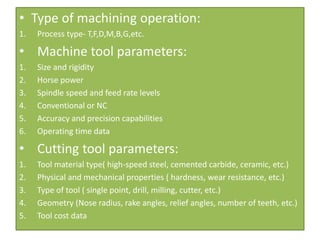

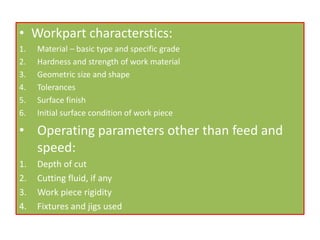

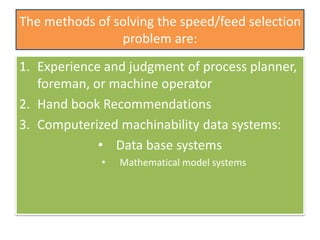

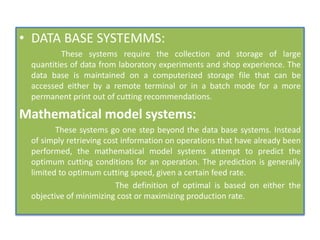

Machinability data systems aim to select the proper cutting speed and feed rate for a machining operation given characteristics of the operation such as the type of machining, machine tool, cutting tool, workpiece, and other parameters besides speed and feed. There are two main types of machinability data systems: database systems which store data from experiments and experience to provide recommendations, and mathematical model systems which go beyond simply retrieving data by attempting to predict optimal cutting conditions through mathematical models.