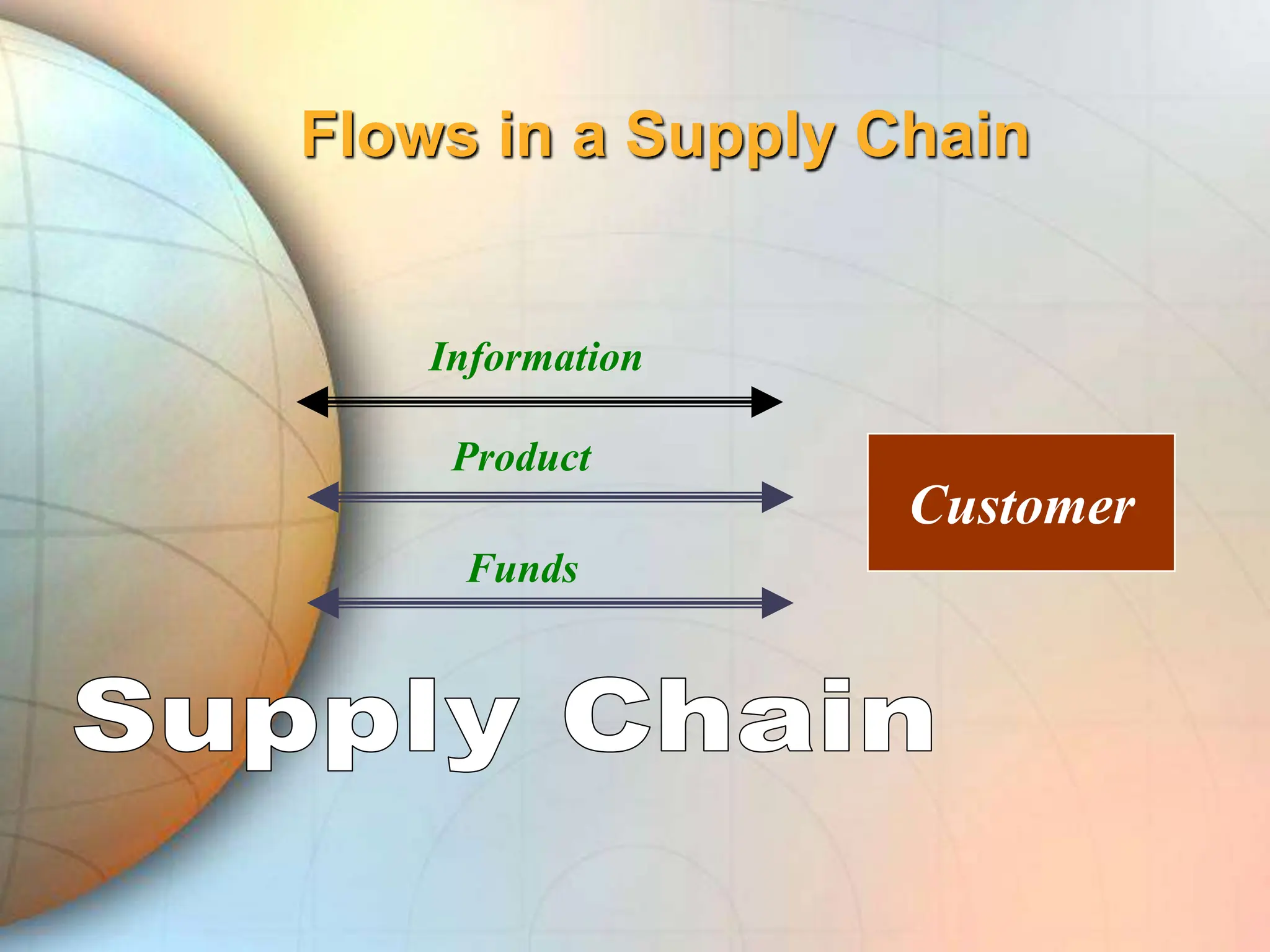

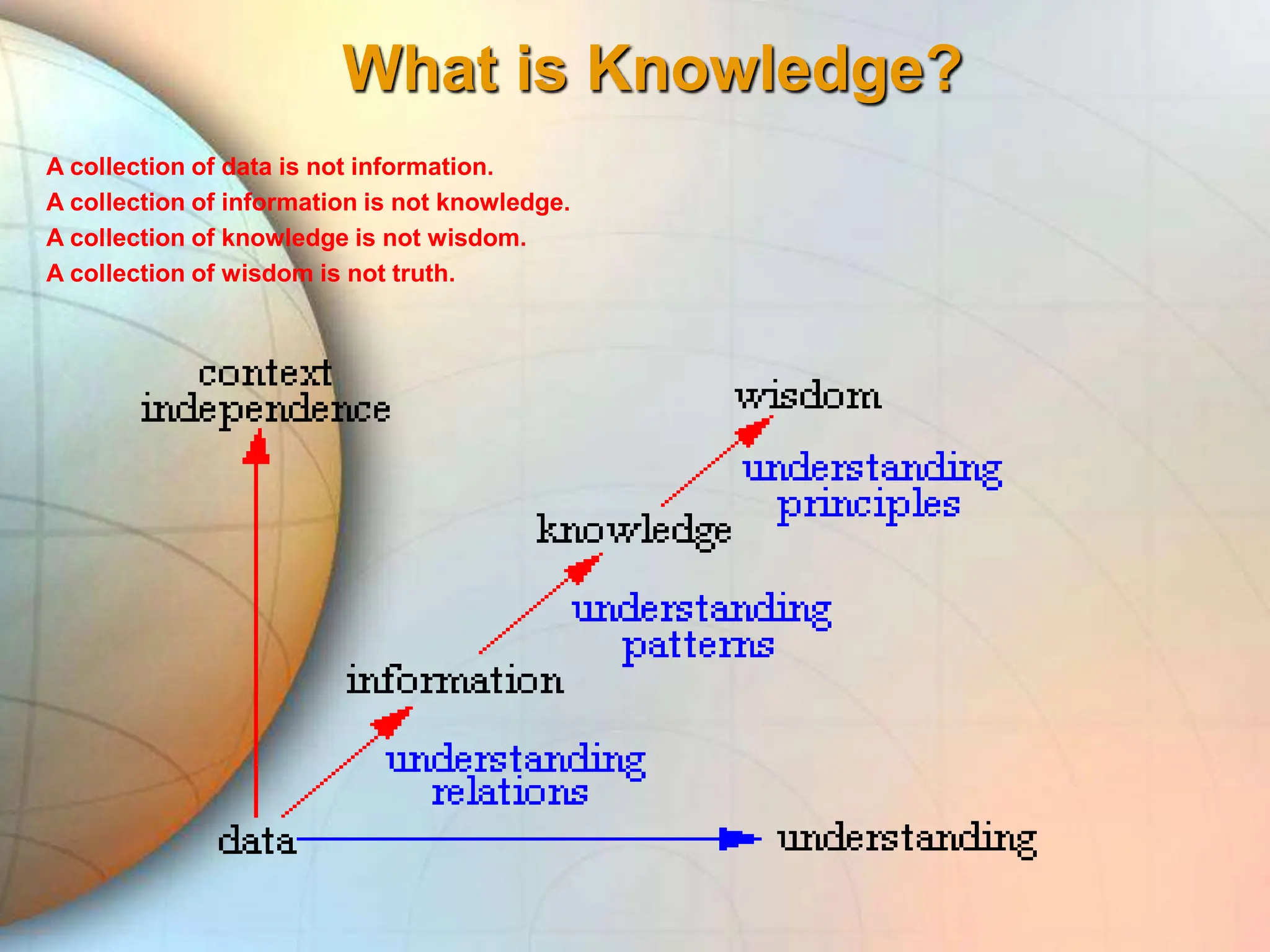

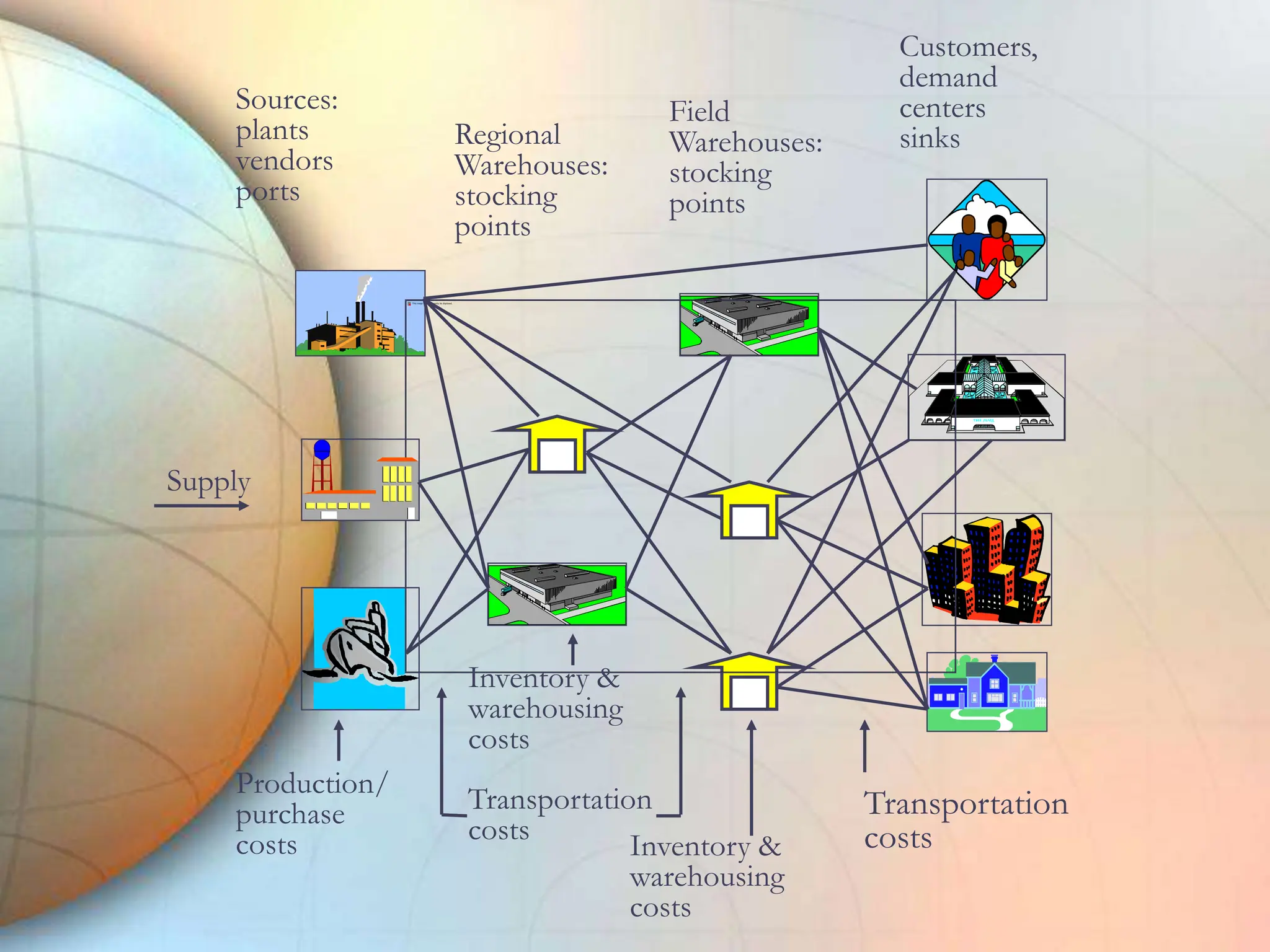

