The deck outlines common risks that arise when maintenance is neglected, including high repair costs, increased safety violations, and production disruptions.

A key part of this guide highlights core preventive maintenance activities for material handling equipment. These include routine inspections of brakes, hydraulics, chains, belts, and wheels; proper lubrication of moving parts; regular battery and electrical system checks; and verification of safety devices. Structured scheduling — daily, weekly, monthly, and annual tasks — ensures that no critical inspection or task is missed.

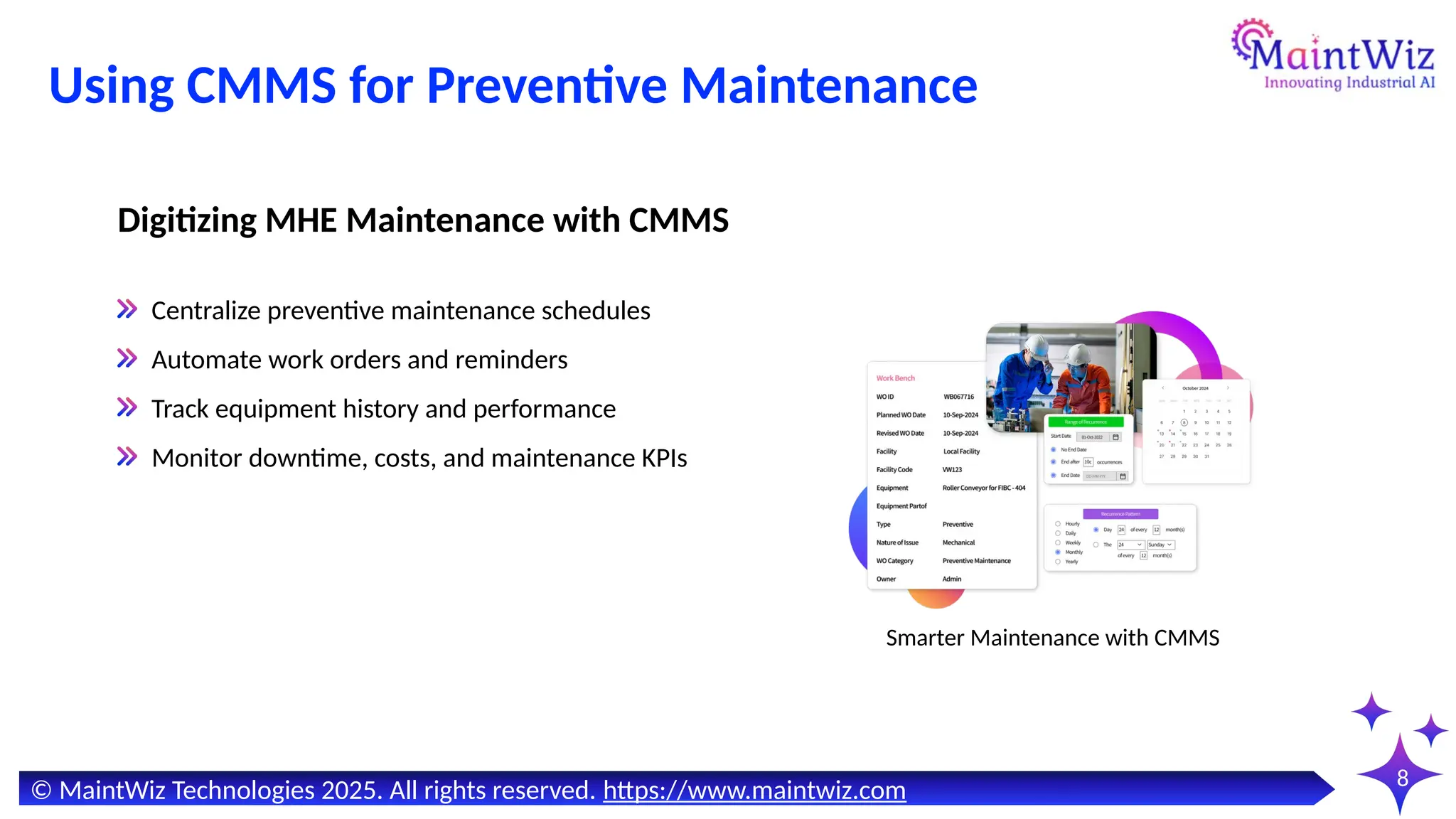

The SlideShare also explains how digital tools like CMMS (Computerized Maintenance Management System) enhance preventive maintenance practices. A CMMS centralizes schedules, automates reminders, tracks maintenance history, and provides real-time visibility into asset status. Mobile CMMS access enables technicians to receive work orders, record findings, and close tasks from the field, eliminating paperwork and improving response time.

The presentation emphasizes the importance of safety and compliance, showing how preventive maintenance aligns with workplace safety regulations, supports audit readiness, and fosters a prevention-first culture. It also outlines how performance metrics such as reduced downtime, improved MTBF (Mean Time Between Failures), and lower maintenance costs can be achieved through disciplined preventive maintenance.

Whether you manage a single facility or multiple sites, this SlideShare equips you with actionable preventive maintenance strategies, best practices, and tools needed to improve reliability, reduce operational risk, and boost overall plant performance using preventive maintenance for material handling equipment.