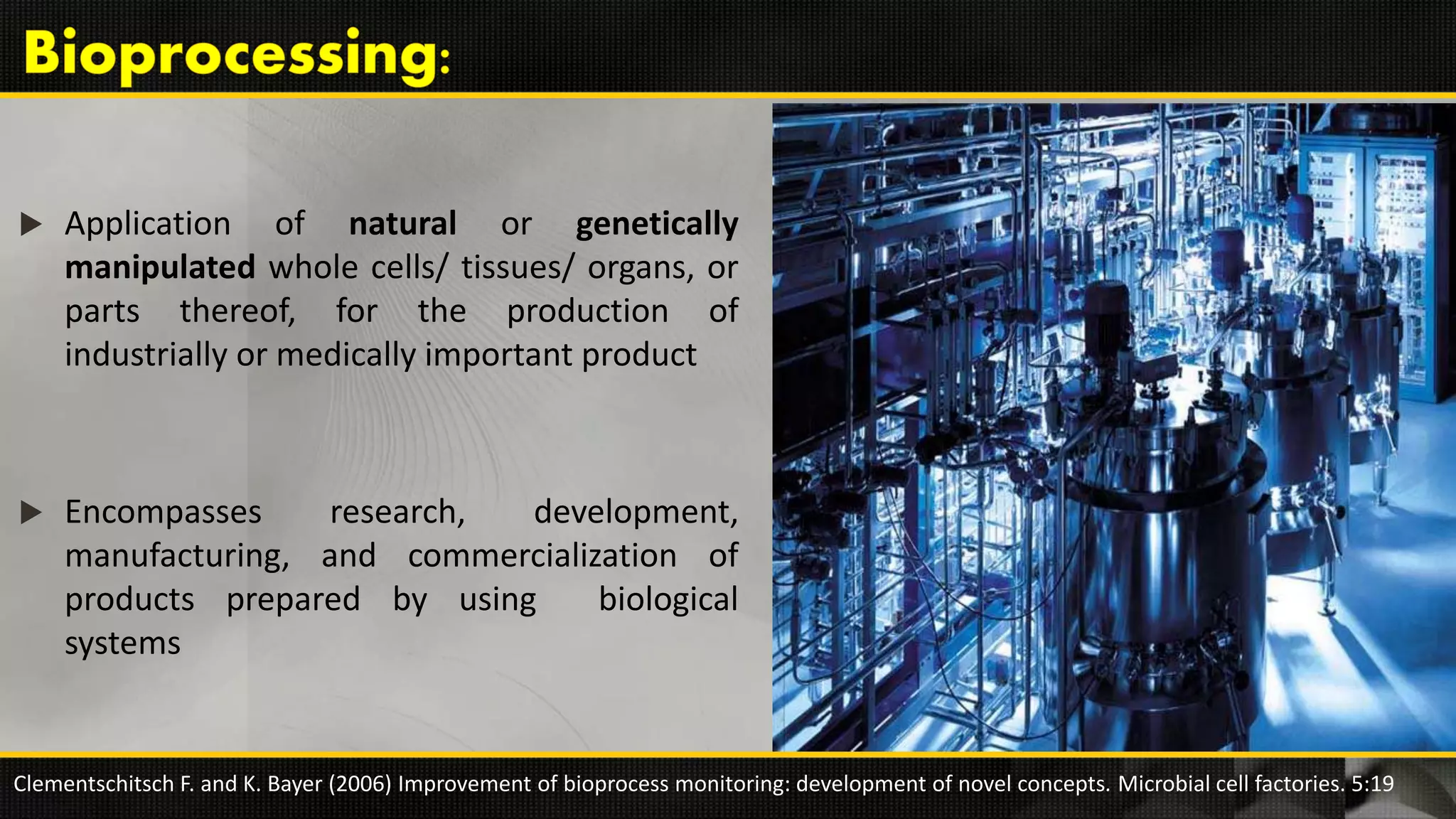

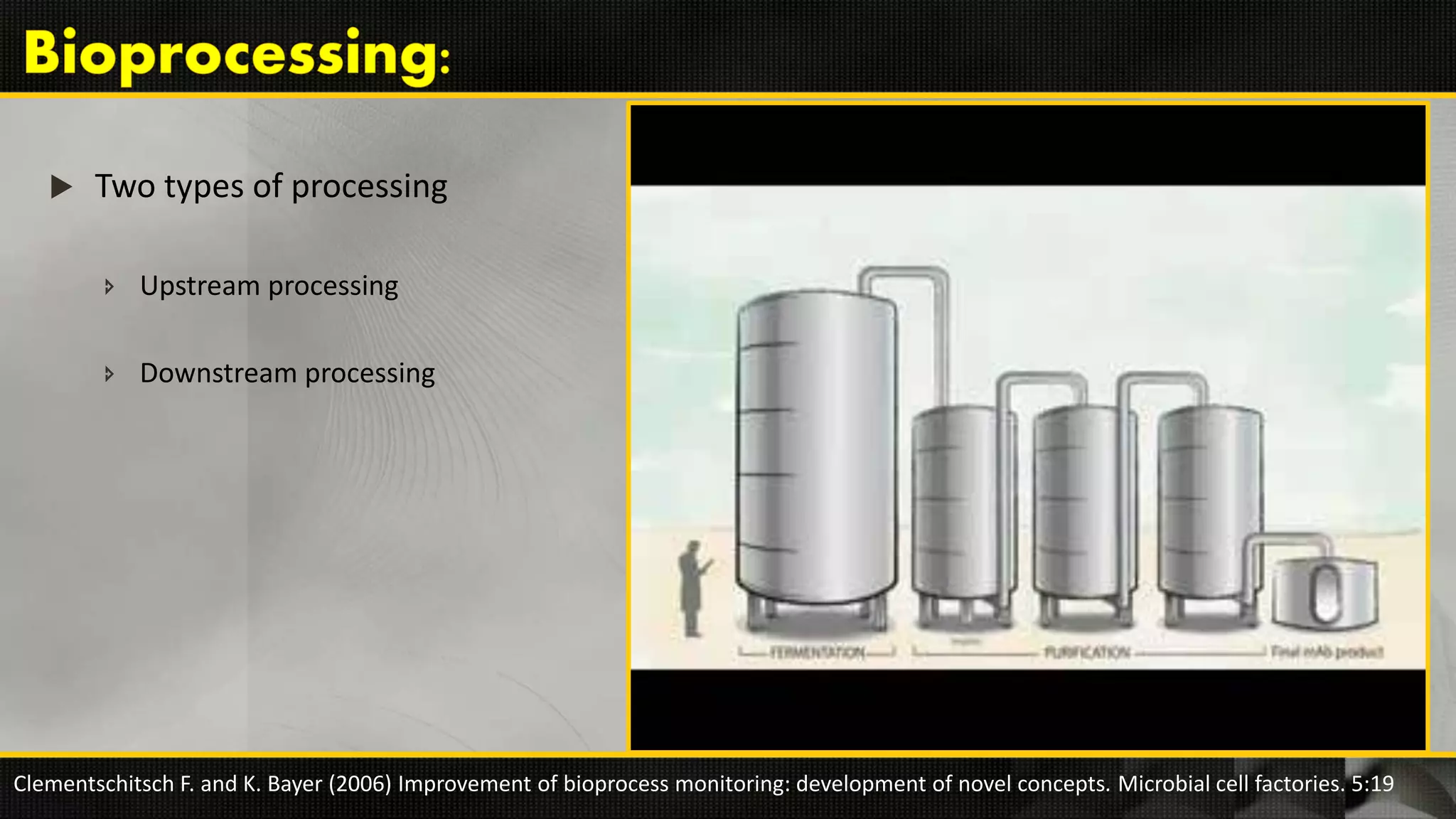

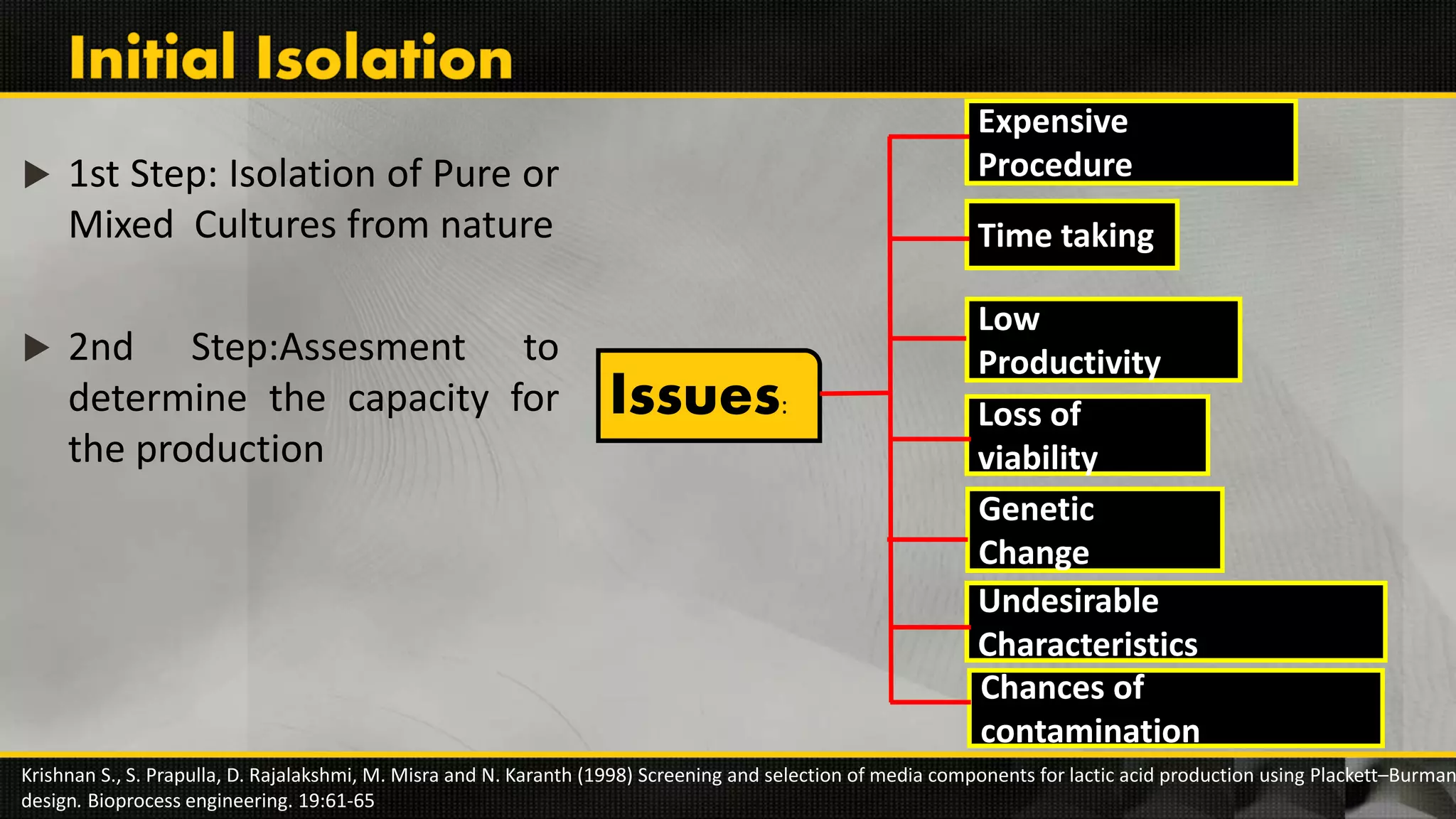

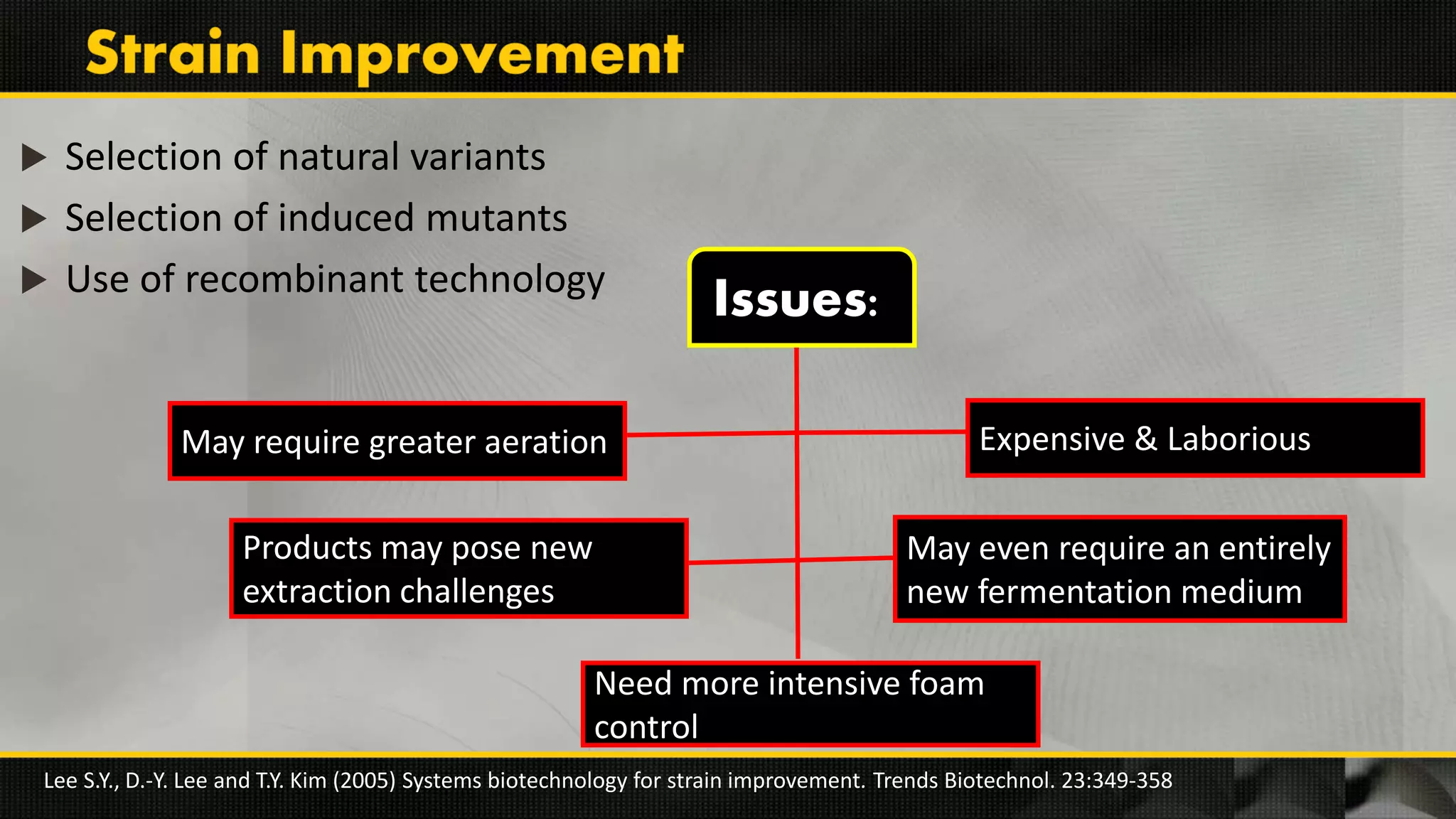

1. Bioprocessing involves using microorganisms to produce industrial or medical products. There are many issues that can arise during isolation, strain improvement, and production of microorganisms.

