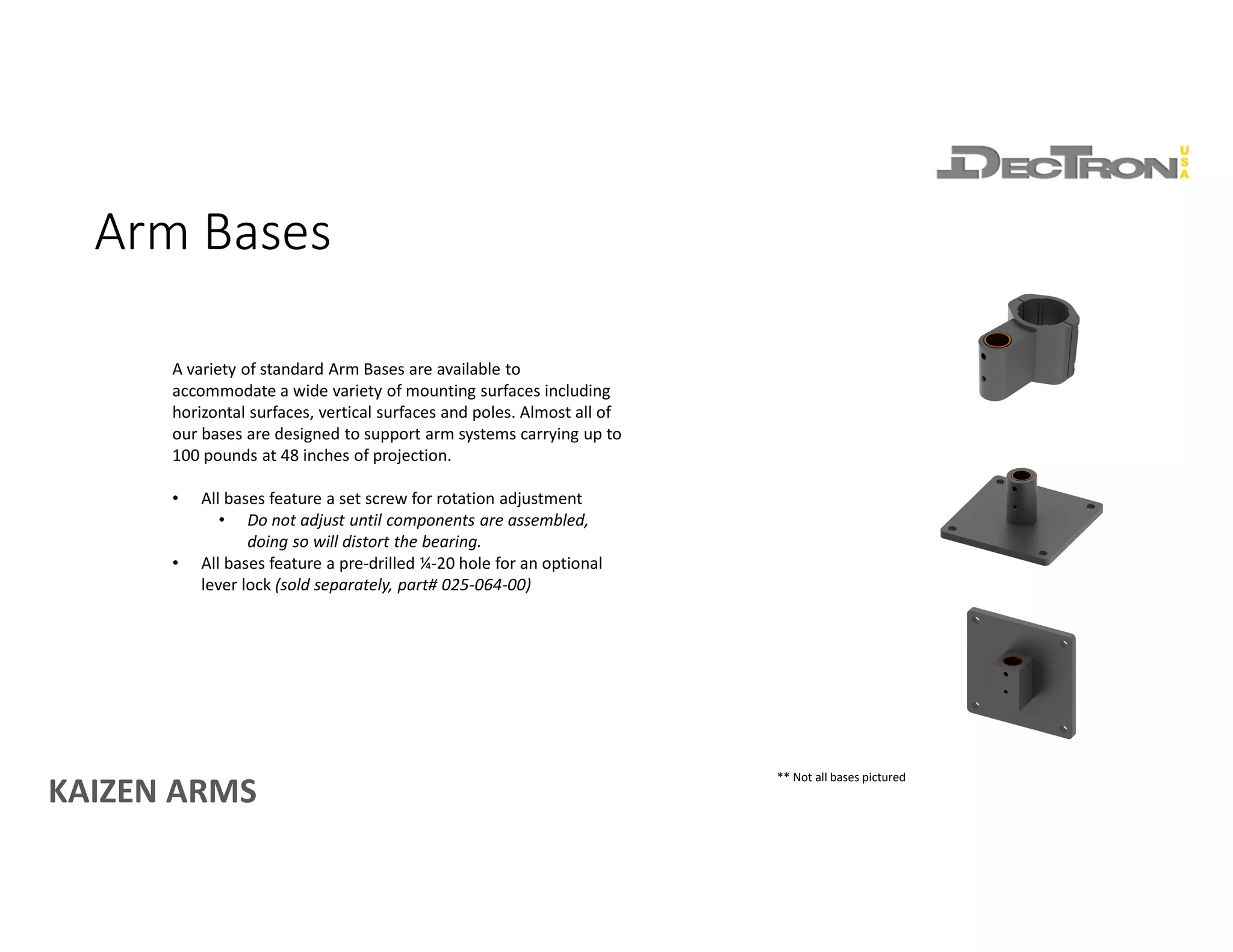

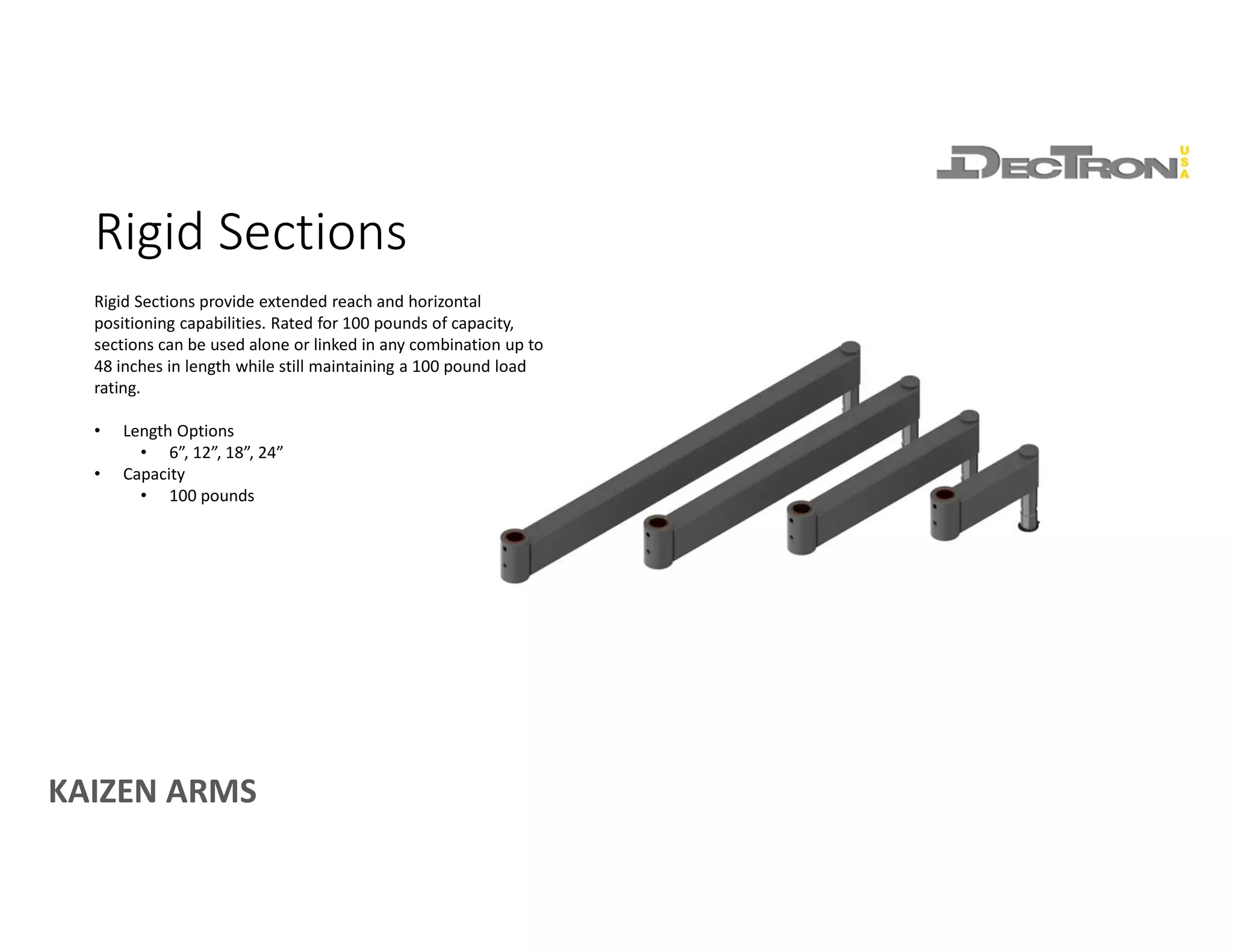

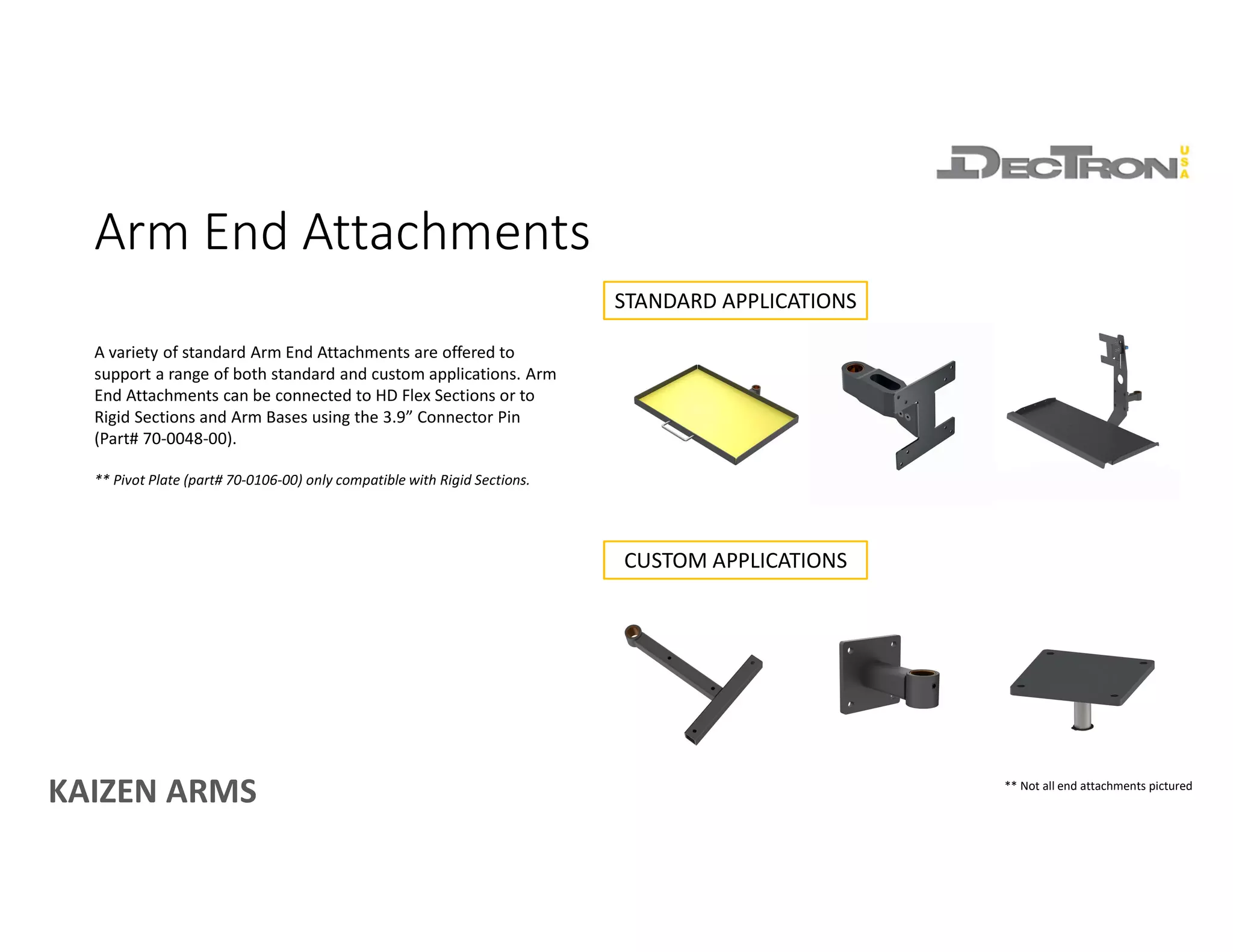

