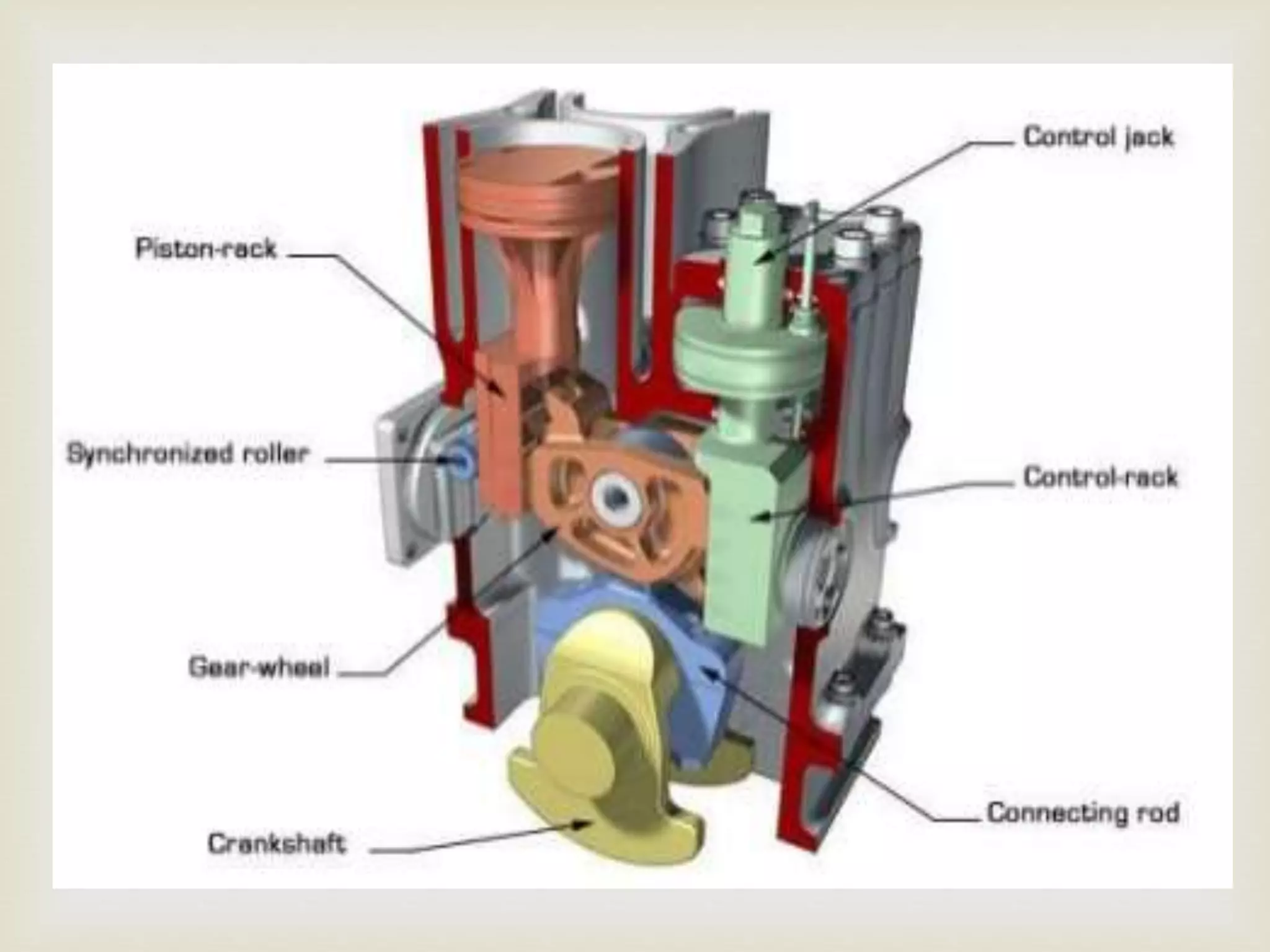

This document discusses variable compression ratio diesel engines and their performance analysis. It introduces variable compression ratio technology which allows the compression ratio of an engine to be adjusted while operating based on load demands. This increases fuel efficiency by using higher ratios for low loads and lower ratios for high loads. The document covers compression ratios, the advantages of variable compression like increased fuel efficiency and reduced emissions, and disadvantages such as high costs and unproven reliability. It concludes that variable compression ratio engines have great potential to improve power and fuel economy when combined with other technologies.