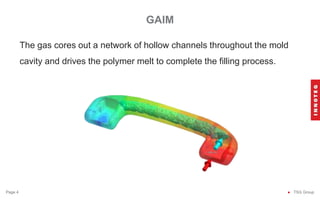

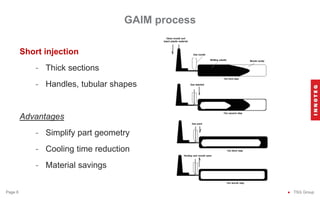

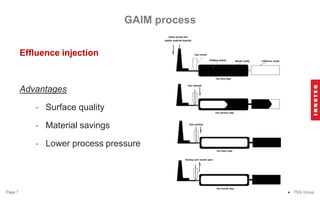

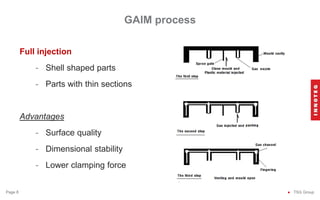

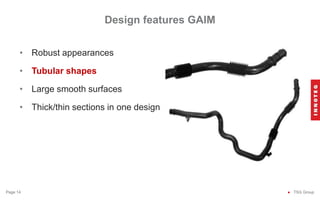

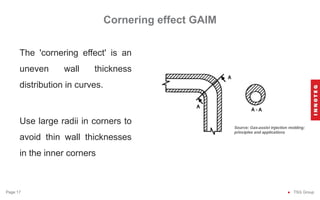

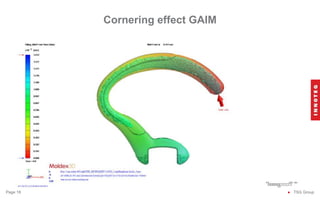

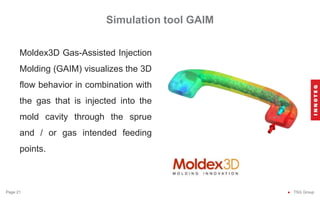

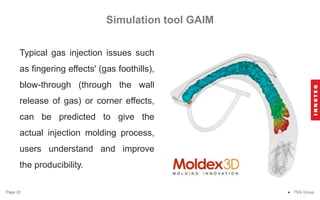

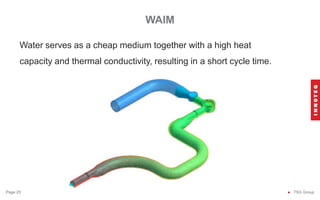

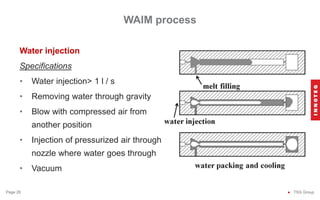

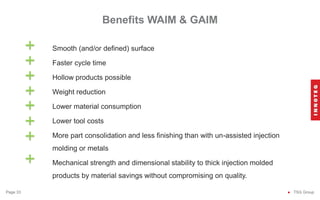

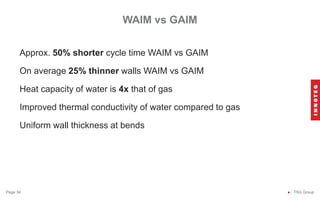

GAIM (Gas Assisted Injection Molding) and WAIM (Water Assisted Injection Molding) are advanced injection molding processes that use gas or water to enhance the quality and efficiency of molding parts with varying geometries. GAIM helps create hollow channels, reduces cooling time, and saves materials, while WAIM offers similar benefits with potentially lower costs due to water being used as the medium. Both processes are beneficial for automotive and consumer products, although they come with respective challenges and developmental considerations.