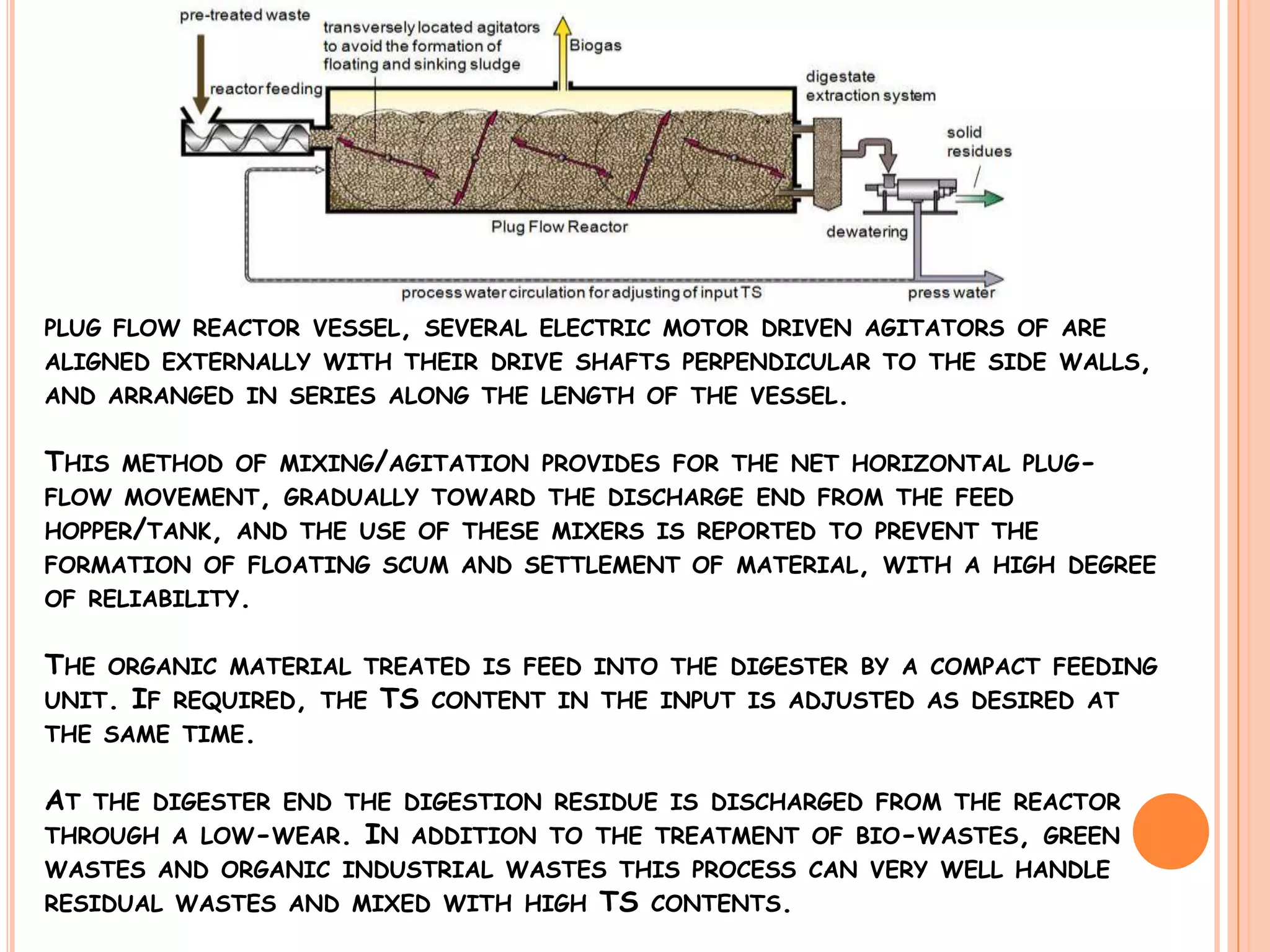

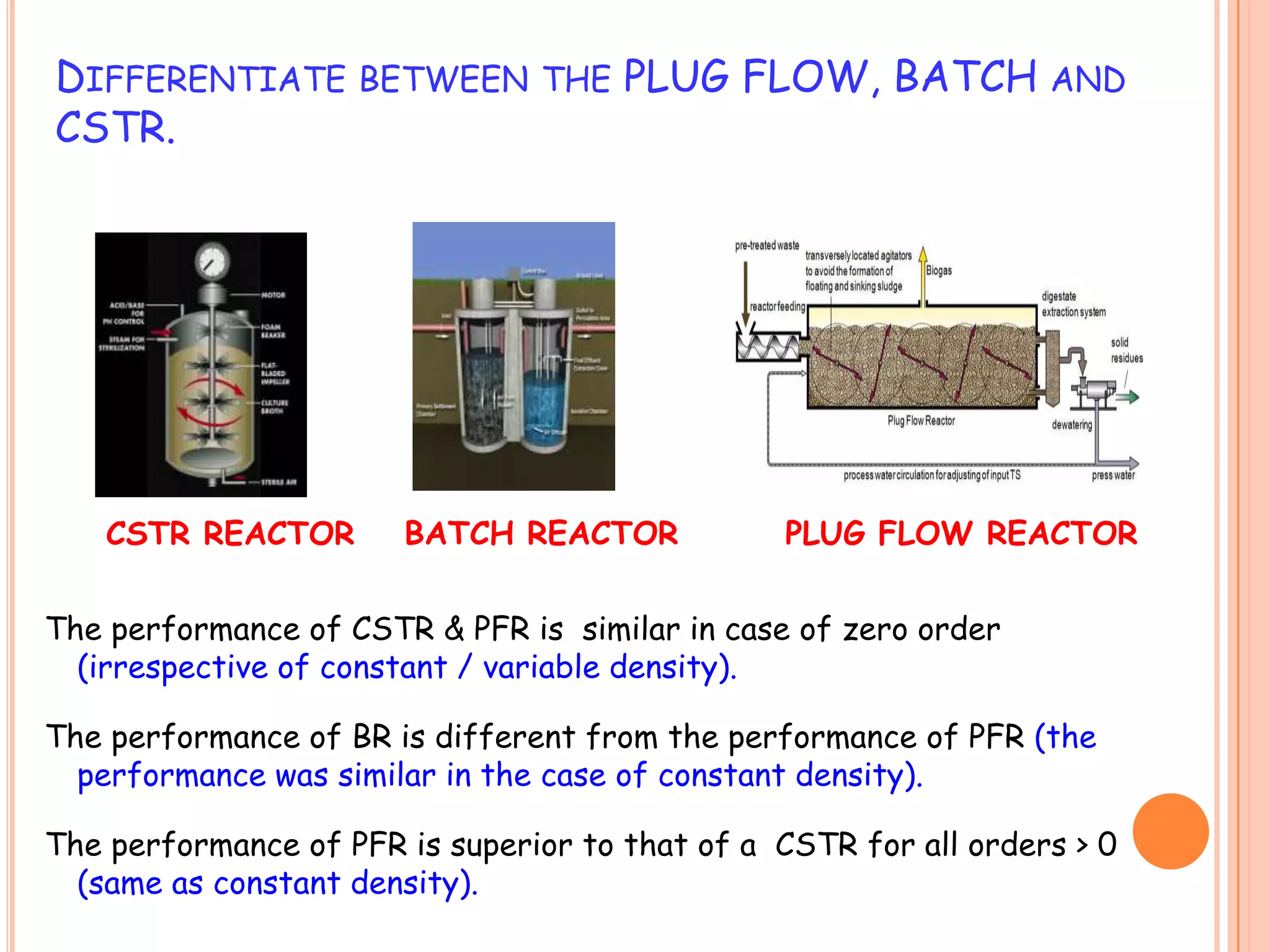

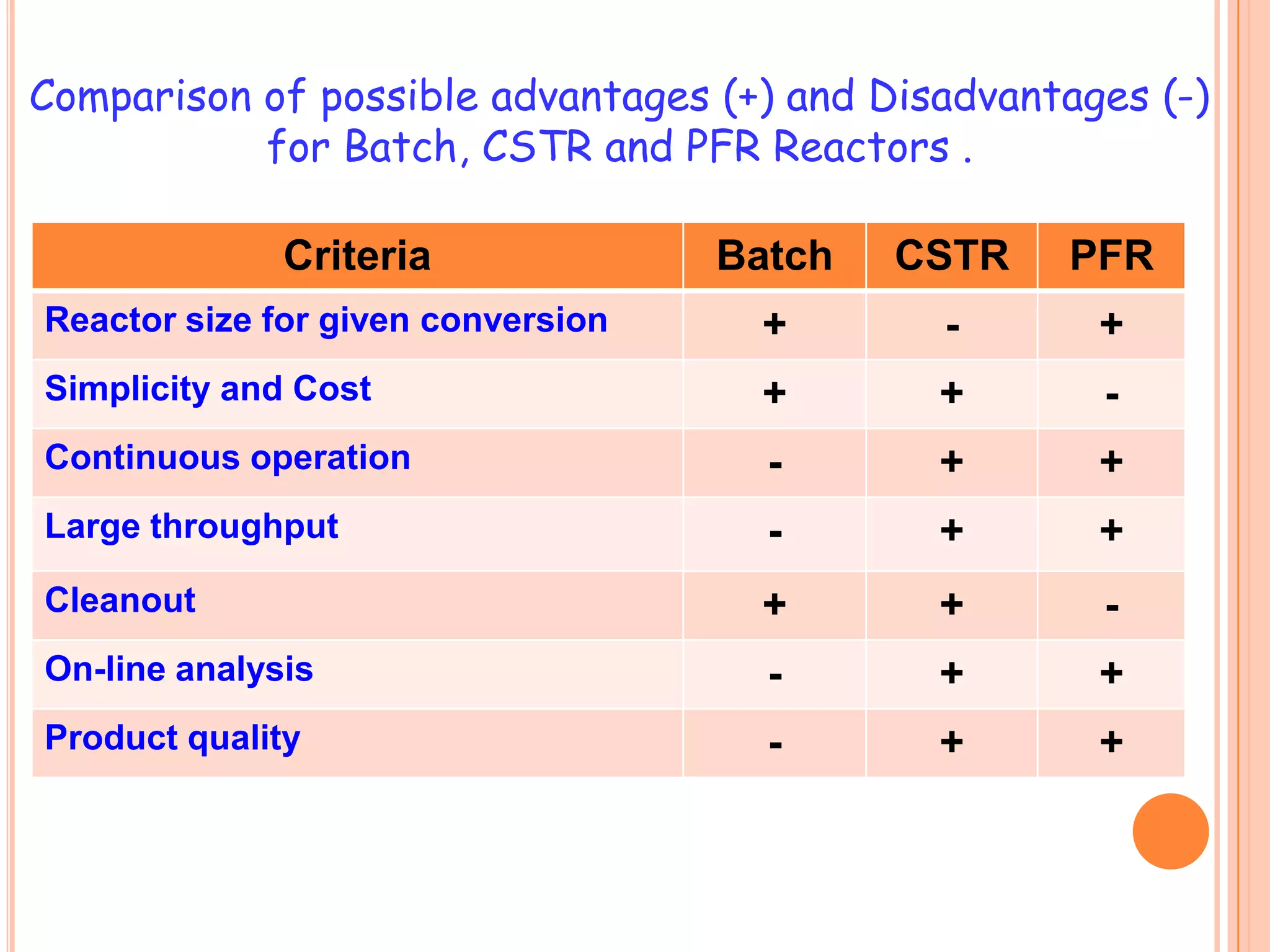

This document describes a plug flow reactor (PFR). A PFR is a model used to describe continuous chemical reactions in cylindrical systems where the residence time is the same for all fluid elements. It discusses how PFRs work with agitators along the vessel length to provide horizontal plug flow movement from feed to discharge. Advantages of PFRs include no moving parts, high conversion, and consistent product quality. Disadvantages can include poor temperature control and potential hot spots in exothermic reactions. The document compares the characteristics and performance of PFRs, continuous stirred-tank reactors (CSTRs), and batch reactors.