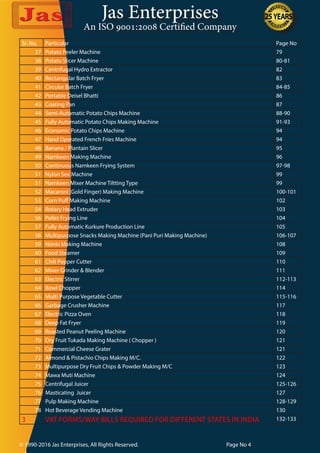

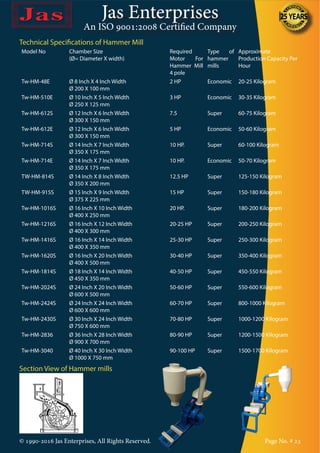

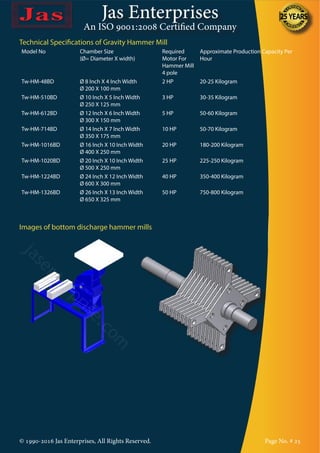

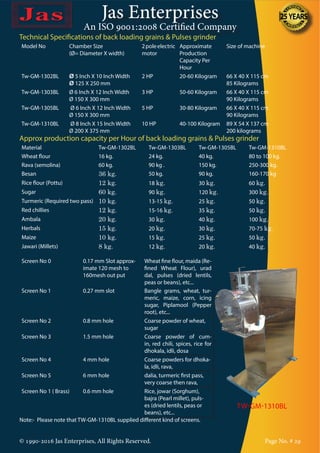

Jas Enterprises is an ISO 9001:2008 certified company specializing in food processing and size reduction equipment since 1990, operating from Ahmedabad, India. They offer a comprehensive range of products including mini dal mills, grinding machines, and various food processing solutions tailored to customer needs, while emphasizing quality, innovation, and customer satisfaction. The company also provides turnkey project management and has a strong presence in both domestic and international markets, with a commitment to continuous improvement and customer-centric services.