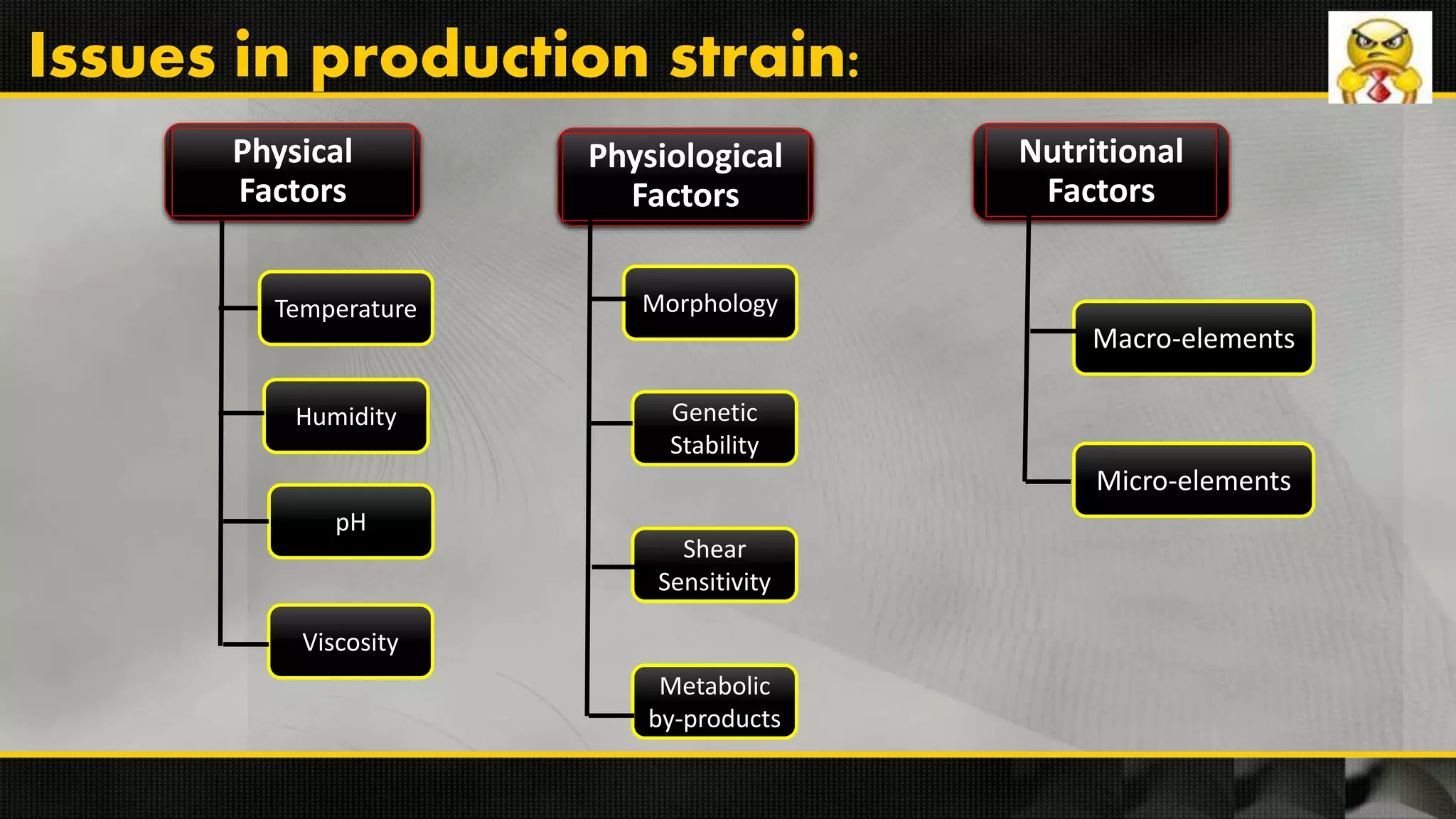

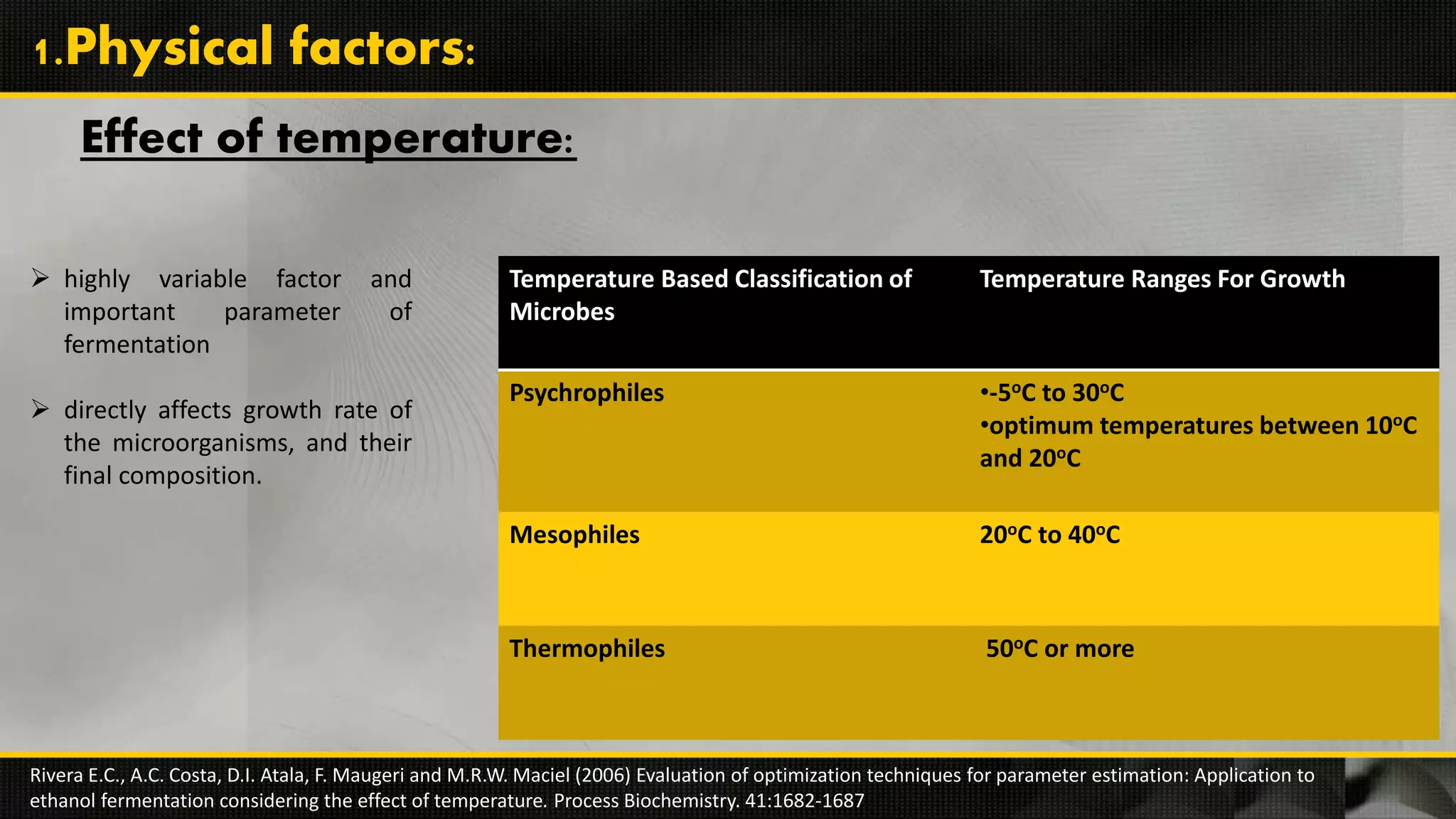

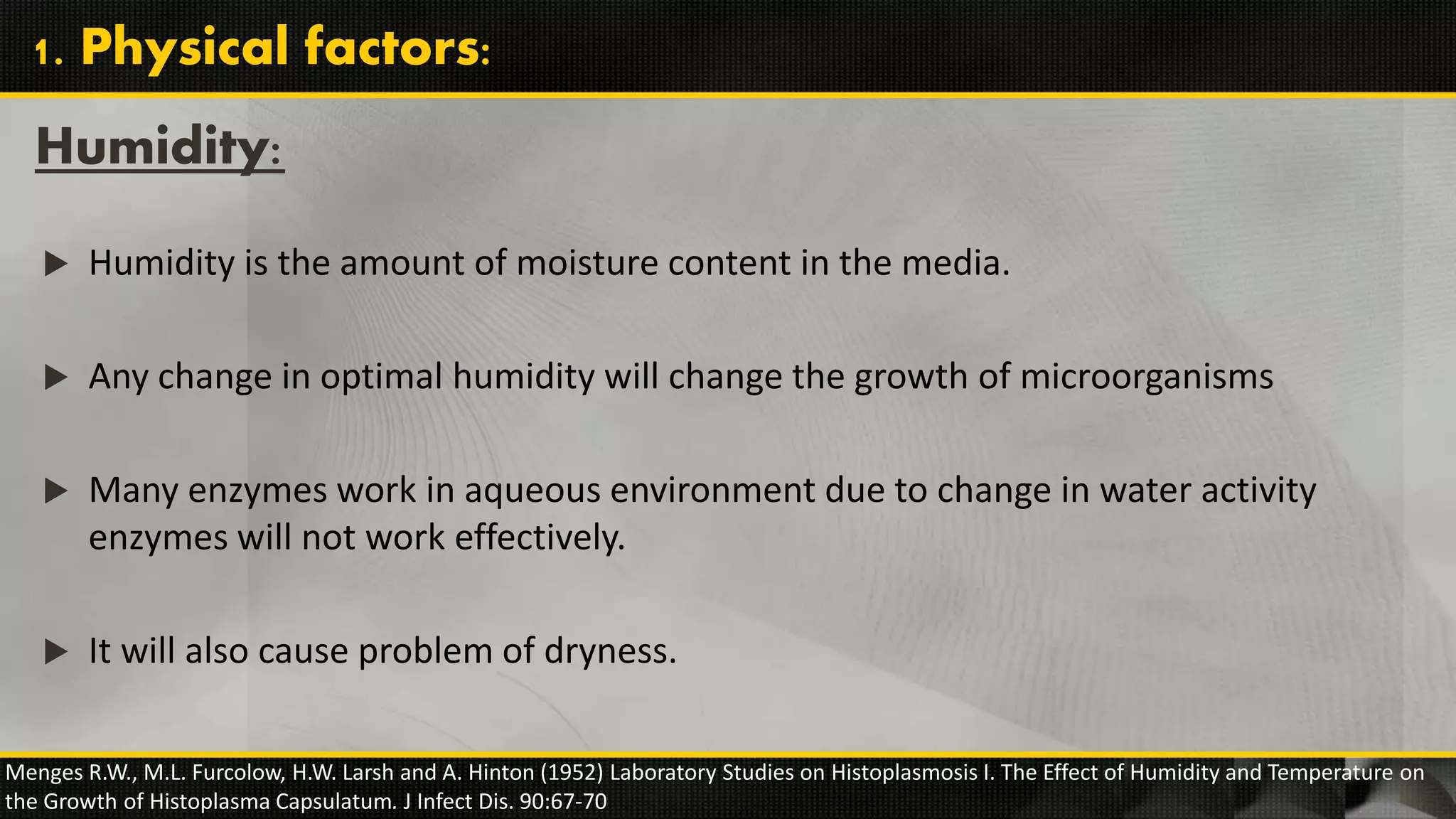

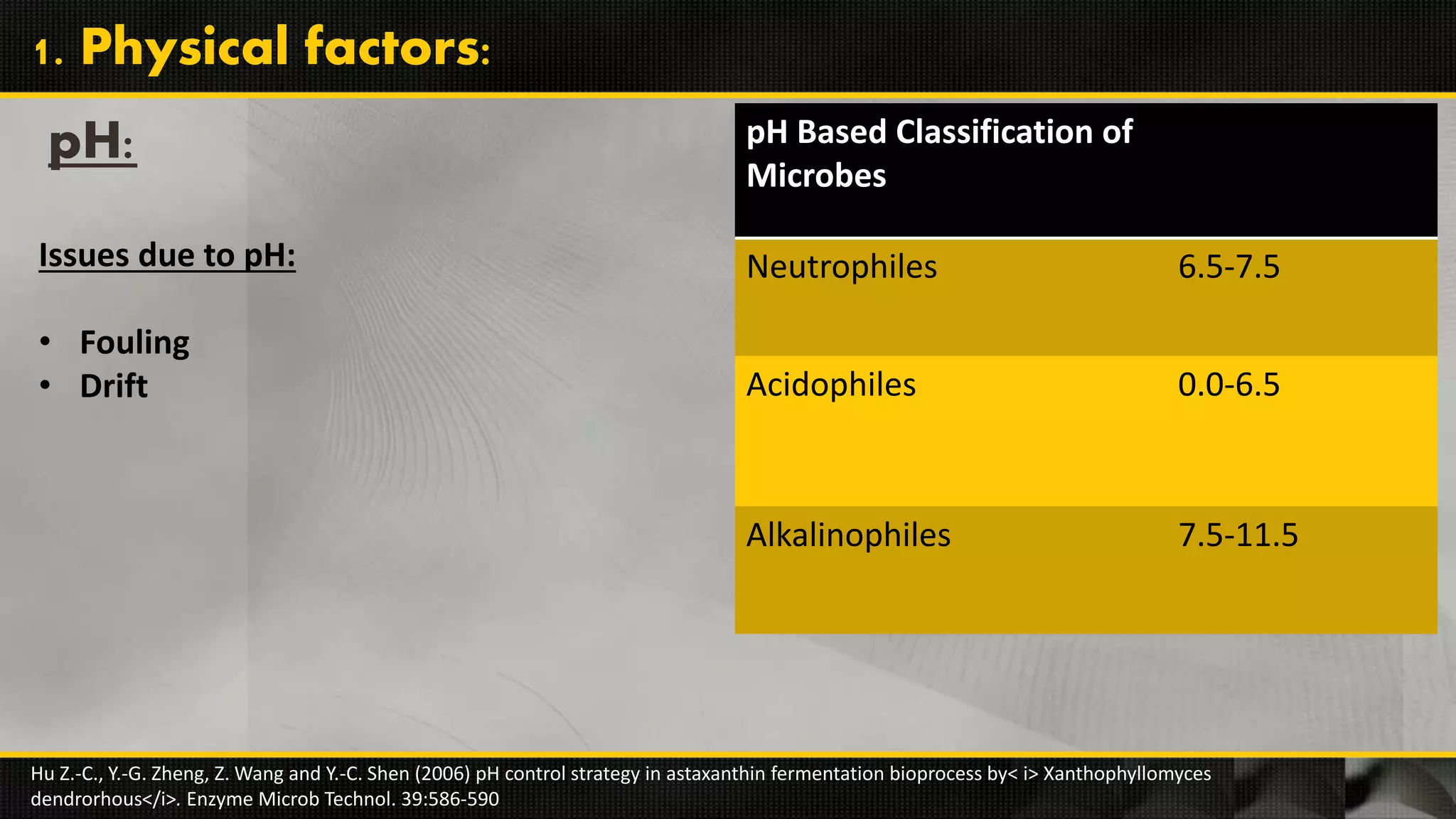

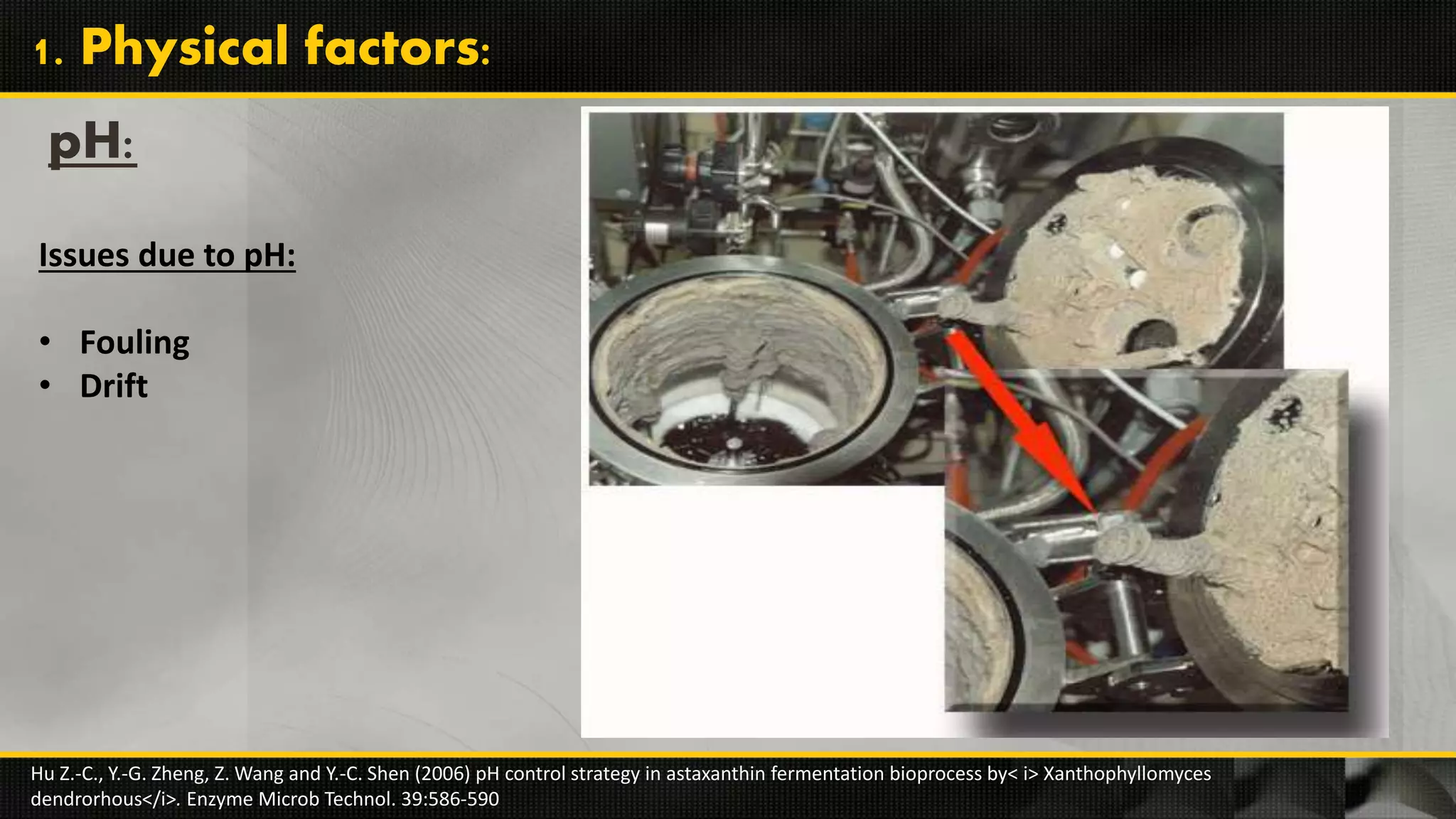

