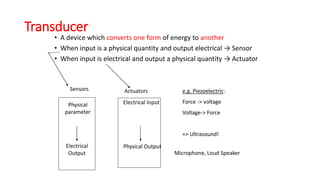

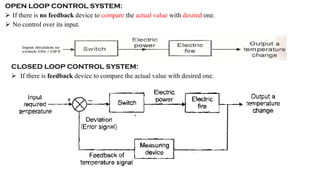

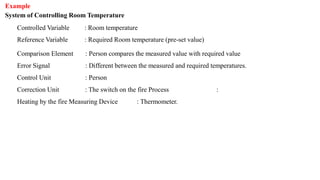

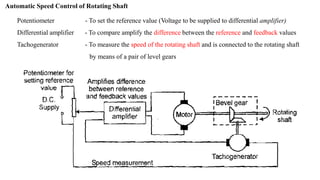

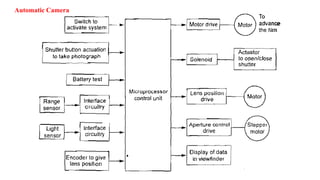

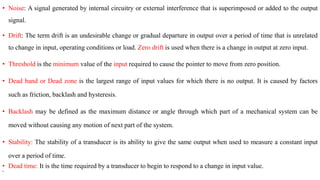

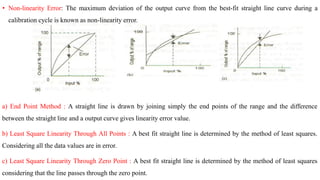

This document provides an overview of mechatronics and measurement systems. It begins with definitions and examples of mechatronics, including its integration of mechanics, electronics, and computing. The key elements of a mechatronic system are described as actuators, sensors, digital control devices, and interfaces. Examples of mechatronic systems include computers, robots, and automobiles. Measurement systems are then introduced as having sensors to detect inputs, signal conditioners to prepare outputs, and displays to present results. Common performance characteristics for both static and dynamic system response are defined.