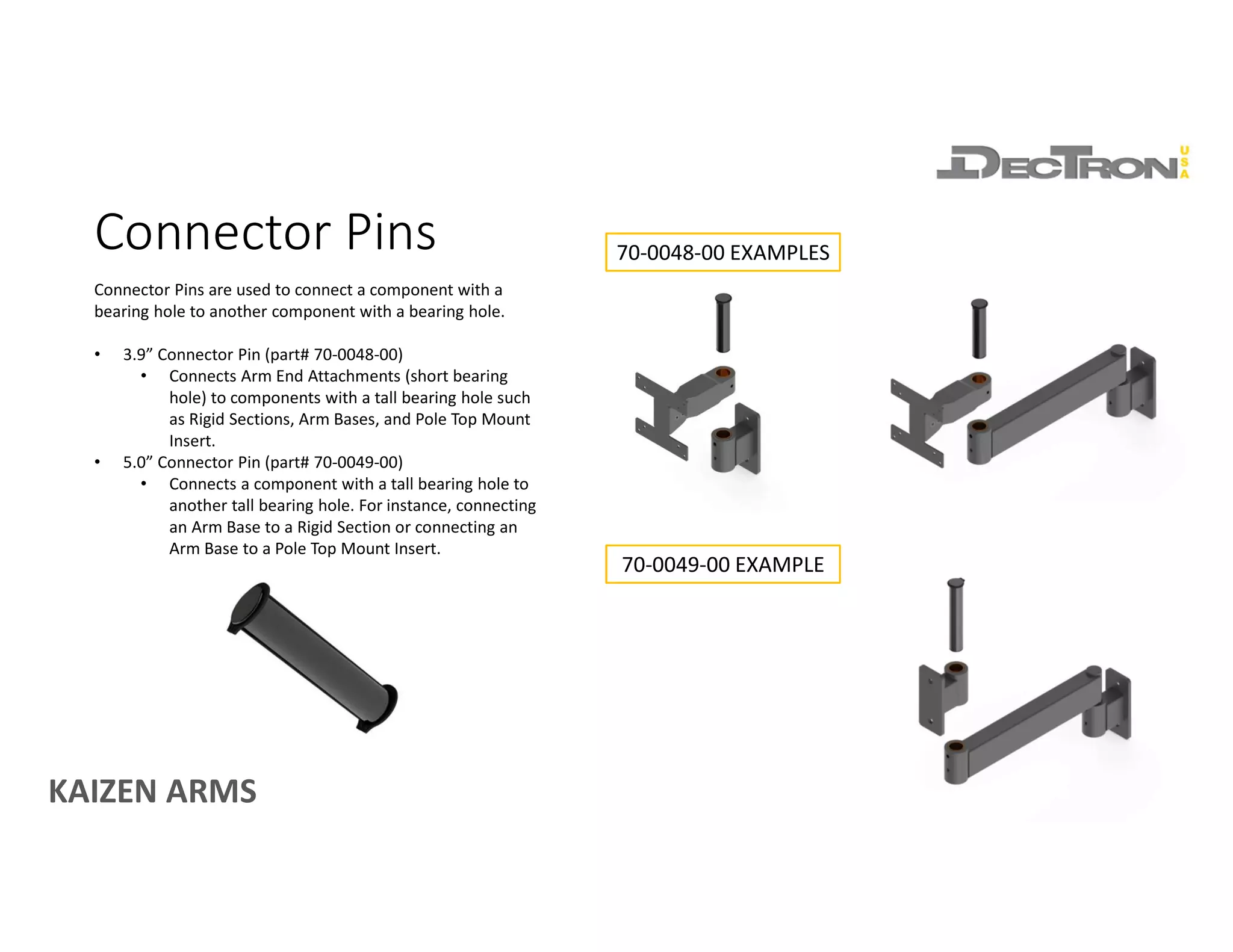

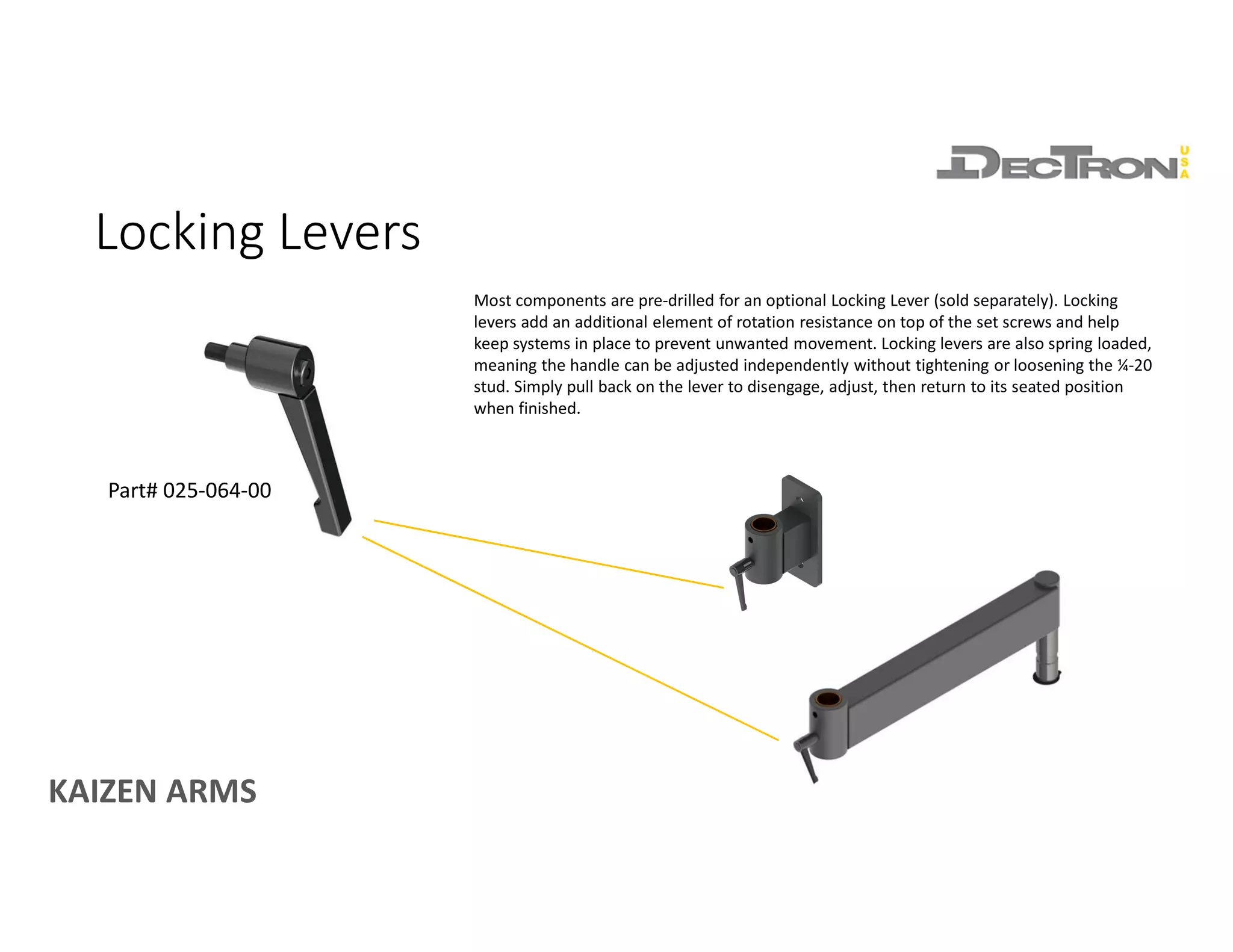

This document introduces the components and features of Kaizen Arms modular ergonomic arm systems manufactured by Dectron. It describes the various arm bases, rigid sections, flexible sections, end attachments, connectors, accessories, poles, and brackets that make up the system. It also provides instructions for assembling, adjusting, and securing the arm components and examples of potential arm configurations.