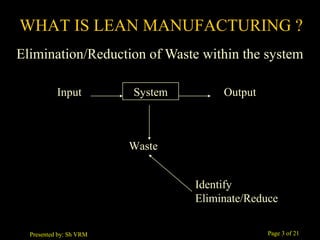

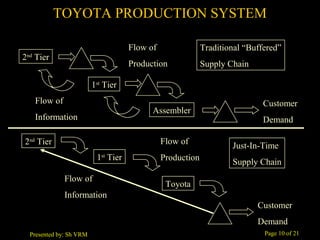

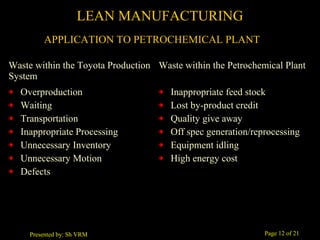

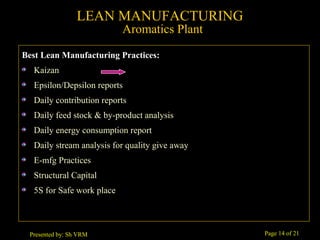

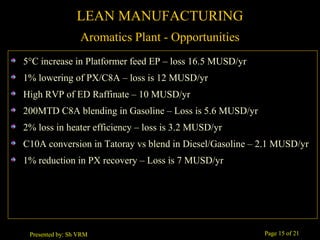

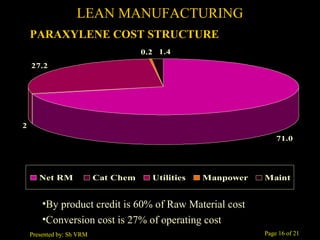

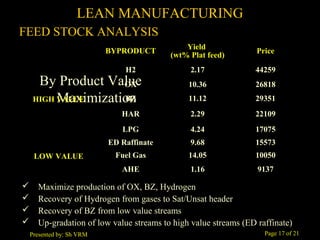

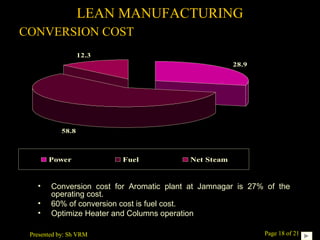

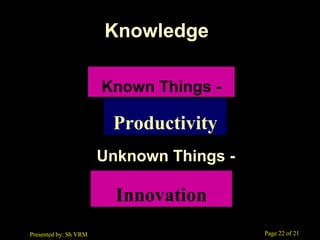

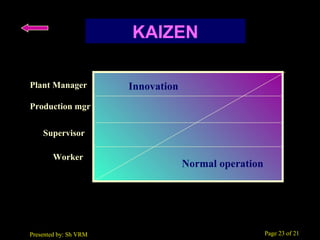

This document discusses lean manufacturing and its application to petrochemical plants. It defines lean manufacturing as focusing on eliminating waste, improving productivity, quality and optimizing resources. The document outlines various lean tools like 5S, kaizen, total productive maintenance and their use. It analyzes sources of waste in petrochemical plants and provides examples of applying lean thinking to maximize byproduct value, reduce conversion costs and implement business cases around market optimization, product development and opportunity realization. The overall objective is to translate lean philosophy for continual improvement in petrochemical operations.