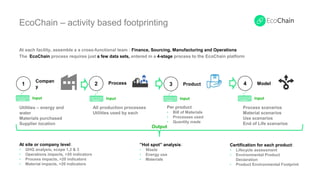

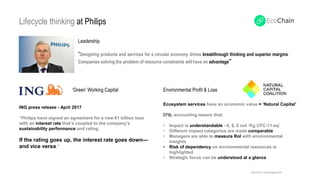

The document discusses the importance of lifecycle thinking and measuring environmental impact at every stage of a product's lifecycle to support circular economy initiatives. It highlights the Ecochain process, which incorporates cross-functional collaboration and data analysis to address environmental impacts, and includes examples such as Philips' sustainability-linked financial agreements. Key metrics are focused on reducing overall environmental footprints while enhancing the understanding of natural capital's economic value.