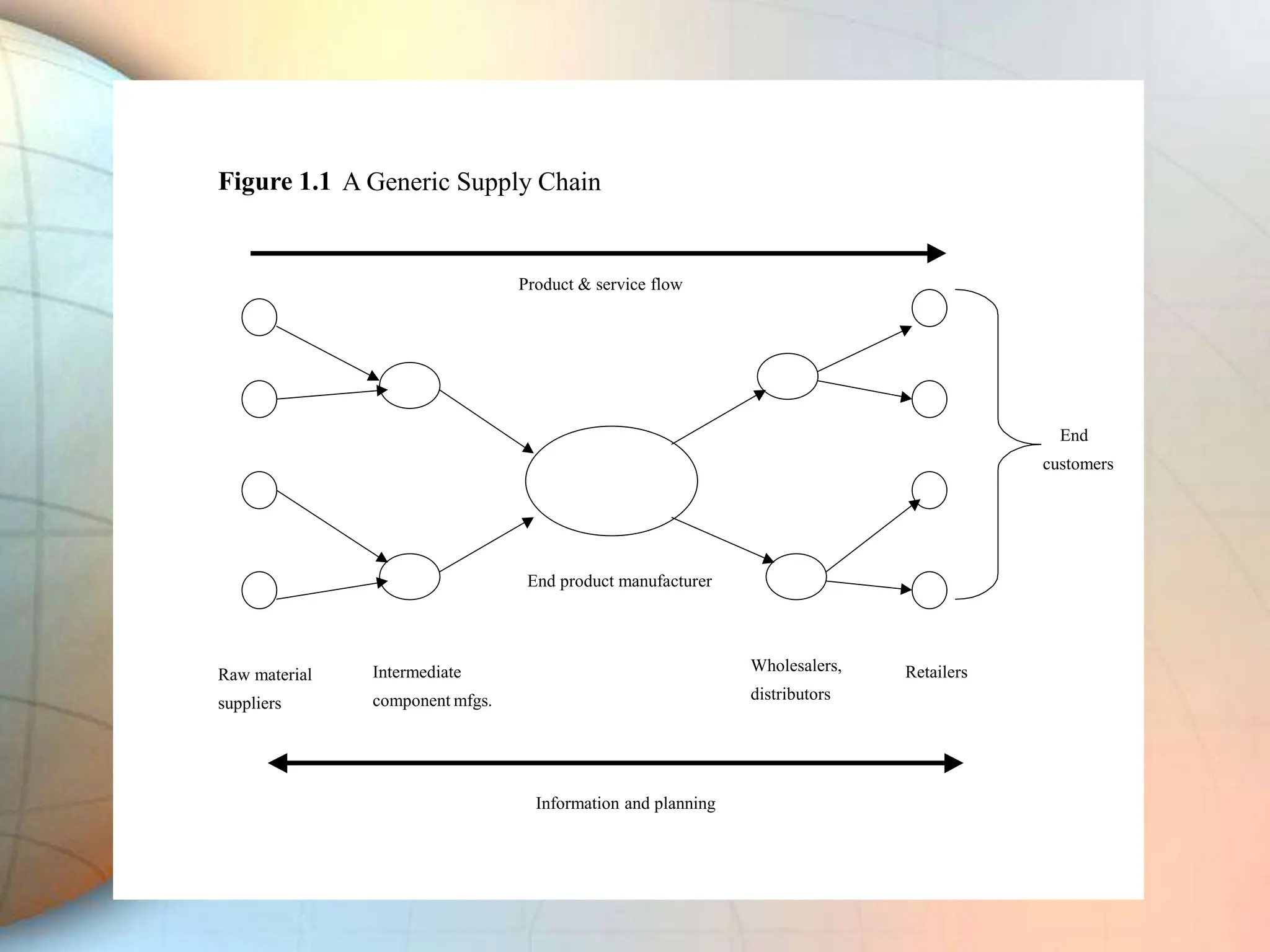

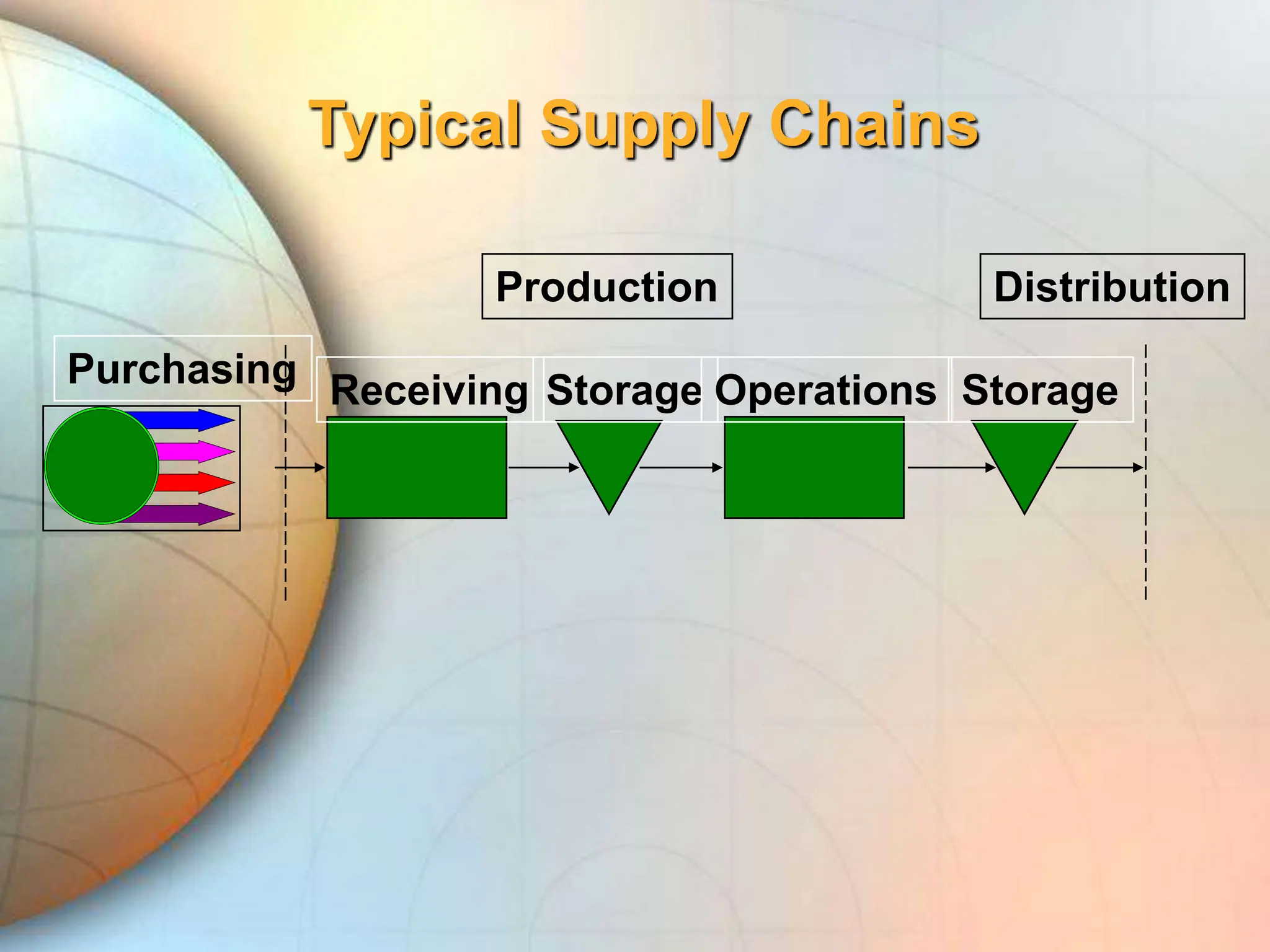

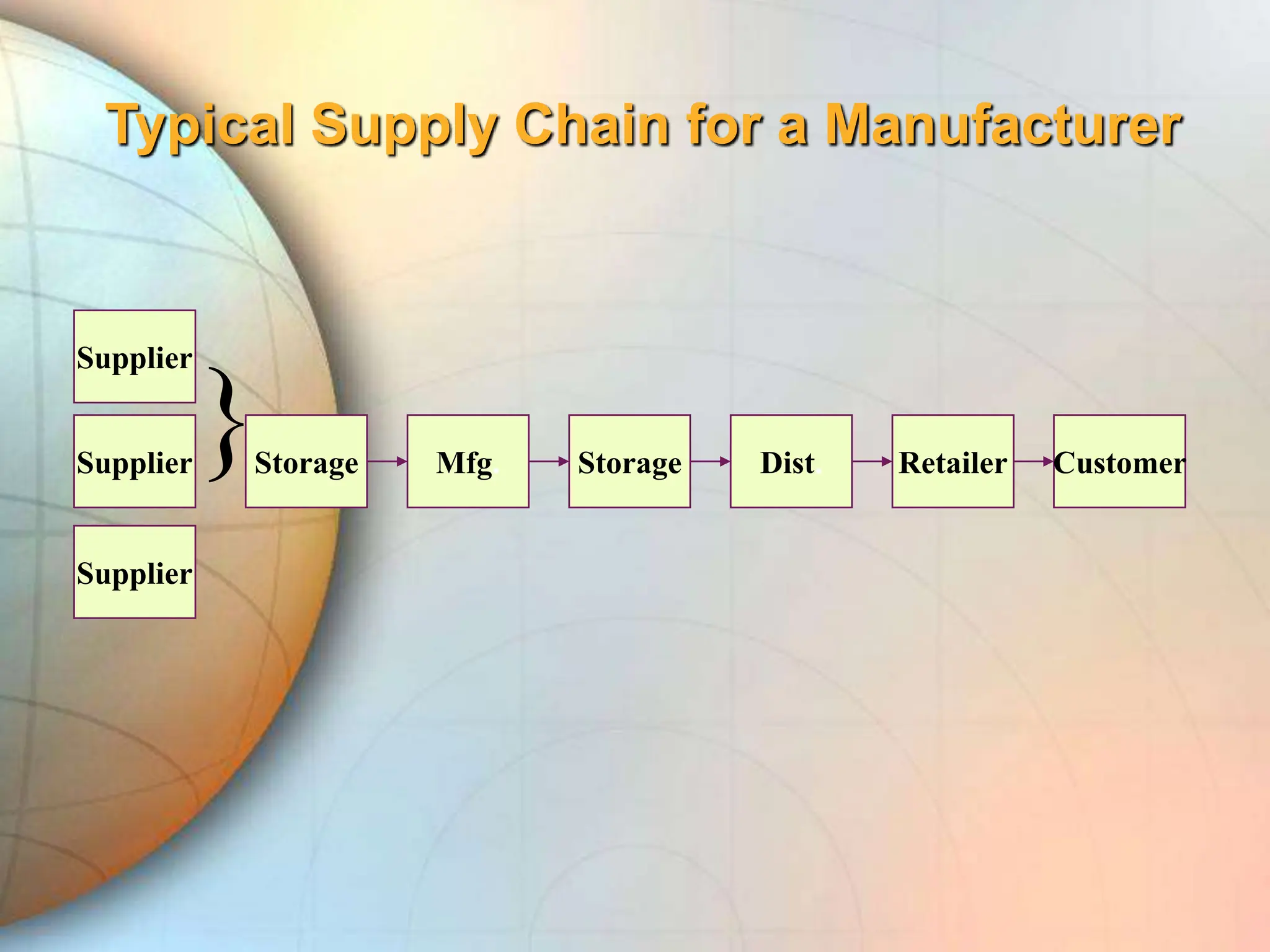

