This document discusses and compares traditional procurement and management contracting procurement methods for a proposed 20-story condominium project in Kuala Lumpur.

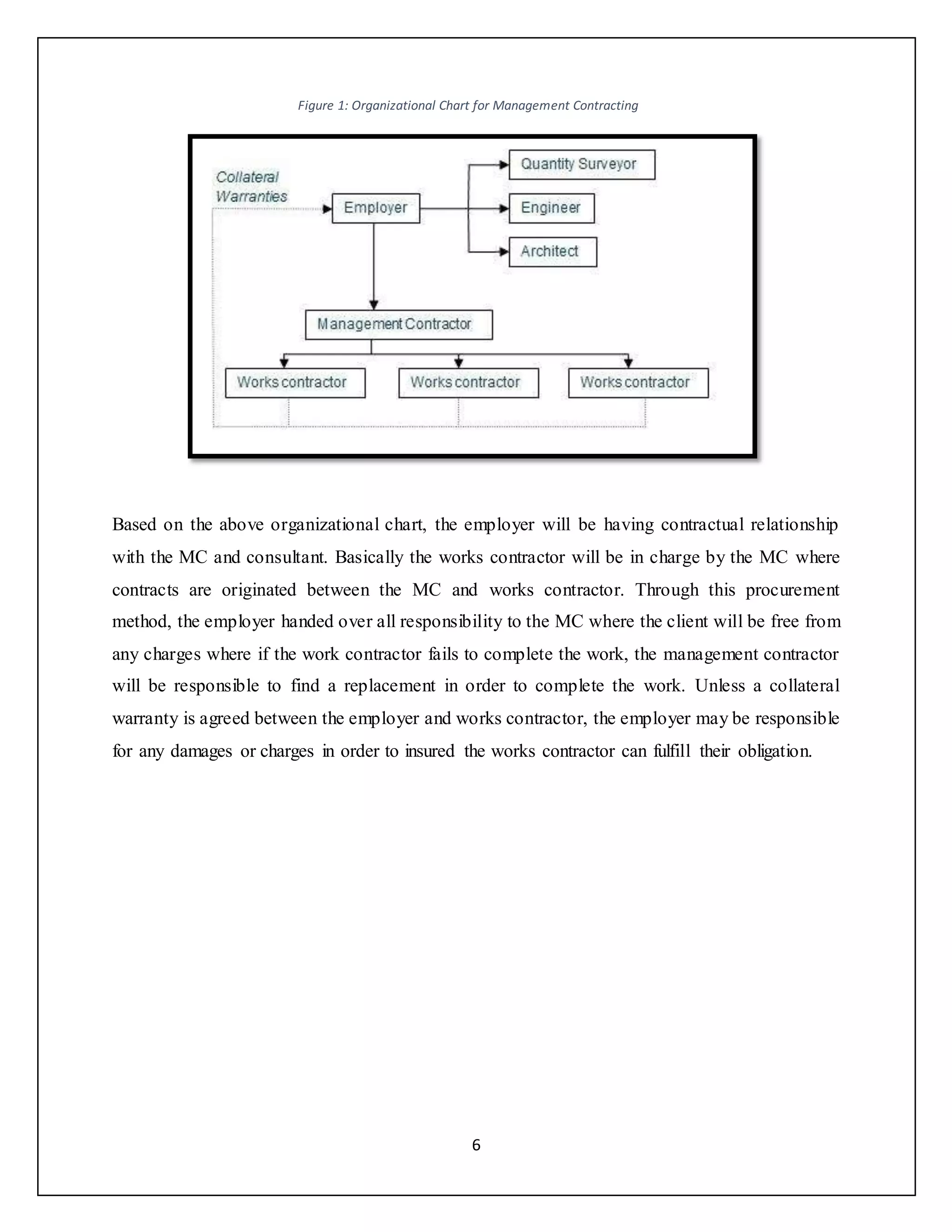

Management contracting is recommended as it allows for overlapping of design and construction phases, providing flexibility to make changes without compromising on cost control. It also allows selecting specialized subcontractors to help ensure project quality. In contrast, traditional procurement has a fixed contract sum set before construction and is less flexible for design changes.

Key factors in the recommendation include the client's priorities for on-time completion and quality, as management contracting can deliver the project faster while maintaining oversight of quality through specialist subcontractors. The overlapping phases also provide more control over sustainable design updates that may