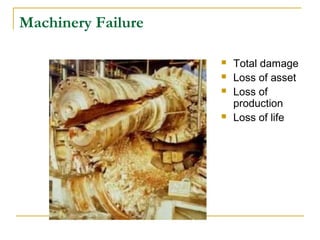

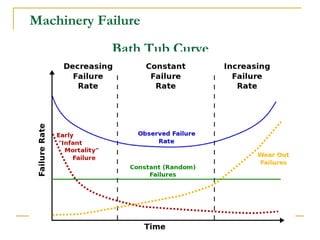

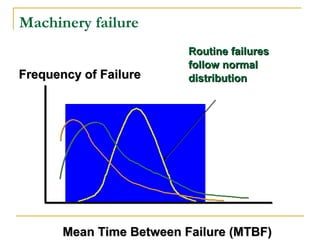

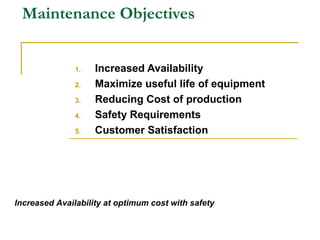

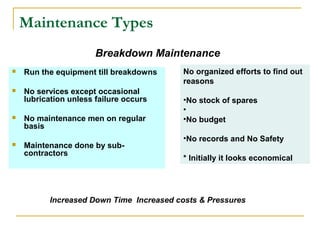

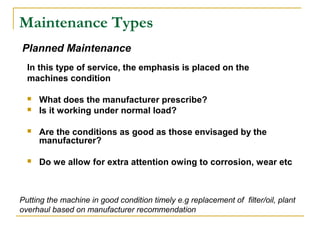

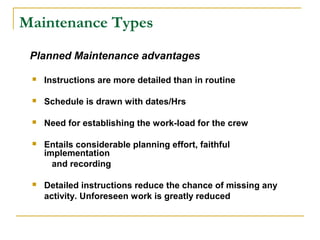

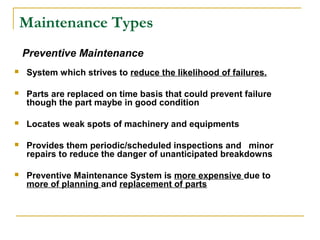

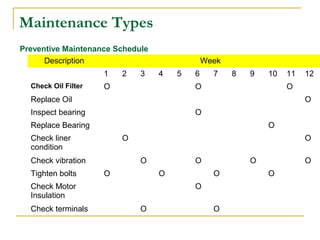

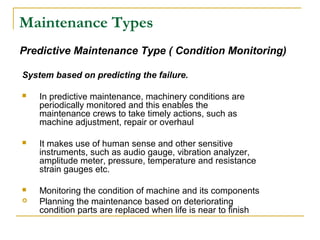

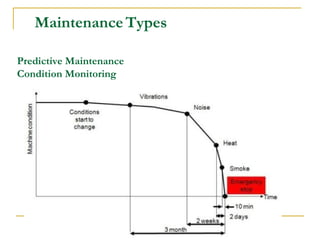

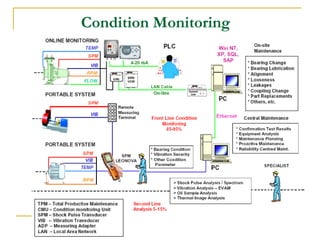

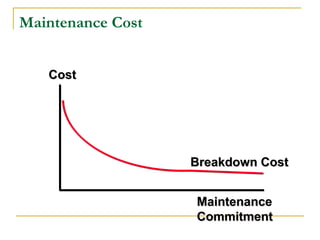

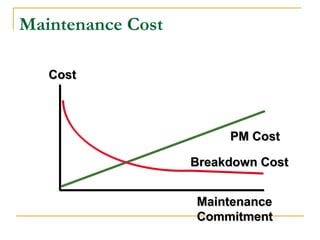

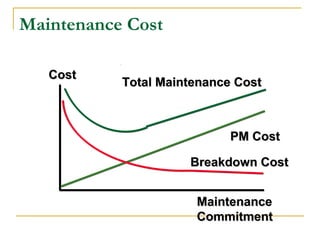

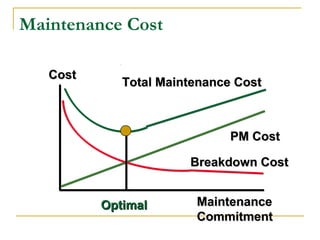

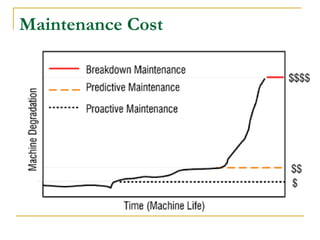

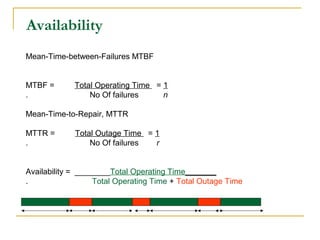

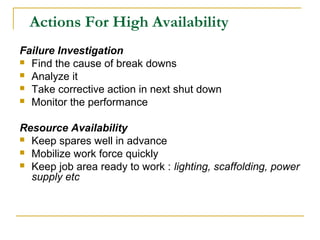

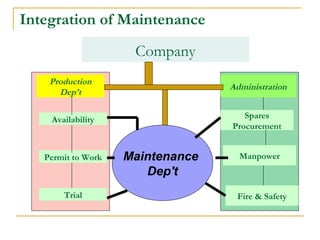

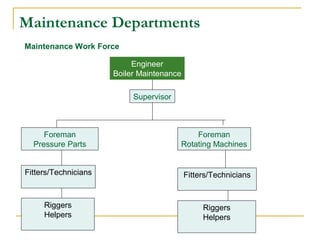

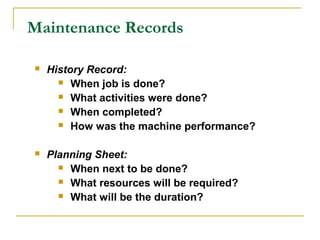