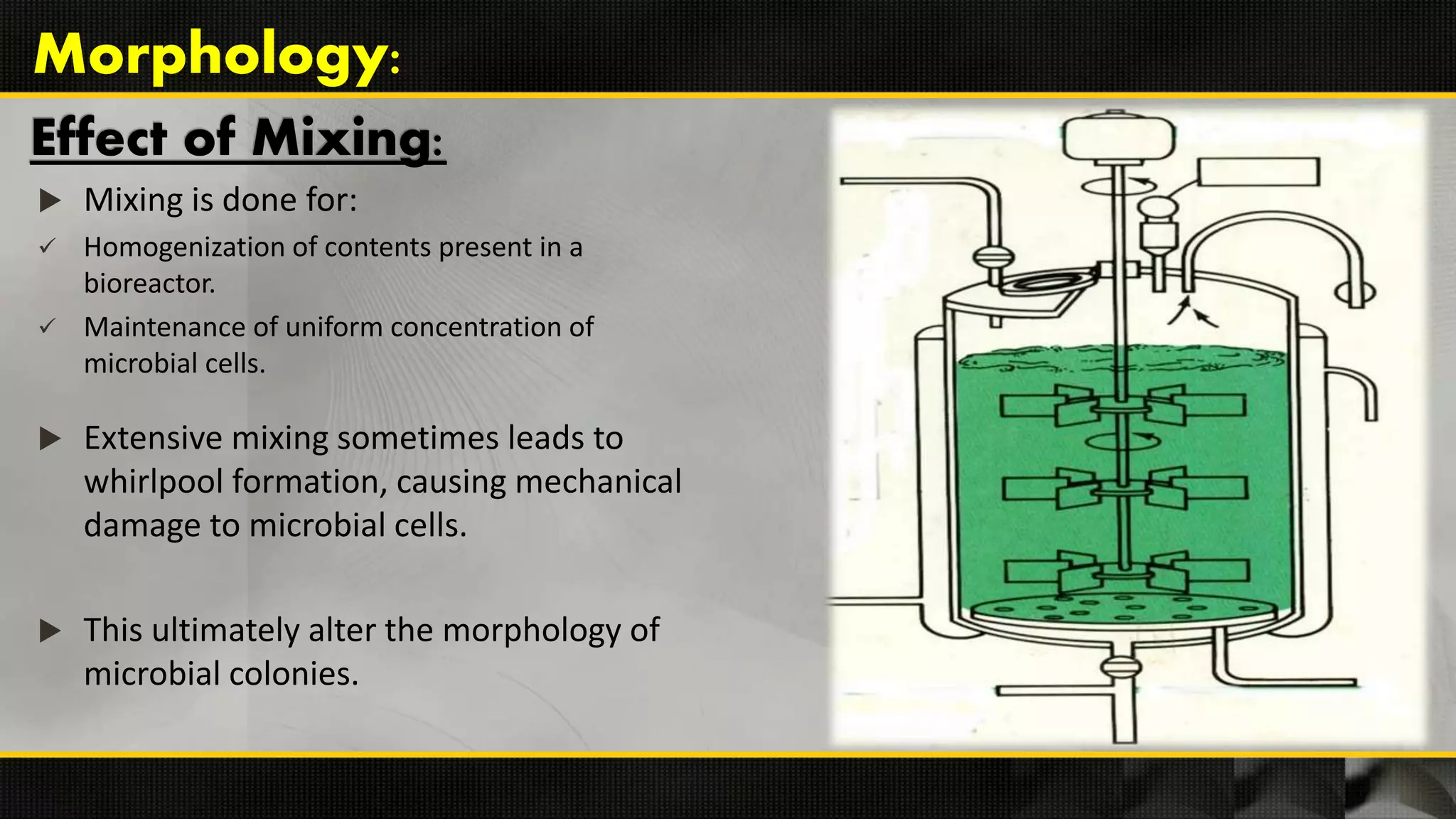

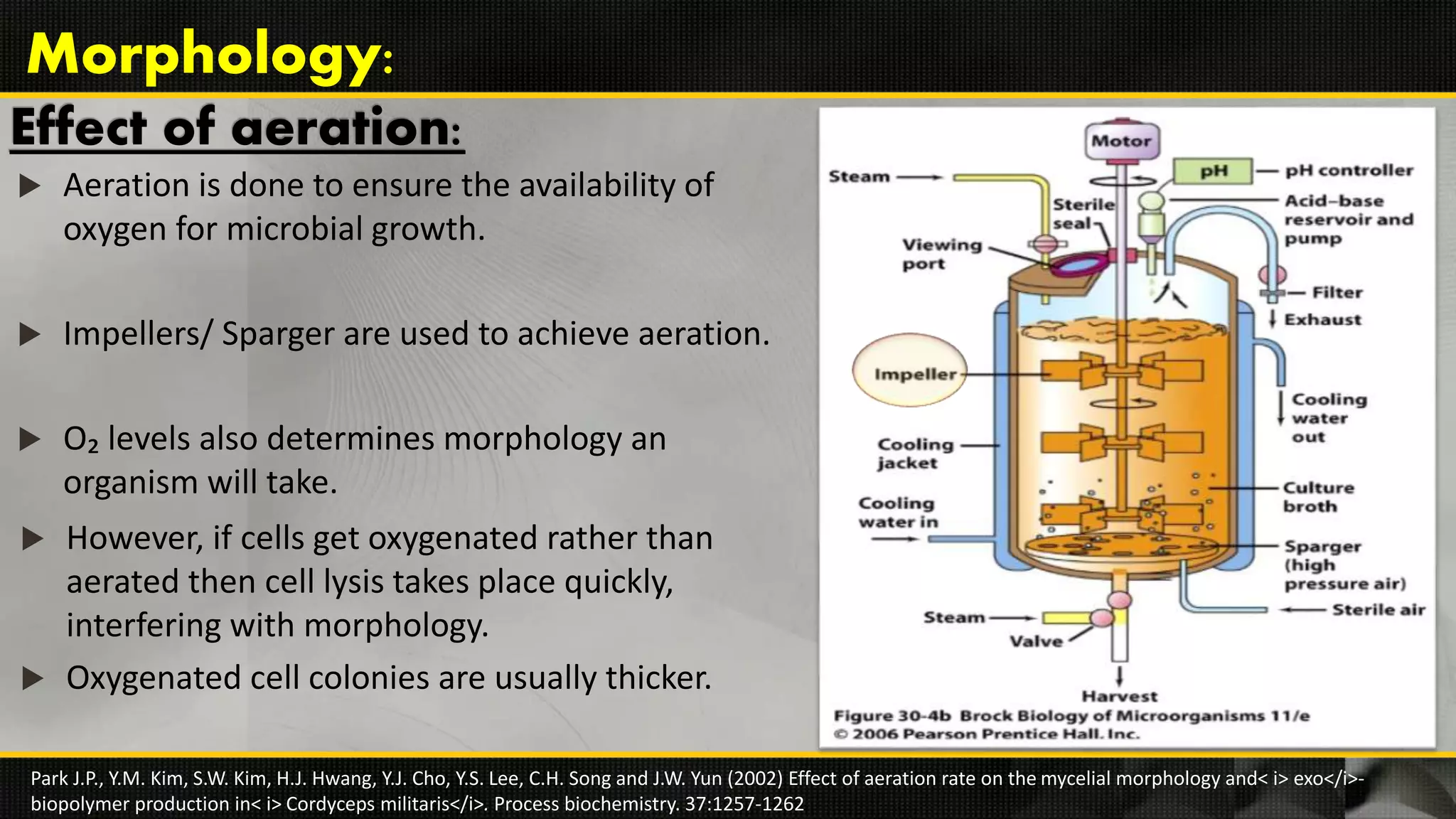

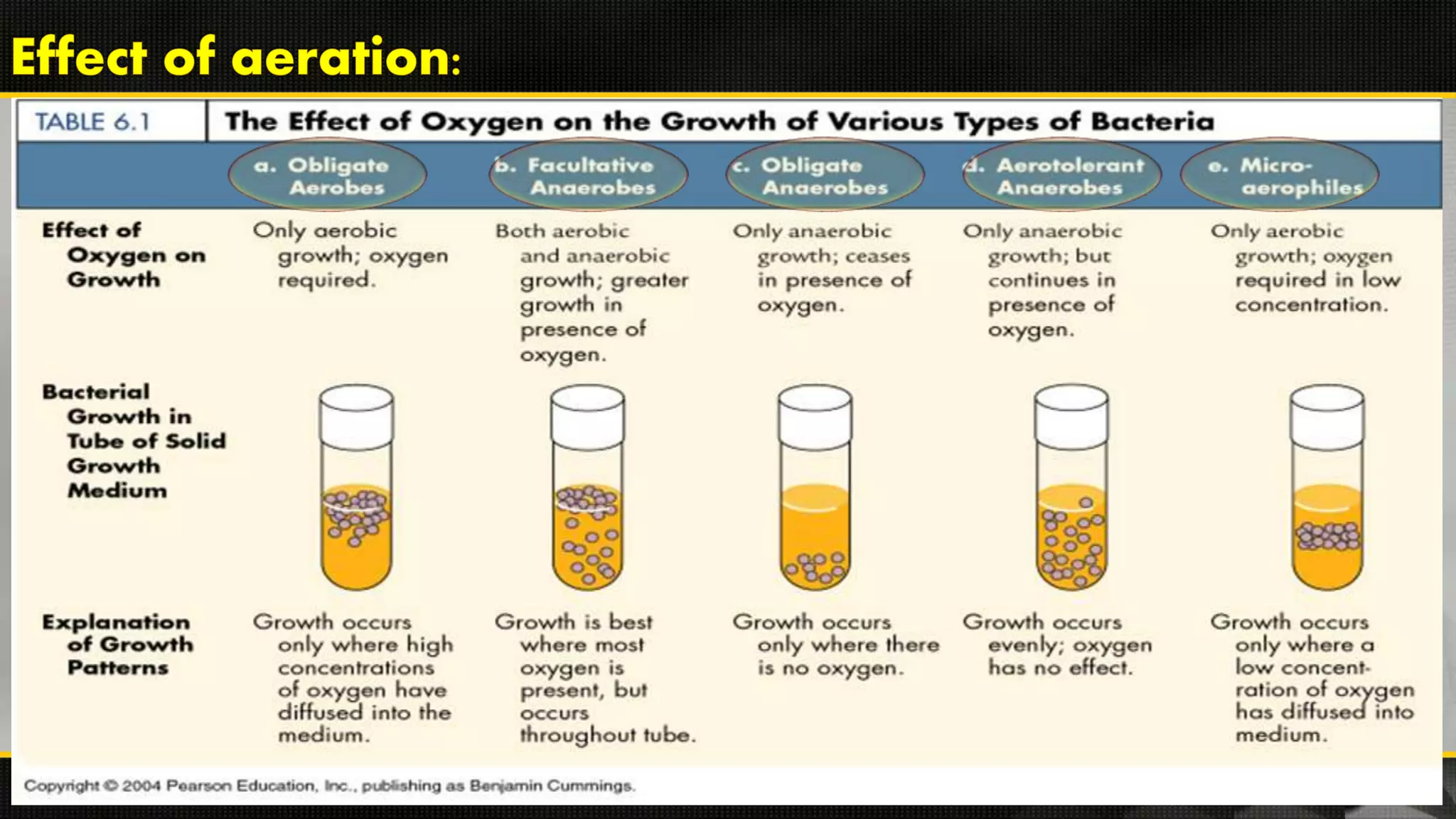

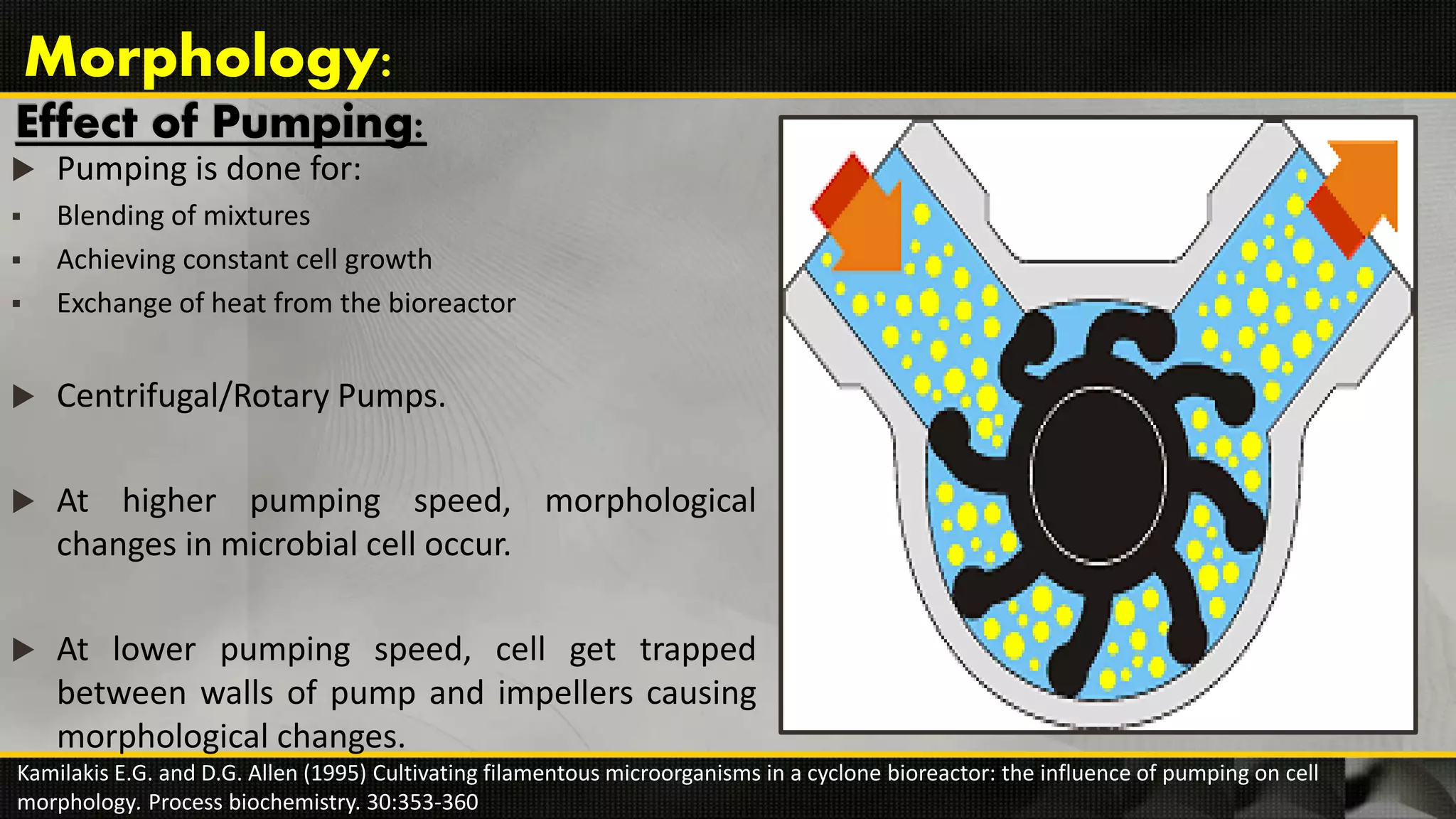

