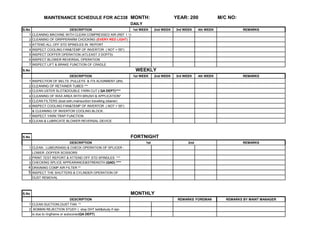

This document outlines a maintenance schedule for an AC338 machine over various time periods (daily, weekly, fortnightly, monthly, quarterly, half-yearly, yearly, and more than yearly). It details specific maintenance tasks to be completed for the machine, including cleaning, inspections, lubrications, and replacements. Tasks range from cleaning the machine with compressed air daily to greasing cam followers every 2 years.