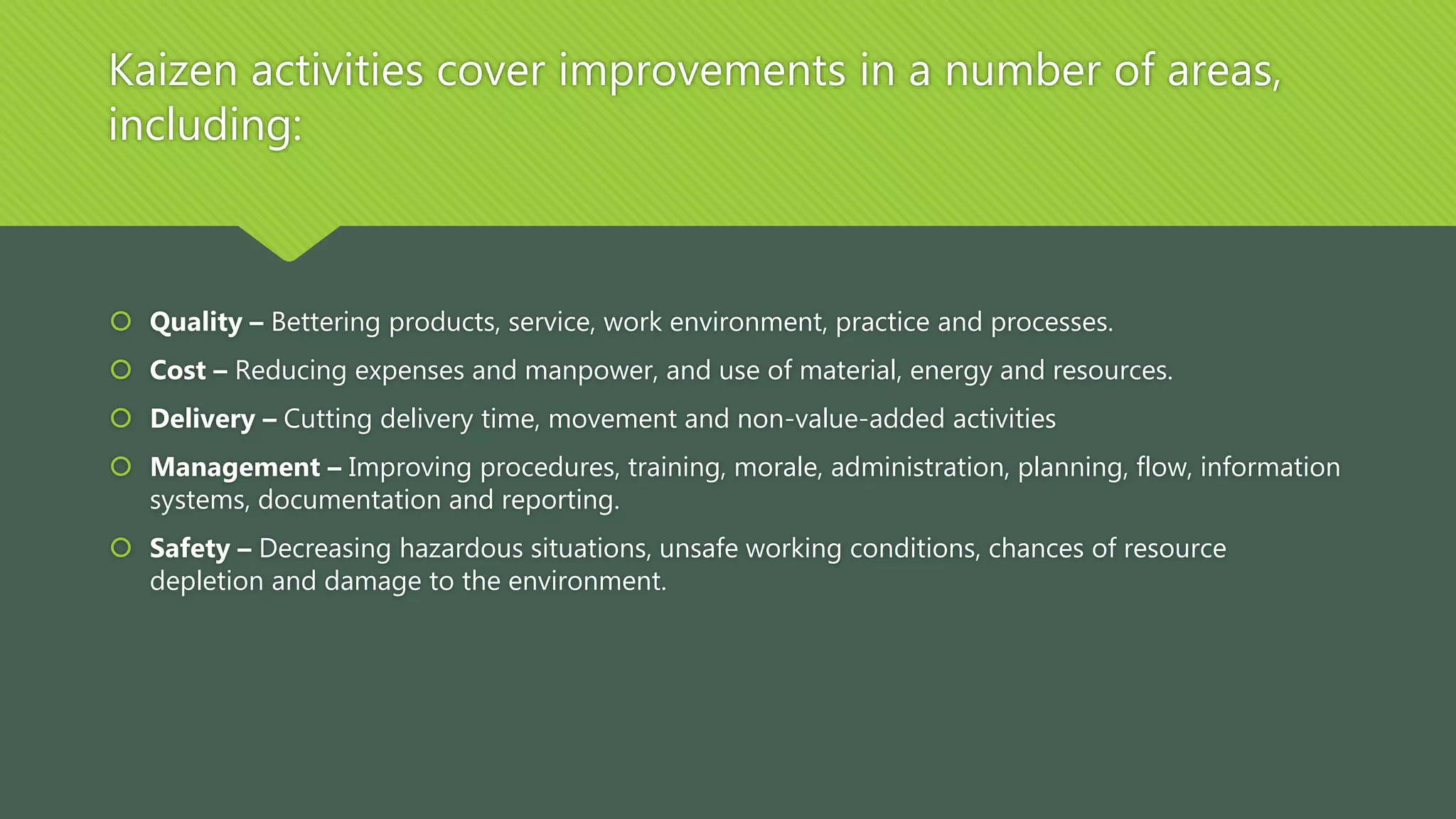

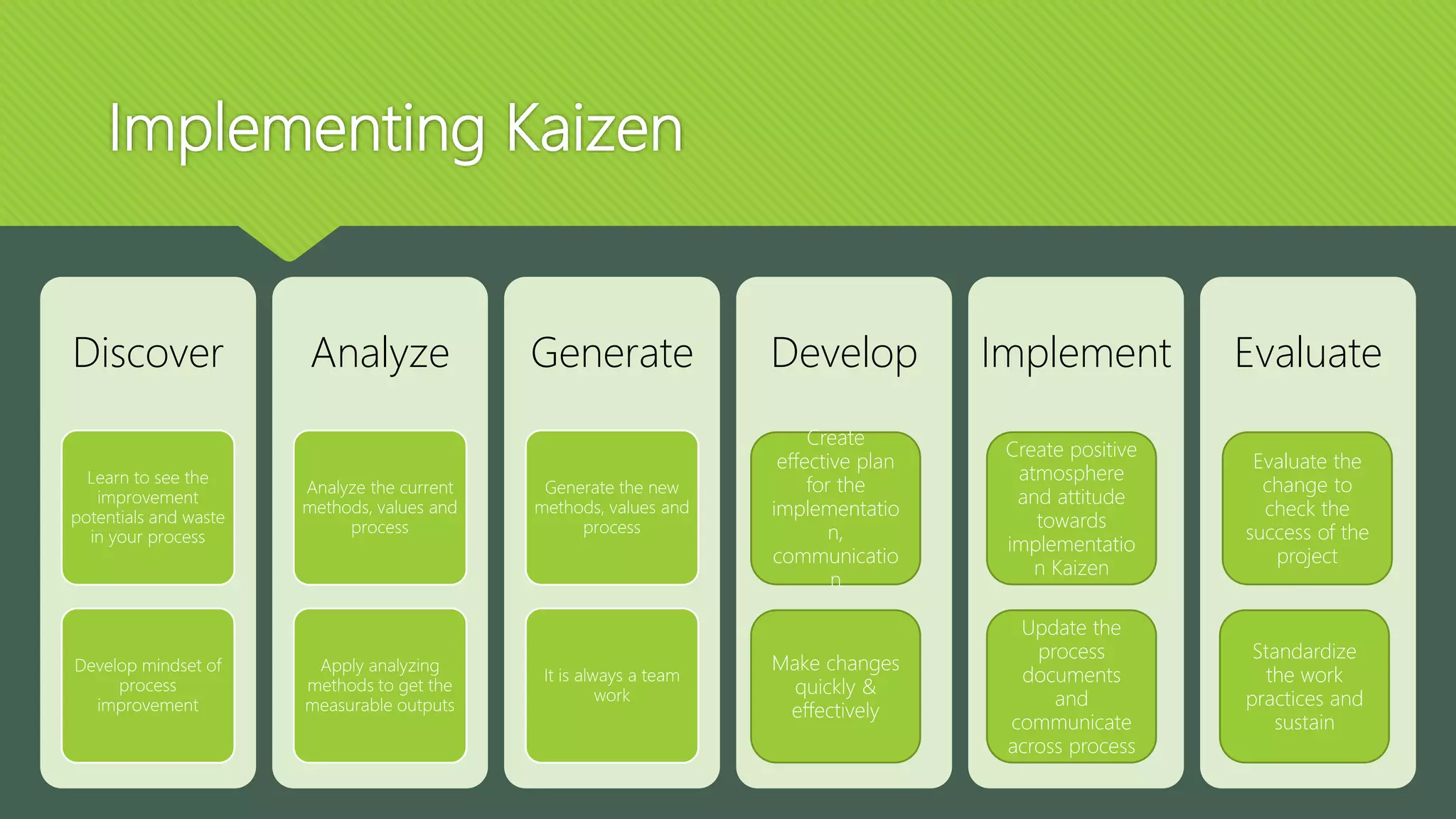

Kaizen refers to continuous improvement of processes through small, incremental changes. It comes from Japanese words meaning "improvement" and "change for the better." There are two main approaches: flow kaizen evaluates entire value streams, while process kaizen focuses workers on small daily improvements. Kaizen aims to enhance quality, reduce costs and delivery times, and improve management, safety, and other areas. It is implemented through discovering improvement opportunities, analyzing current methods, generating new ideas in teams, developing and implementing plans, then evaluating and standardizing changes. The benefits of kaizen include improved productivity, quality, safety, lower costs, and higher customer satisfaction through these continuous small improvements.