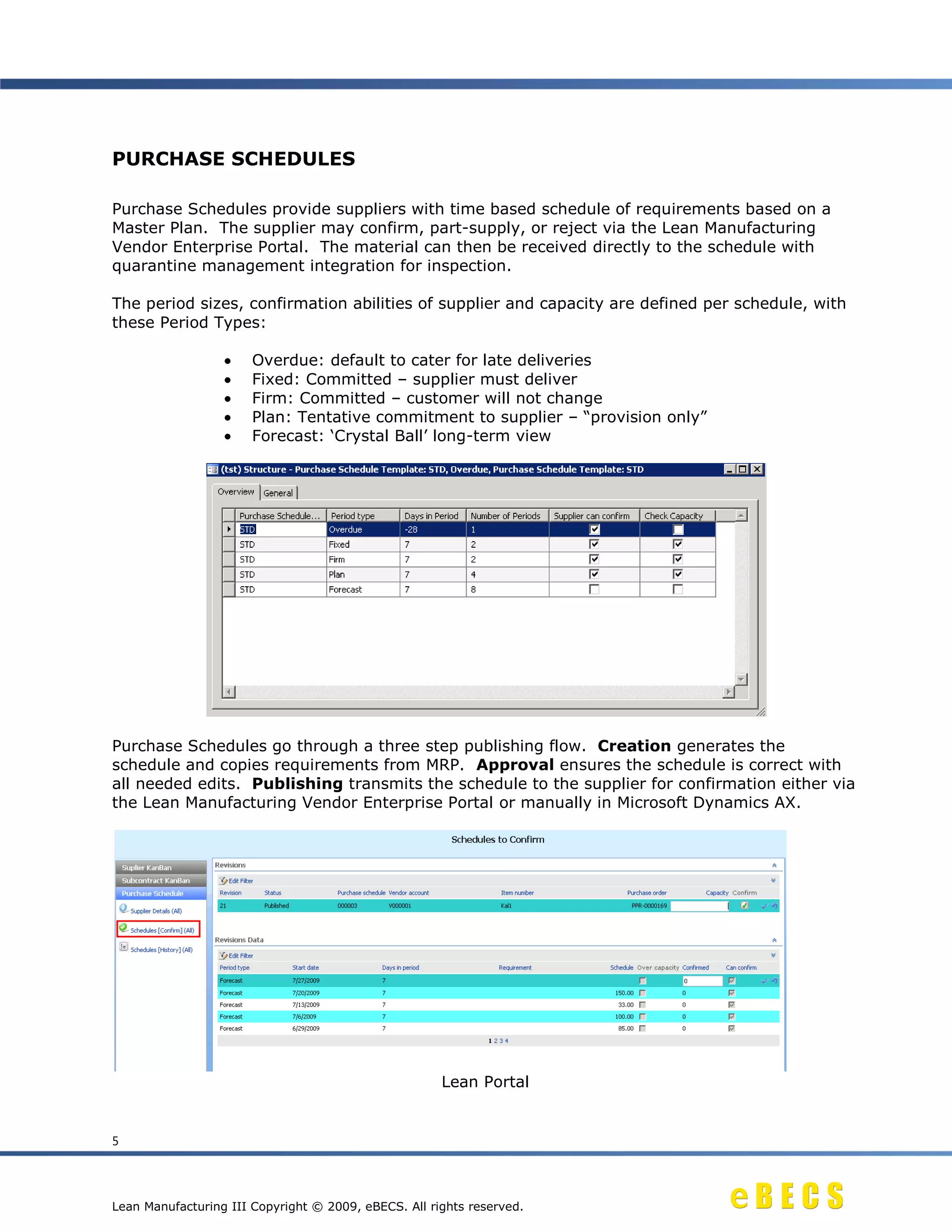

The document discusses additional Lean Manufacturing functionality available in Lean Manufacturing III to further leverage Lean practices in Microsoft Dynamics AX. Key capabilities covered include vendor managed inventory, purchase schedules, flow schedules, Lean alerting, pull-point processing, and integration with eBECS and the Lean Centre of Excellence. Lean Manufacturing III builds on Lean Manufacturing I and II to provide an institutionalized Lean solution for global manufacturers.