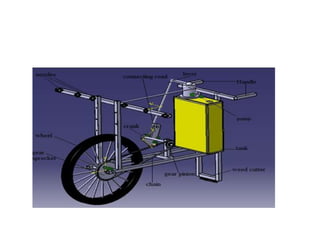

This document provides details of a final year project report for an agricultural wheel sprayer. It includes an abstract, introduction, construction details, working principle, advantages and disadvantages. The project aims to develop a reciprocating multi-sprayer that is mechanically operated using a slider crank mechanism to reduce the time and effort of spraying pesticides on crops as compared to traditional backpack sprayers. It also includes a weed cutter and allows for adjusting the spray pressure and nozzle placement. The working involves converting the rotary motion of the wheel into reciprocating motion using chain and sprocket transmission to a crankshaft driving the pump.