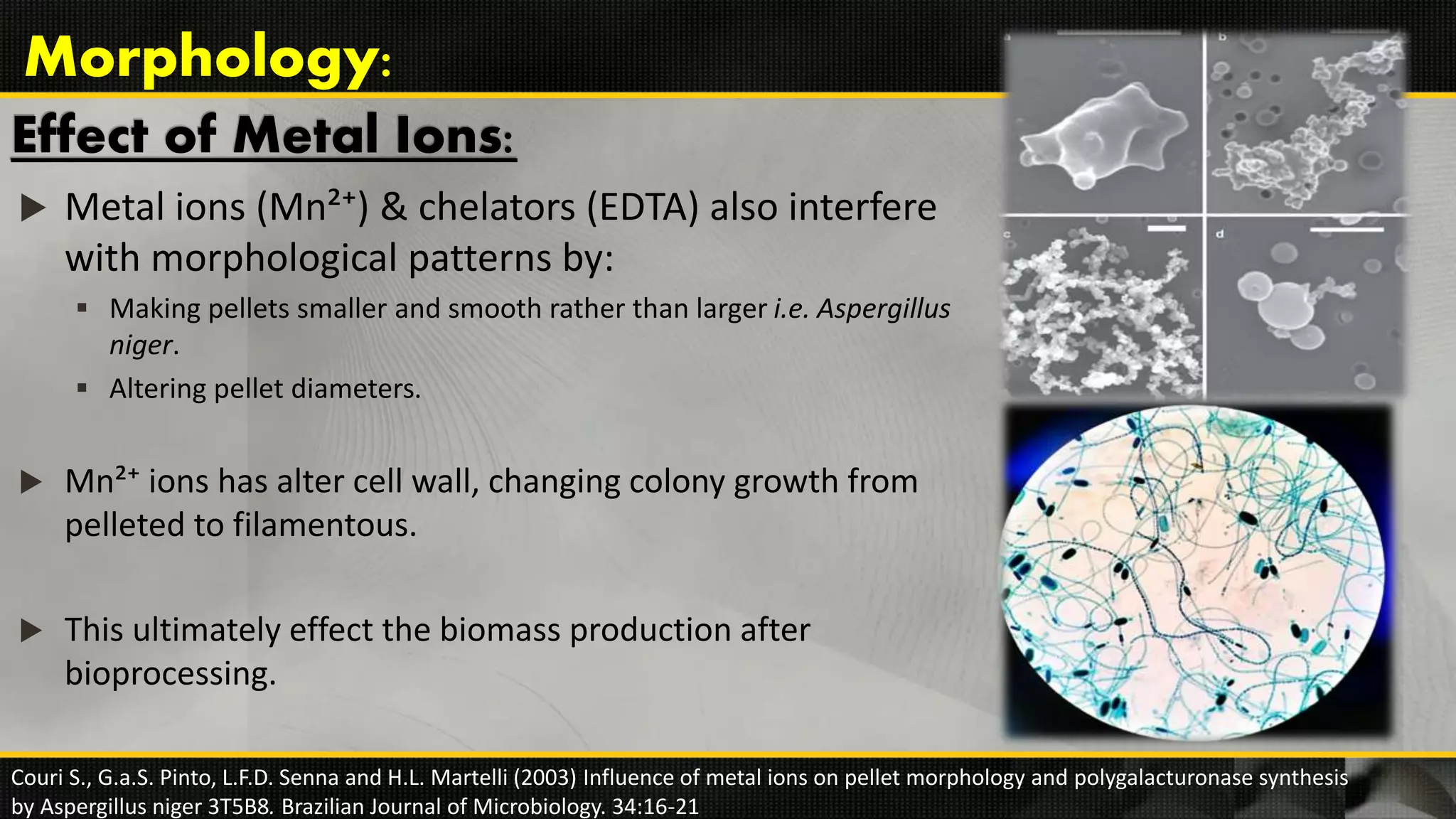

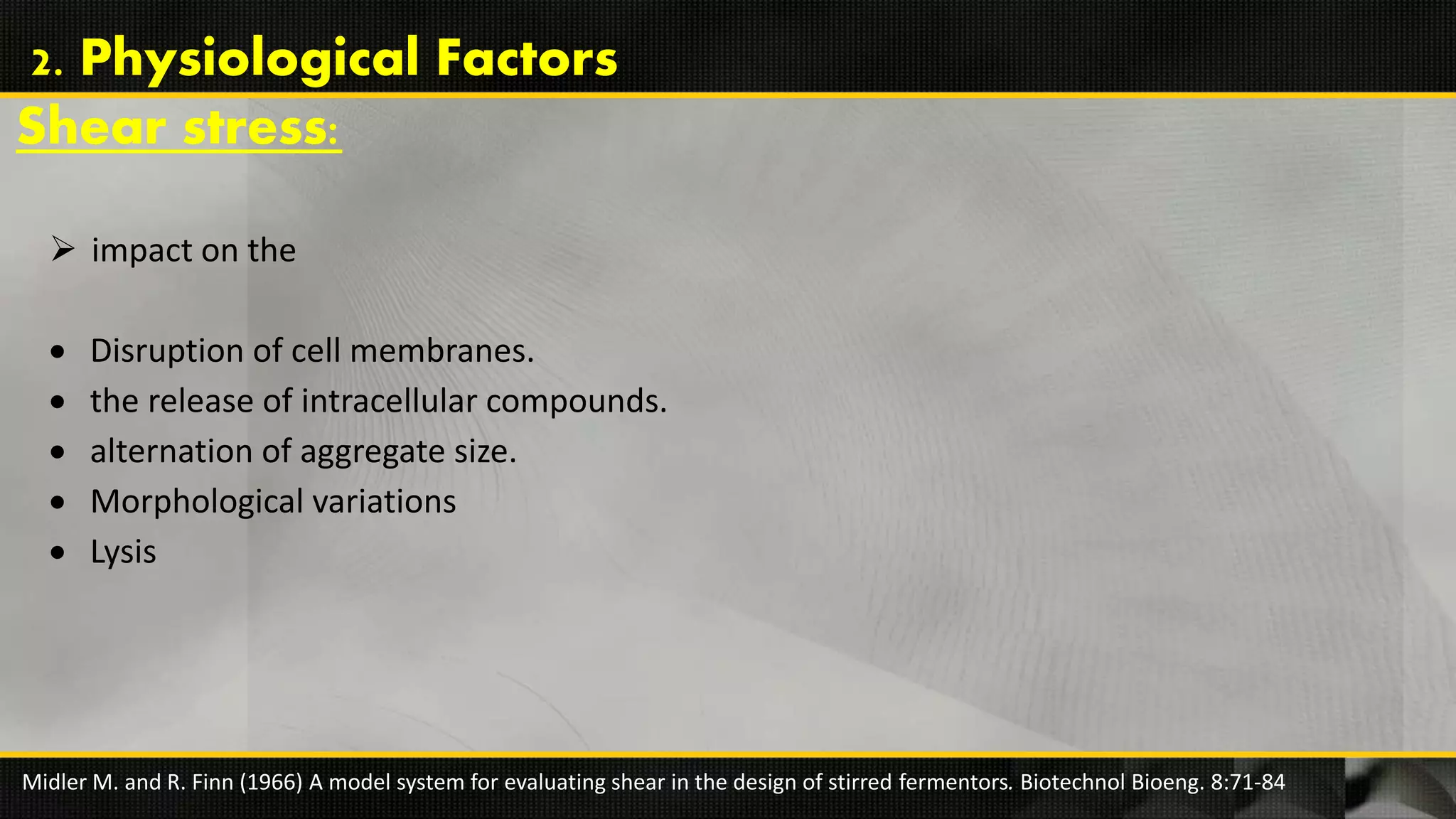

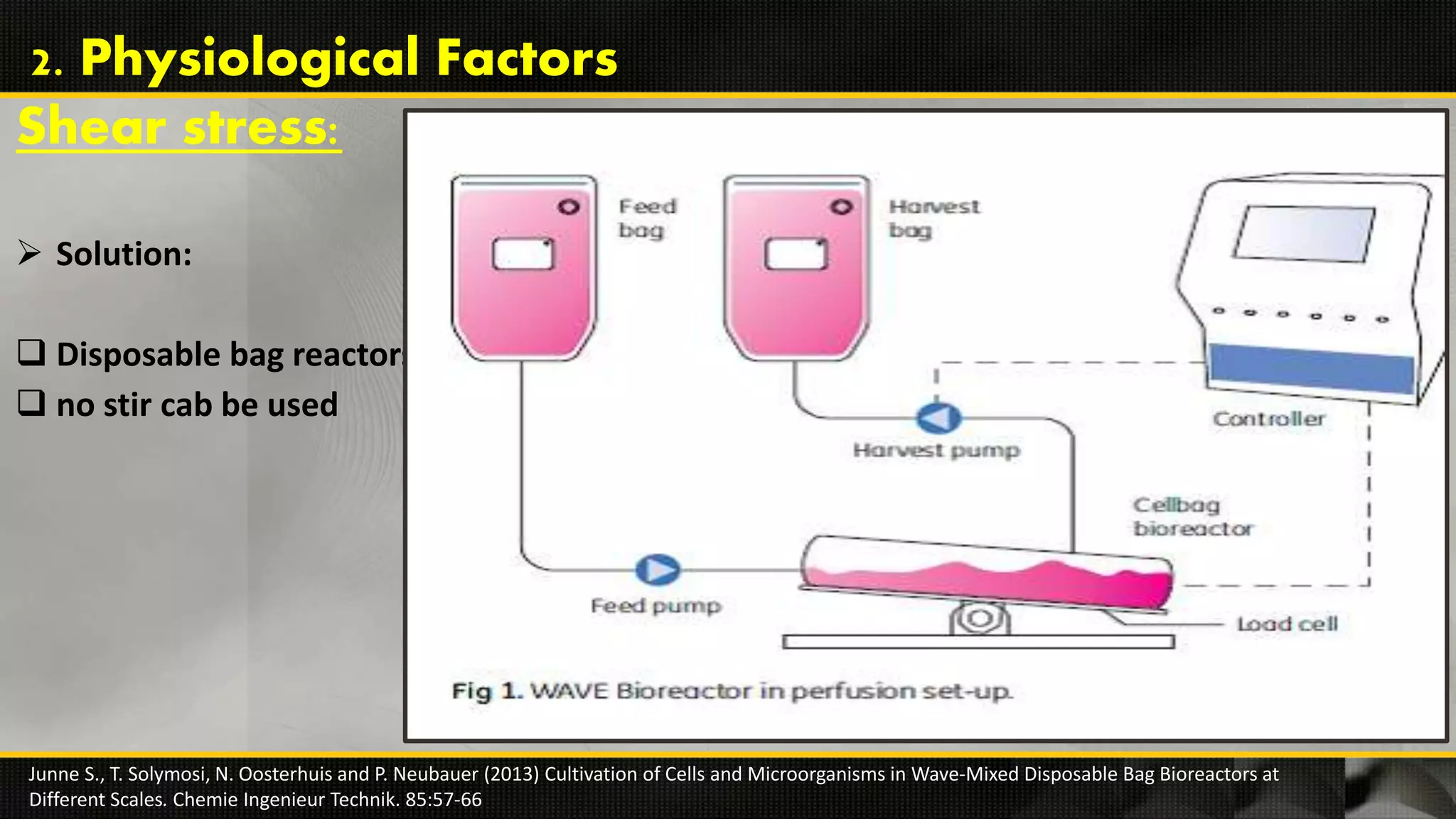

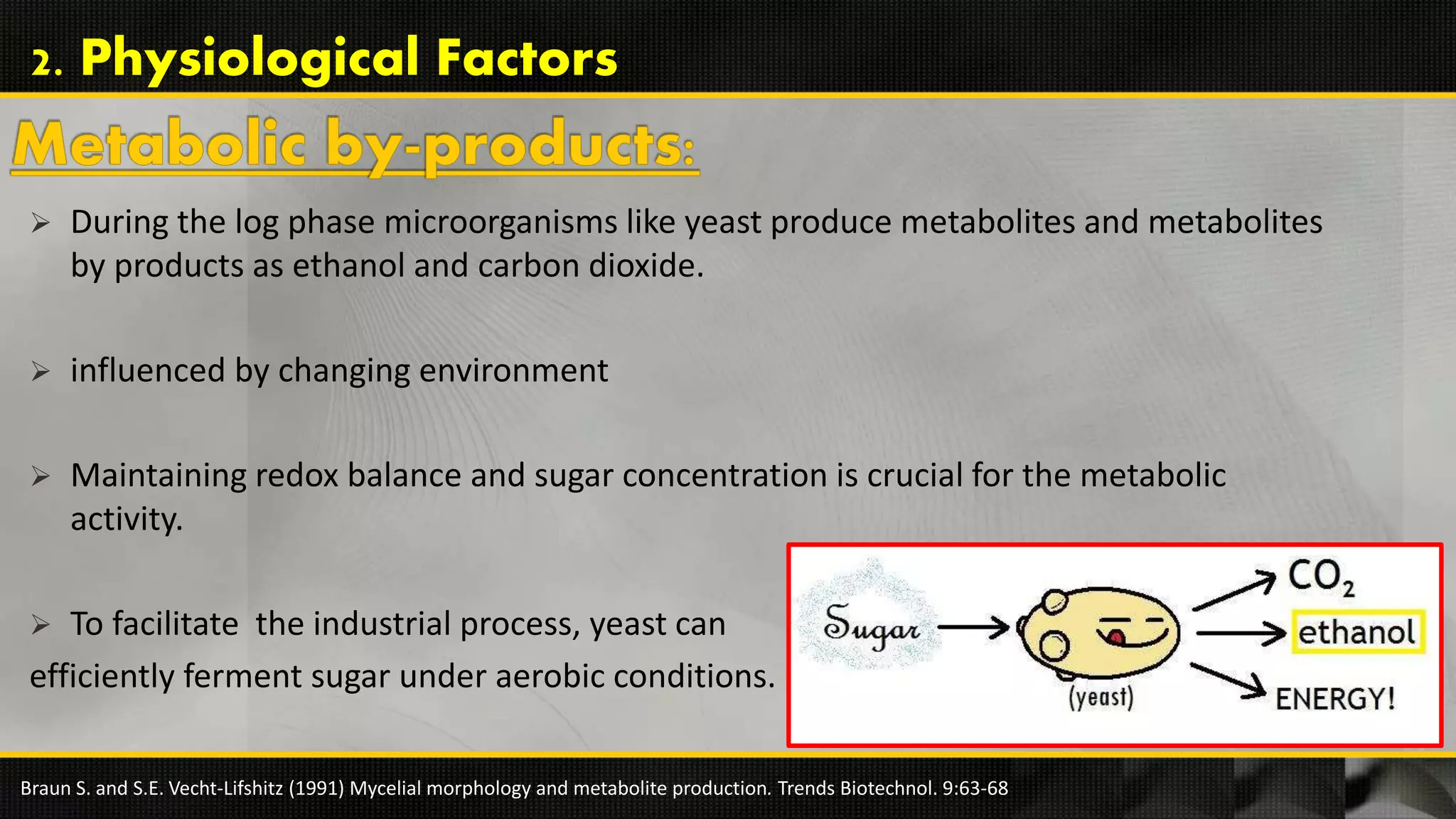

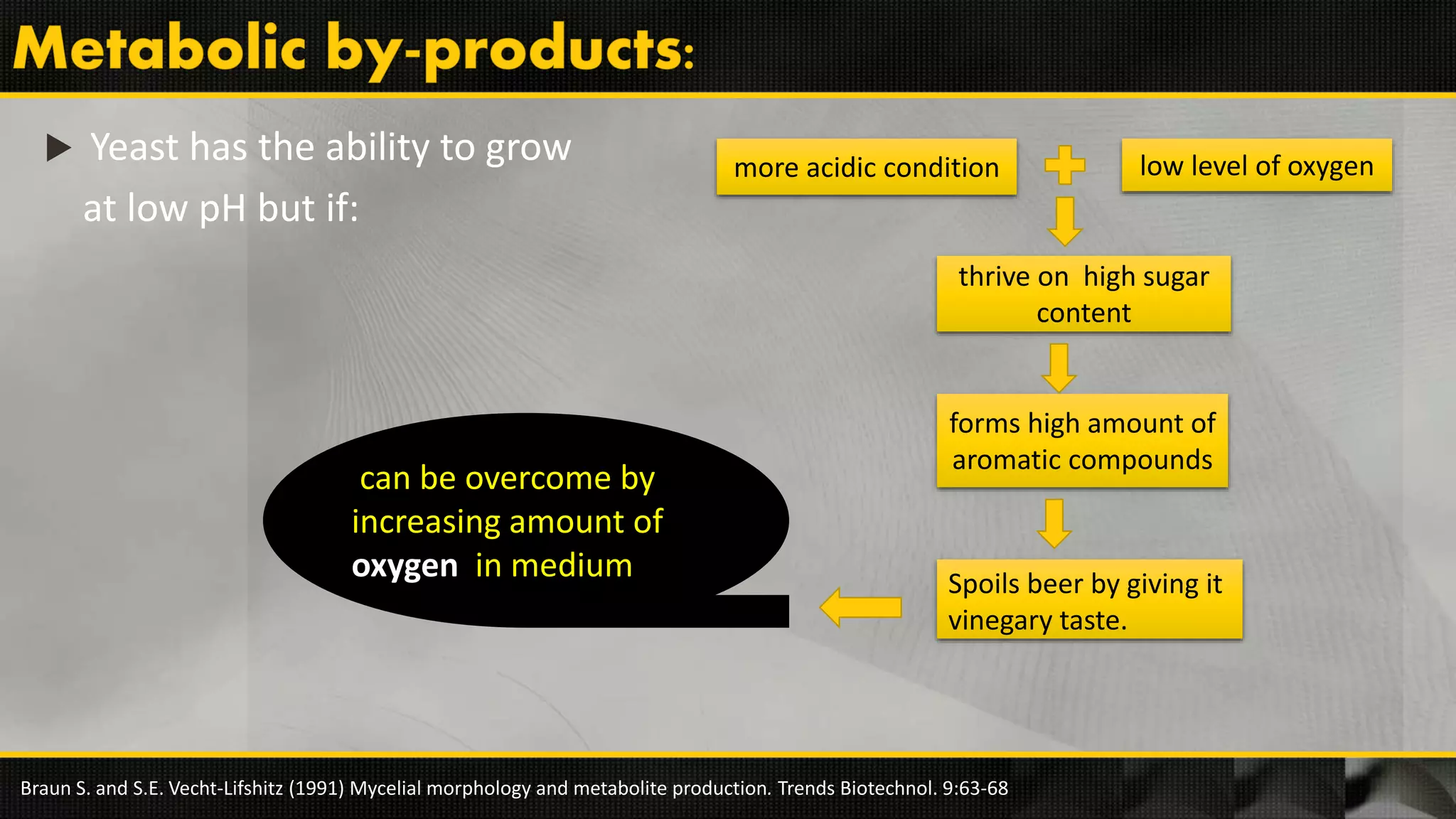

