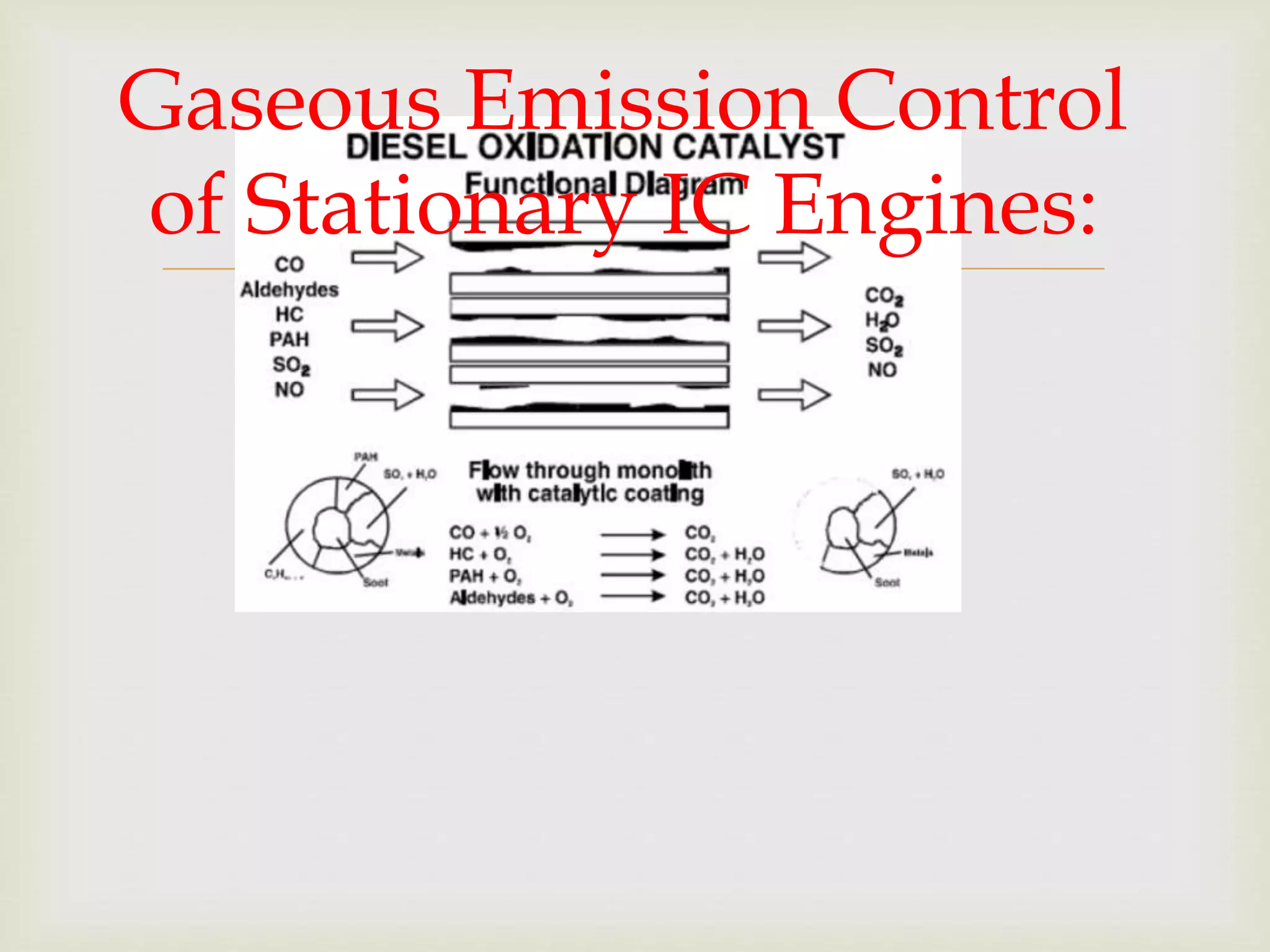

The document is a seminar report submitted for a master's degree in mechanical engineering. It discusses air pollution from internal combustion engines and methods to control emissions. It covers topics like types of pollutants from gasoline and diesel engines, their harmful effects, measurement techniques, and solutions like improving engine design, using cleaner fuels, and installing post-combustion control devices.

