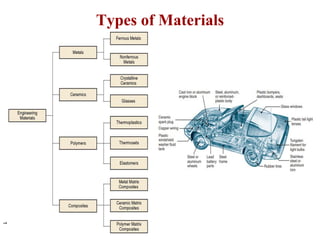

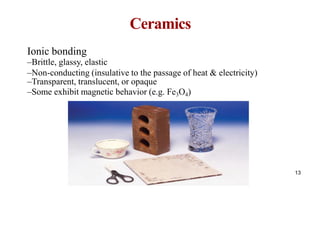

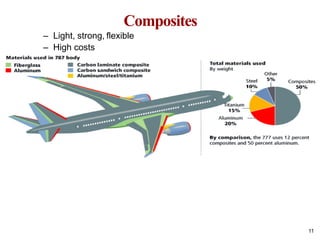

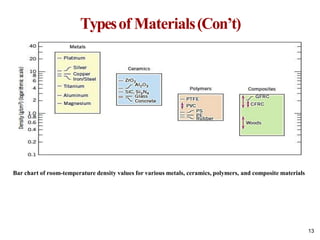

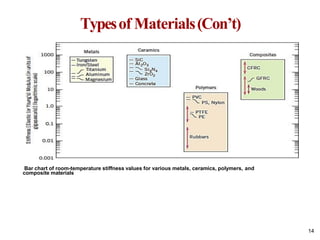

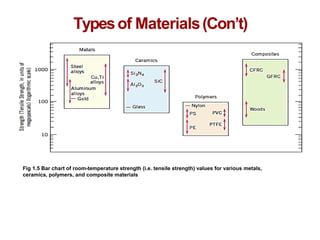

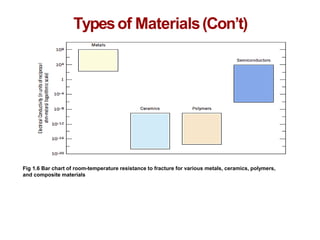

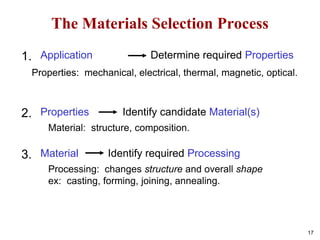

The document outlines a manufacturing technology course that covers engineering materials, manufacturing processes, and practical training in techniques such as casting, welding, and machining. It emphasizes the importance of understanding different materials, including metals, ceramics, polymers, and composites, and their respective properties for effective manufacturing. By the end of the course, students will acquire the necessary skills to analyze and optimize manufacturing operations, making informed decisions on materials and quality control.