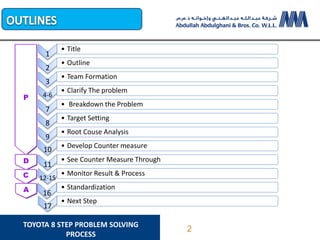

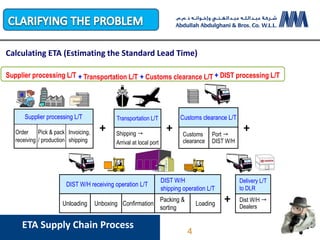

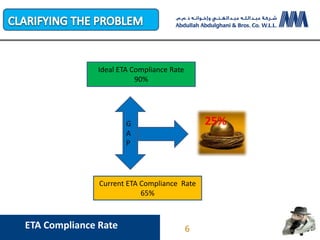

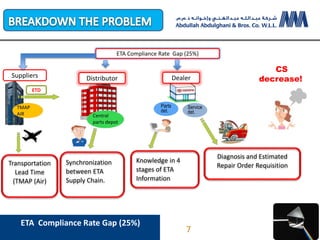

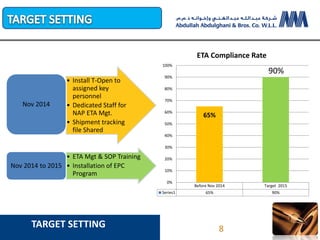

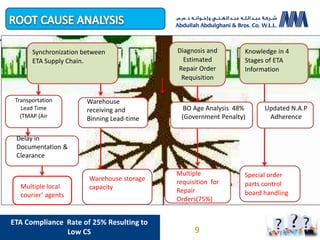

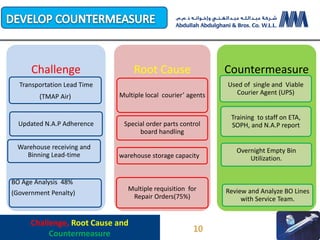

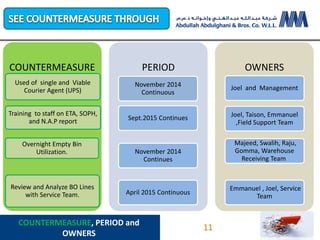

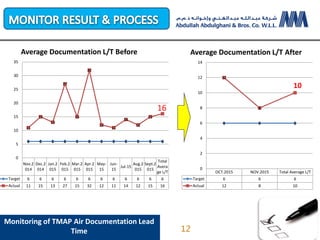

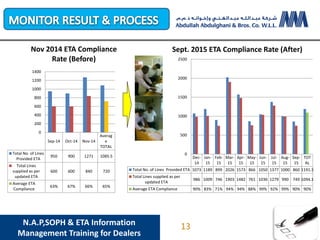

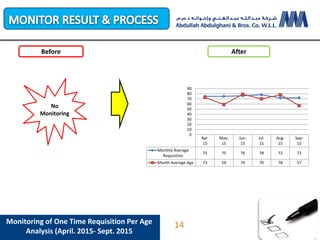

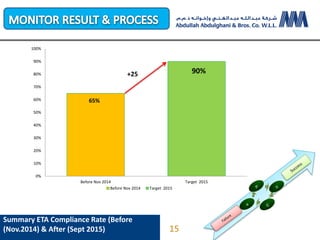

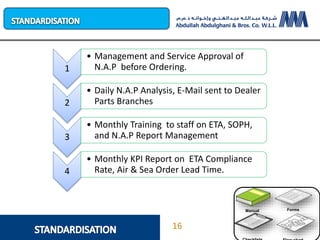

The document summarizes the parts kaizen marathon held in 2015 to improve the estimated time of arrival (ETA) compliance rate for parts distributions. The team analyzed the current 65% ETA compliance rate and set a target of 90% for 2015. Through root cause analysis, they identified issues like multiple couriers and lack of ETA knowledge. Countermeasures like using a single courier, empty bin utilization and training improved the compliance rate to 90% by September 2015. Monitoring showed reduced requisition aging. The team standardized manual forms and set a 98% target for 2016 to sustain the gains.