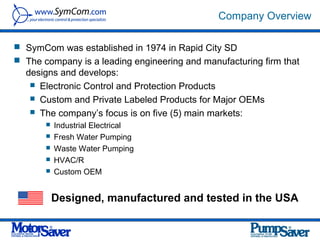

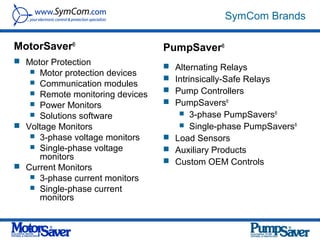

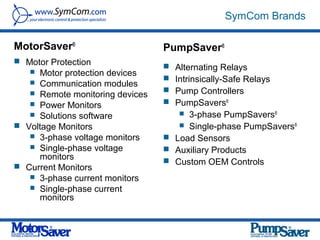

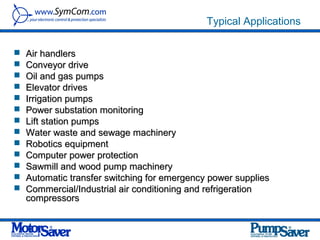

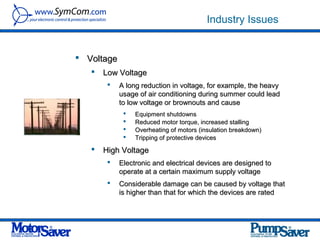

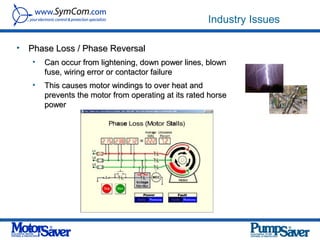

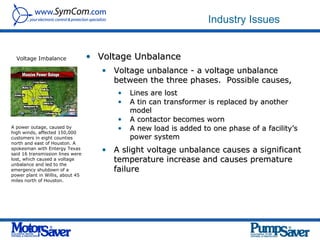

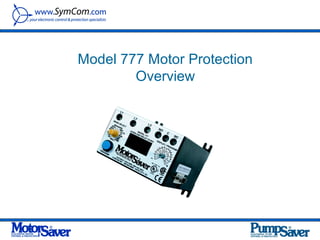

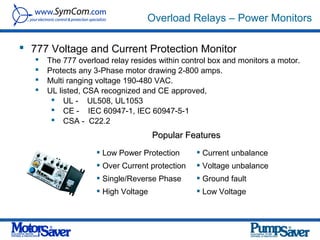

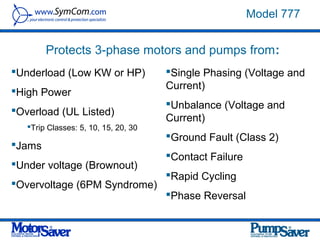

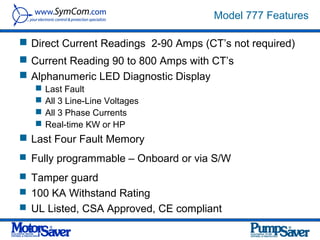

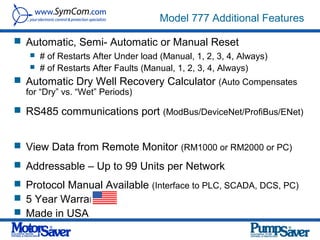

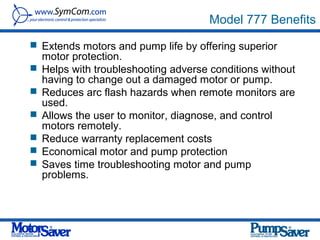

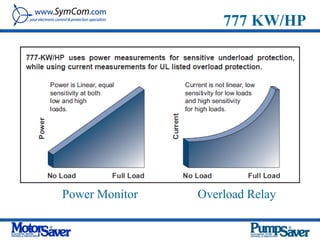

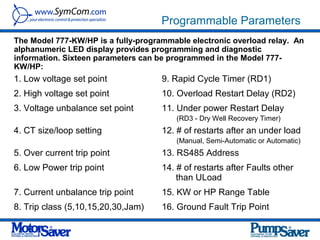

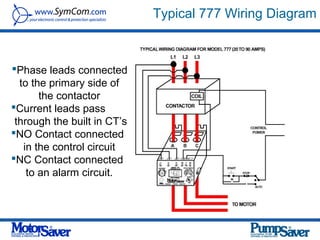

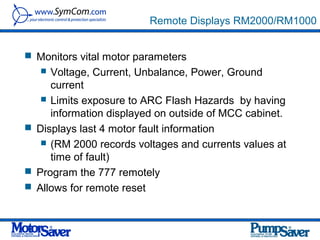

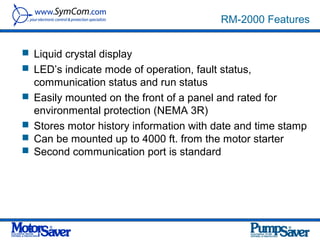

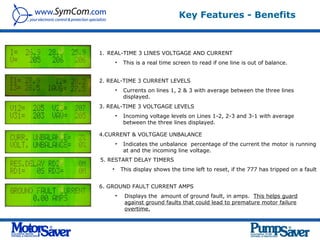

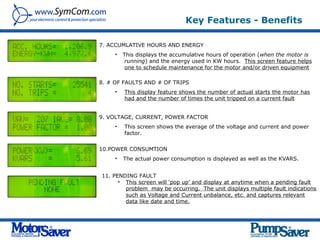

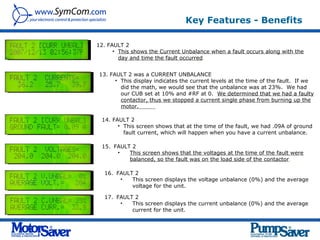

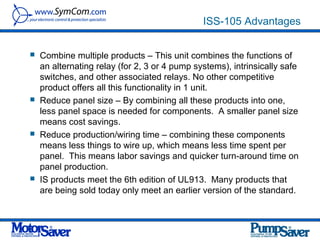

The document provides an overview of SymCom products, including their MotorSaver and PumpSaver brands. SymCom designs electronic control and protection products for industrial electrical systems, fresh water pumping, waste water pumping, HVAC/R, and custom OEM applications. Their flagship Model 777 product is a motor protection device that monitors voltage, current, and other parameters to protect motors and pumps from issues like overload, underload, single phasing, unbalance, and more.