Where “i” is the total mass flow

into engine

EGR systems are made to operate mostly in the part-load

range-

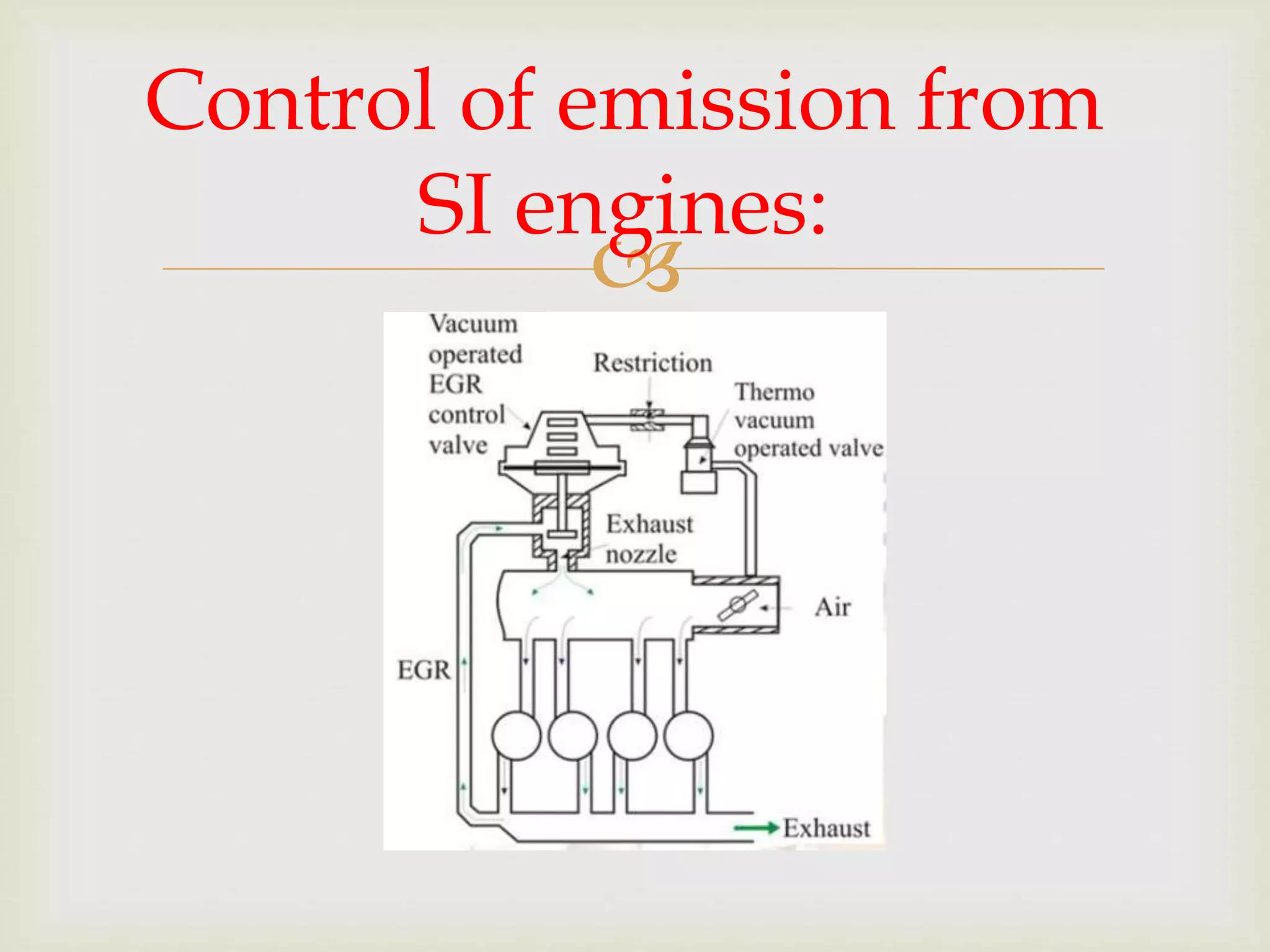

