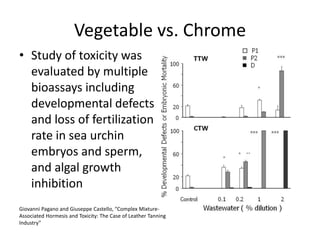

Leather tanning is the process of treating raw animal hides to prevent decay and make them suitable for use. It involves soaking, hair removal, pickling, and tanning the hides through either the more common chrome tanning process or vegetable tanning. Chrome tanning uses chemicals containing trivalent chrome to tan the hides over 8 hours, while vegetable tanning uses tannic acid extracted from tree bark over 2-4 days. After tanning, the hides undergo further processing like dyeing, rolling, and finishing to produce leather. Tanning can cause environmental impacts through air and water pollution from chemicals used. Methods to reduce impacts include reusing water, recovering chrome, using more efficient processes, and choosing vegetable tanning