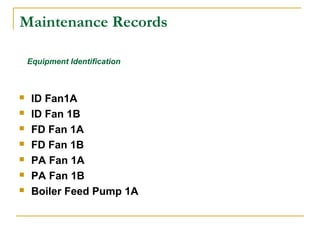

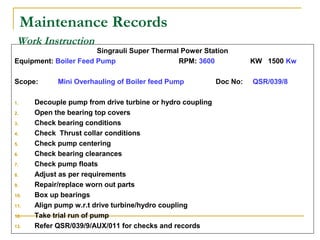

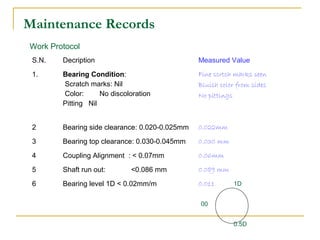

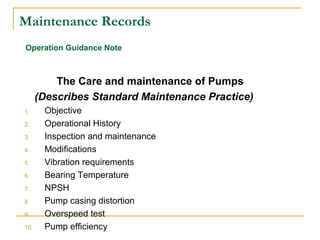

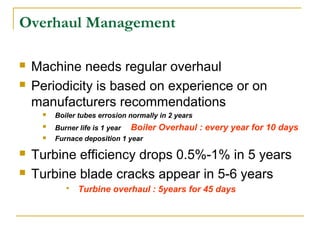

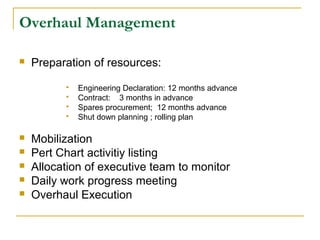

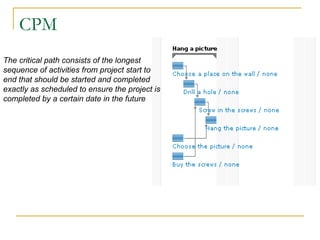

The document provides an overview of a presentation on maintenance systems. It discusses key topics like machinery failure, maintenance objectives, types of maintenance including breakdown, planned, preventive, and predictive maintenance. It covers maintenance cost analysis, availability calculation, integration of maintenance with other departments. Specific sections describe maintenance departments and roles, engineers' duties, use of computer systems, importance of maintenance records and overhaul management. The document aims to outline important aspects of effective maintenance systems for industrial operations.