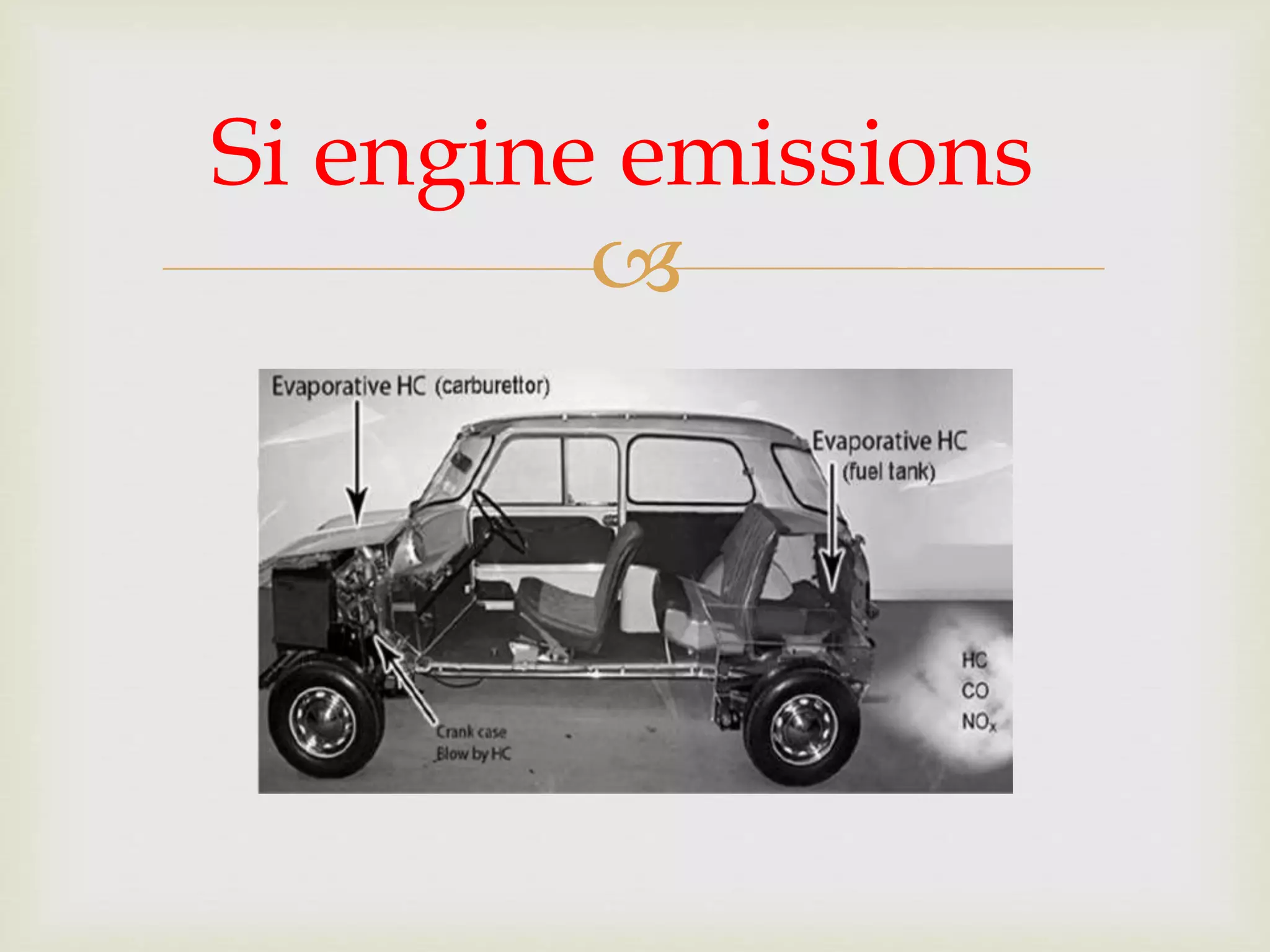

Control of emission from

SI engines:](https://image.slidesharecdn.com/random-151219180618/75/poiiution-formation-and-control-31-2048.jpg)