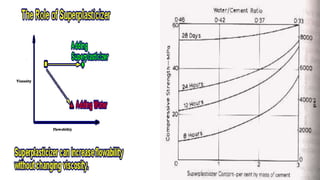

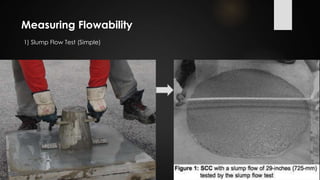

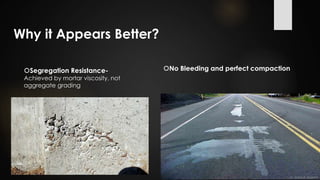

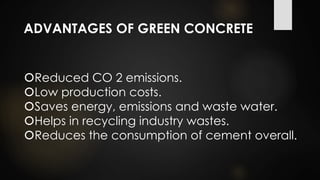

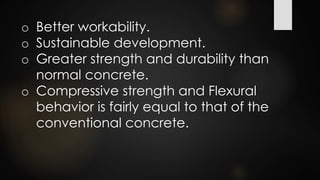

The document discusses non-conventional concrete technologies, highlighting self-compacting concrete and green concrete as innovative alternatives to traditional concrete. These technologies offer benefits such as higher durability, reduced CO2 emissions, and improved workability, while also addressing challenges like cost and the need for better plant control. The conclusion emphasizes that while these advanced concretes may be more expensive initially, they ultimately lead to better performance and lower overall installation effort.