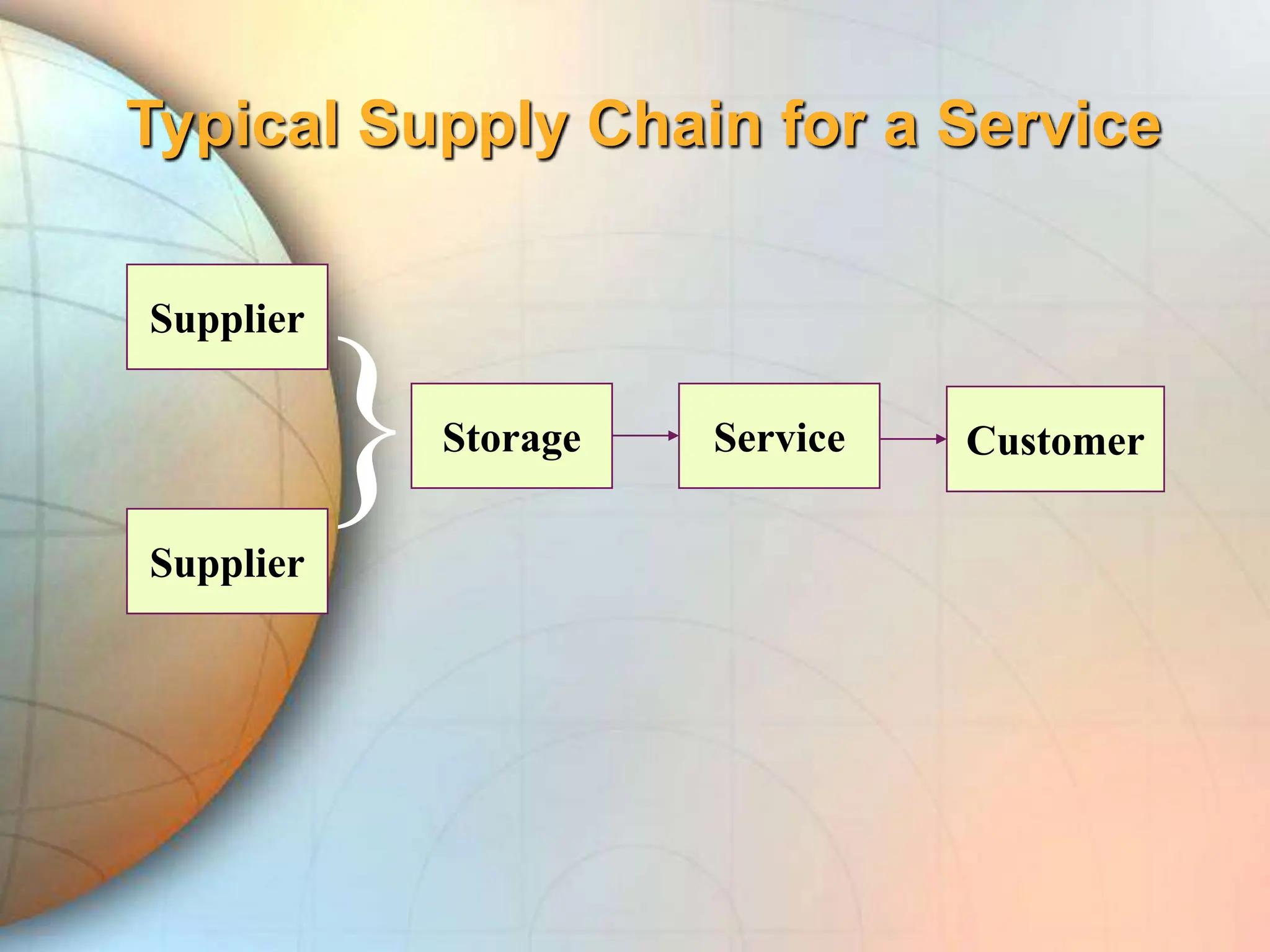

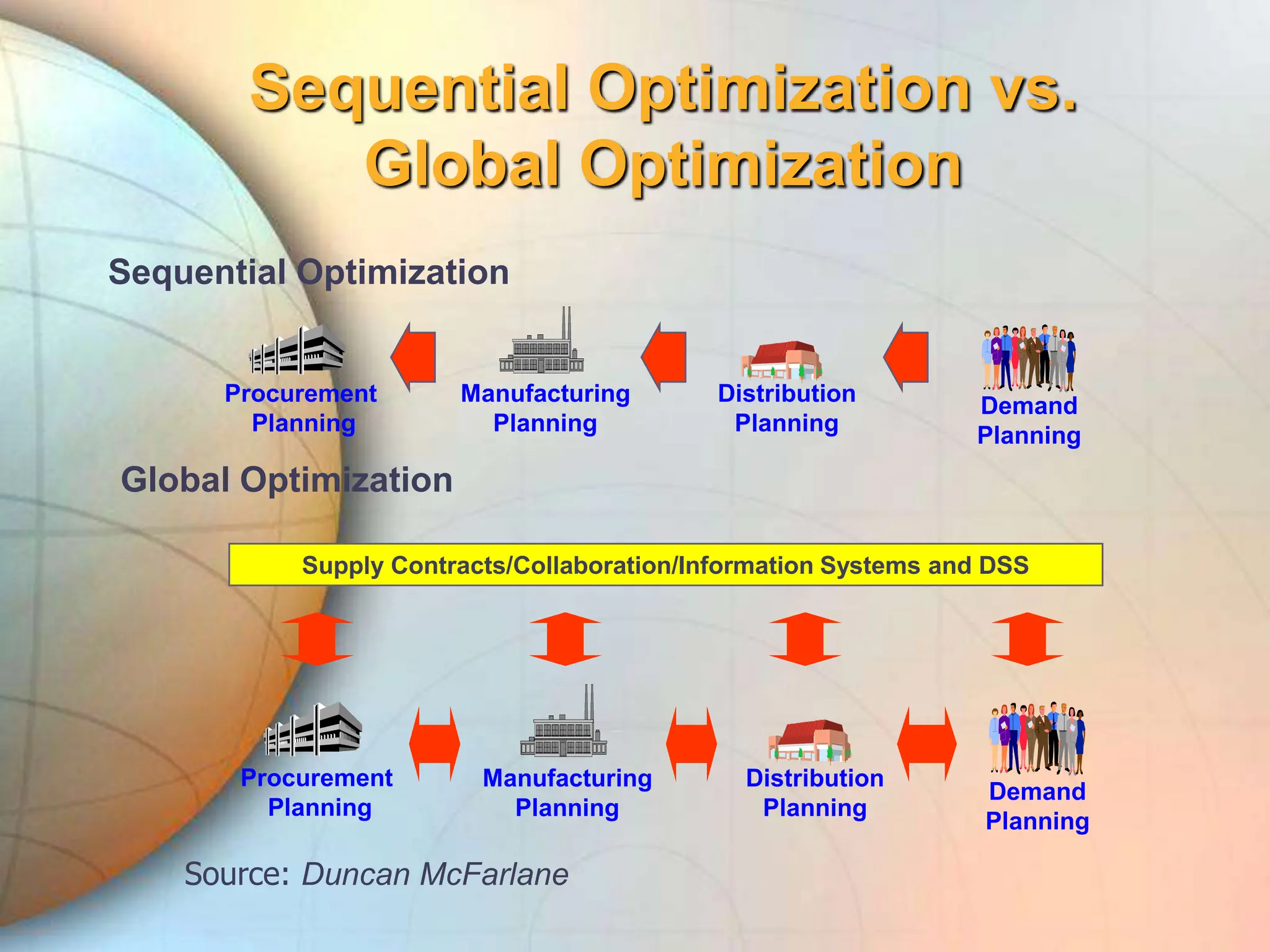

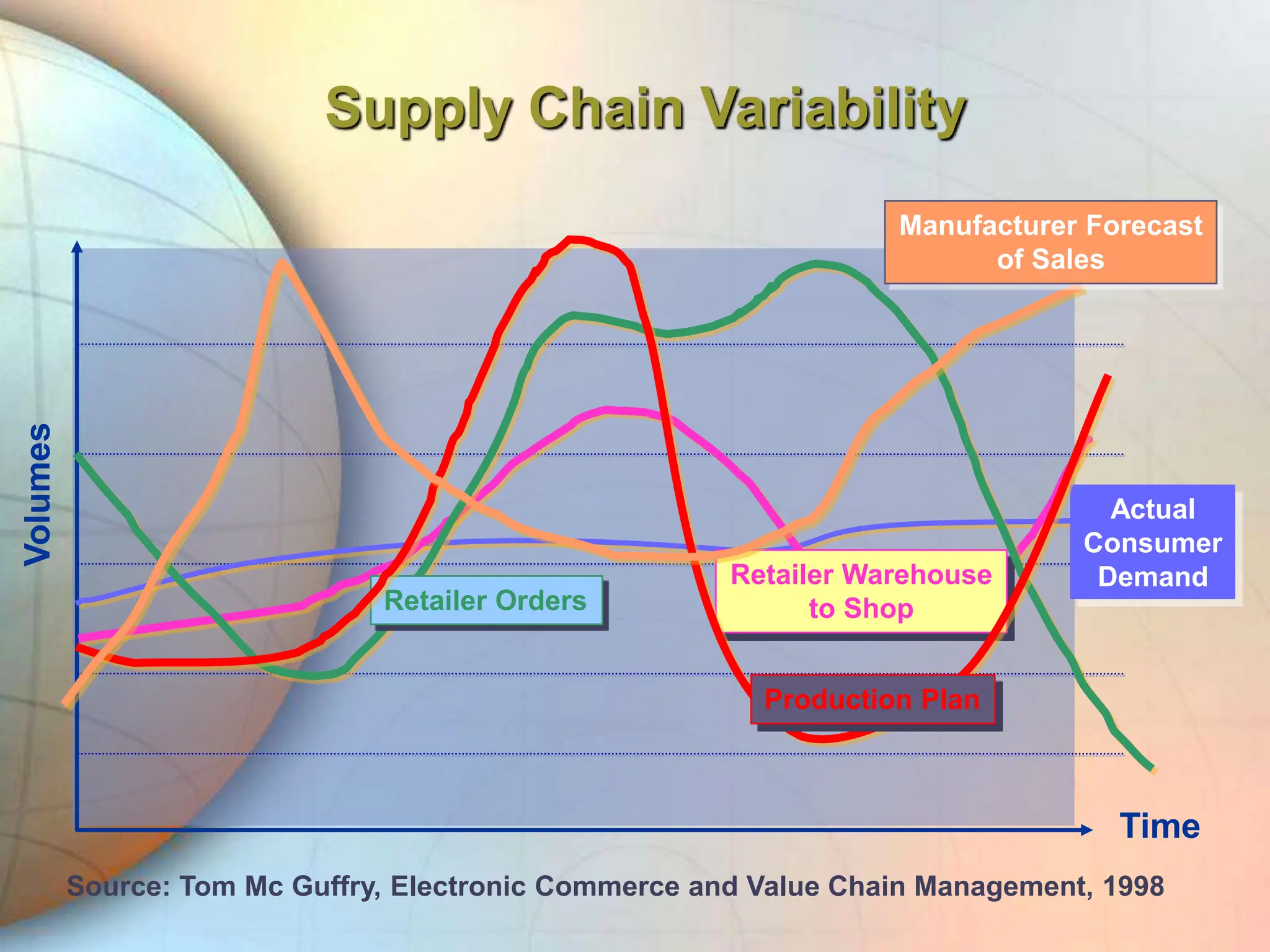