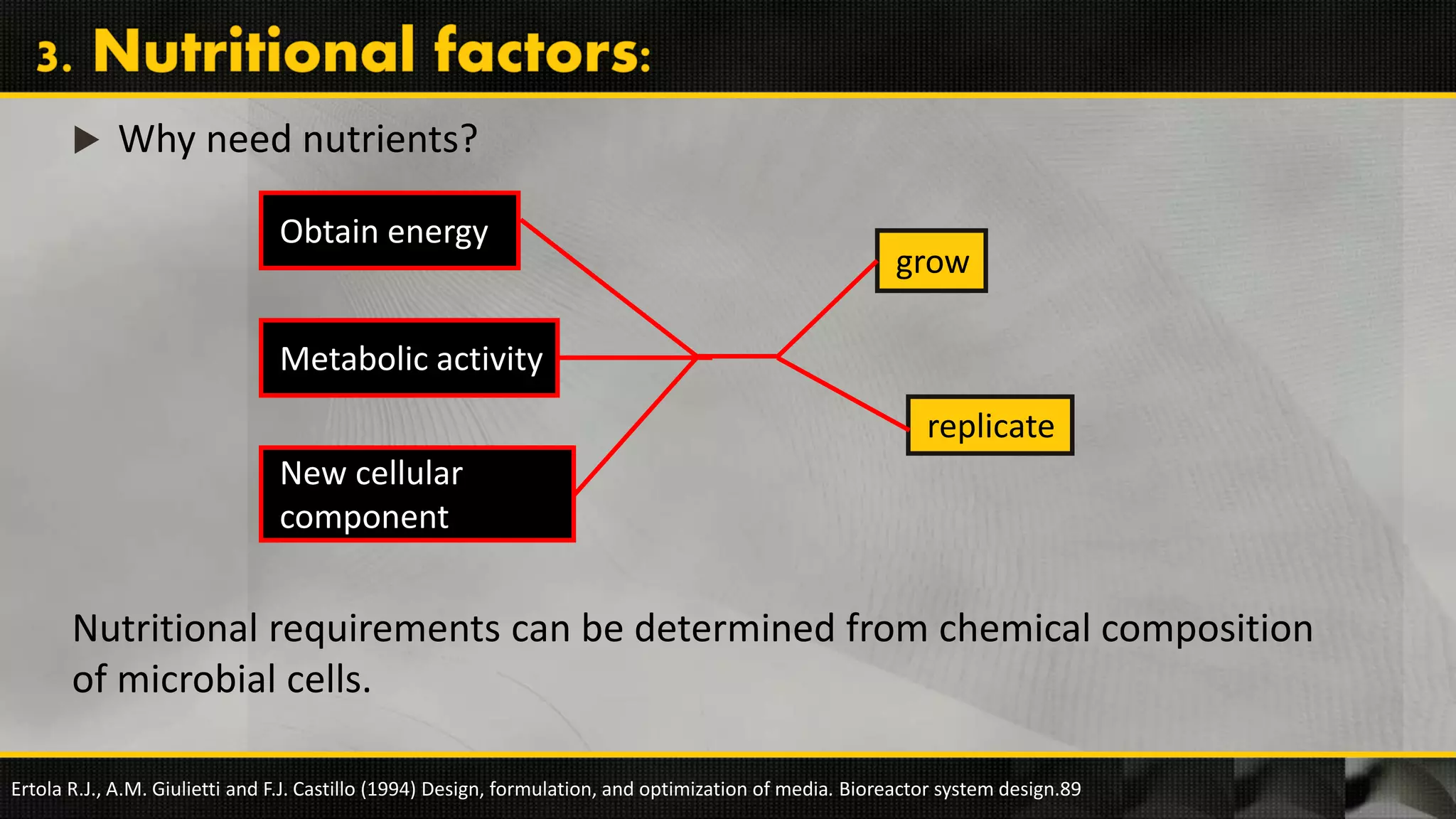

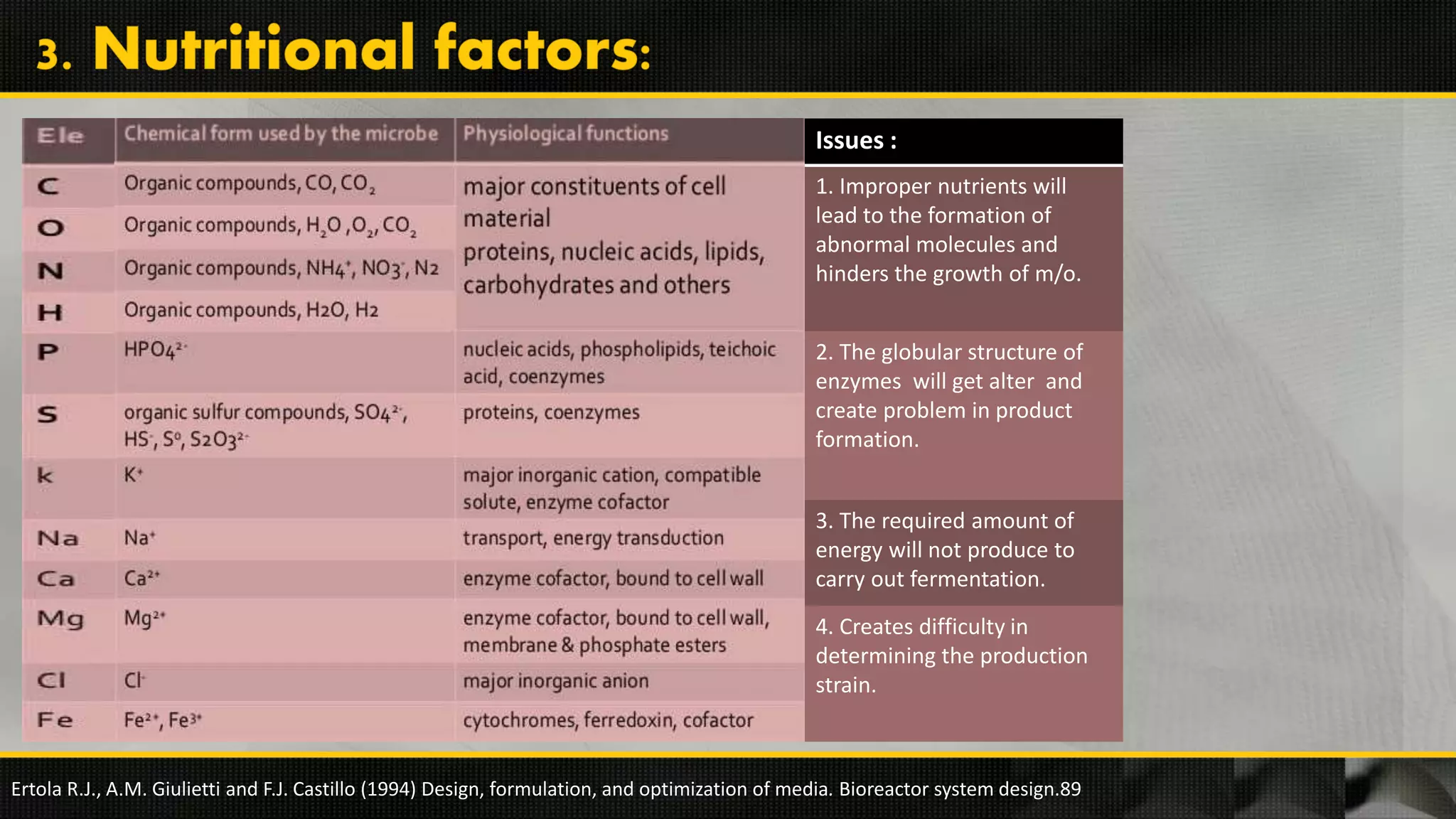

2. Physical factors like temperature, pH, viscosity, and shear stress can impact microbial growth and morphology. Nutritional factors must be optimized to support microbial metabolism and replication. Physiological changes in morphology, genetic stability, and metabolic byproducts can also affect product yield.

3. Careful control and optimization of all factors is needed to establish robust production strains and bioprocesses for microorganisms to efficiently produce desired products.