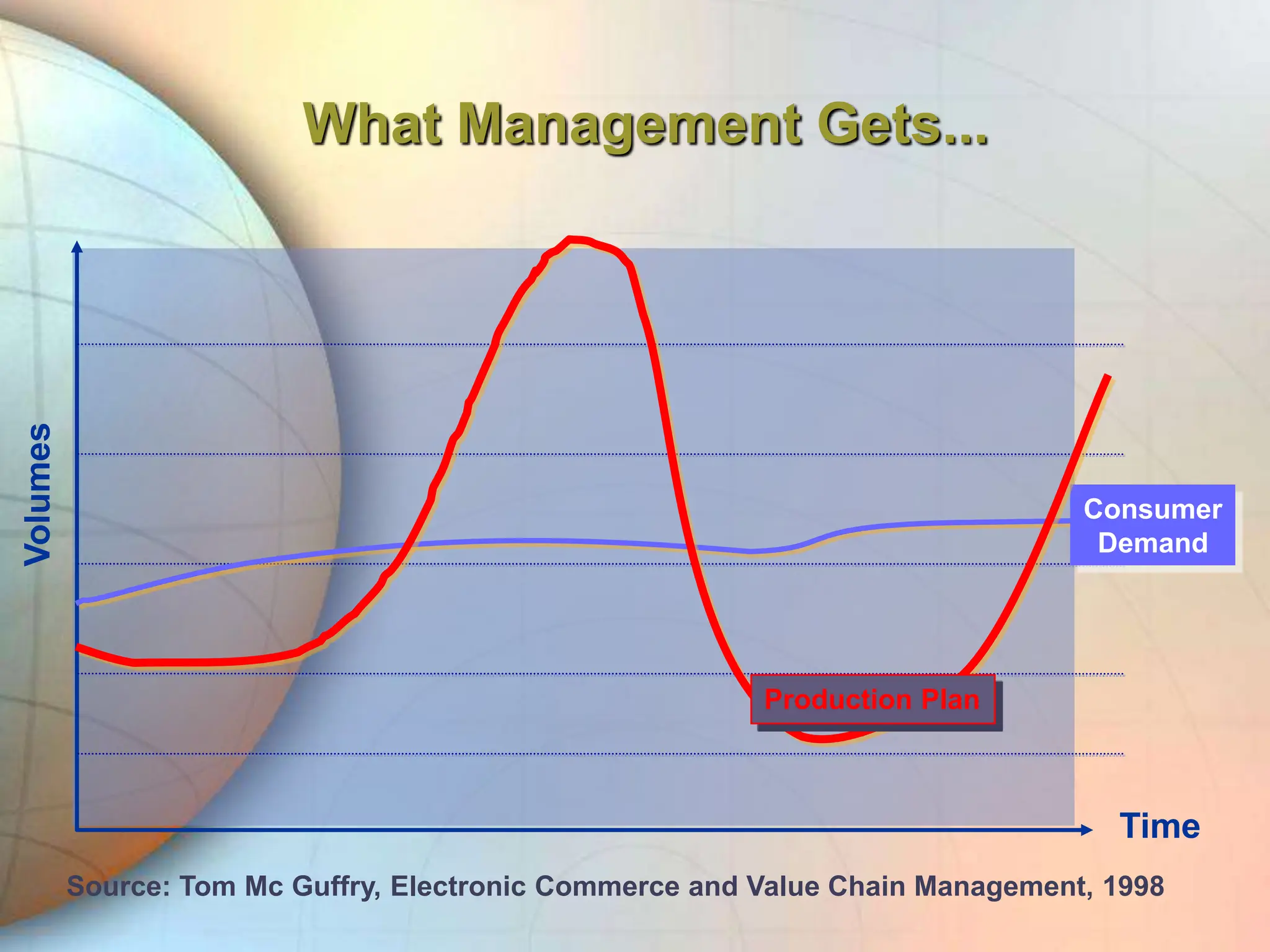

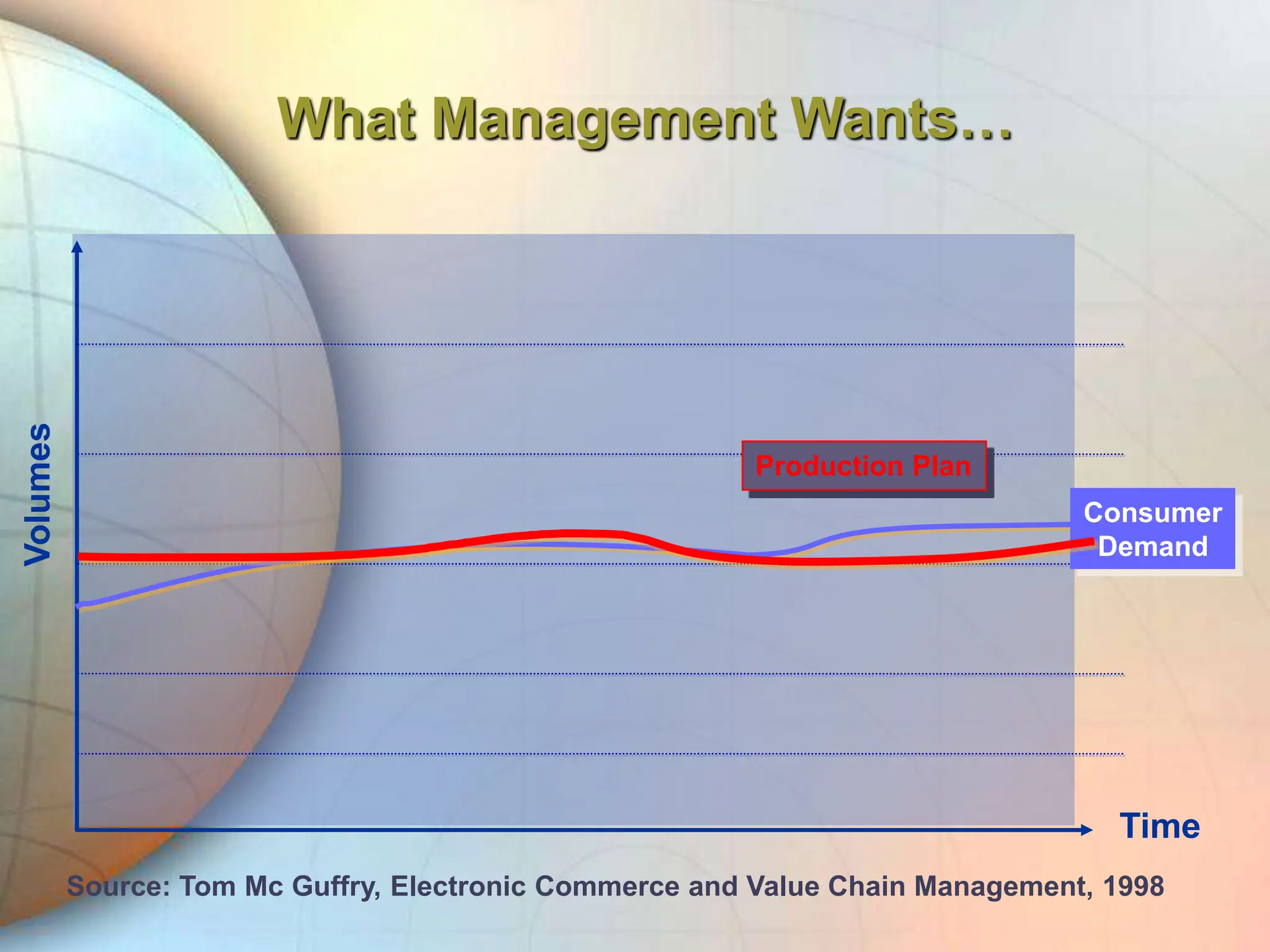

The document provides an extensive overview of supply chain management (SCM), outlining its importance, goals, elements, strategies, and potential benefits for organizations. It highlights the evolution of supply chains, the definition of SCM, and the complexities and uncertainties within the supply chain, emphasizing the need for integration and optimization. Furthermore, it presents examples of companies that have significantly improved their operations through effective SCM practices and discusses the implications of global competition and technological advancements.