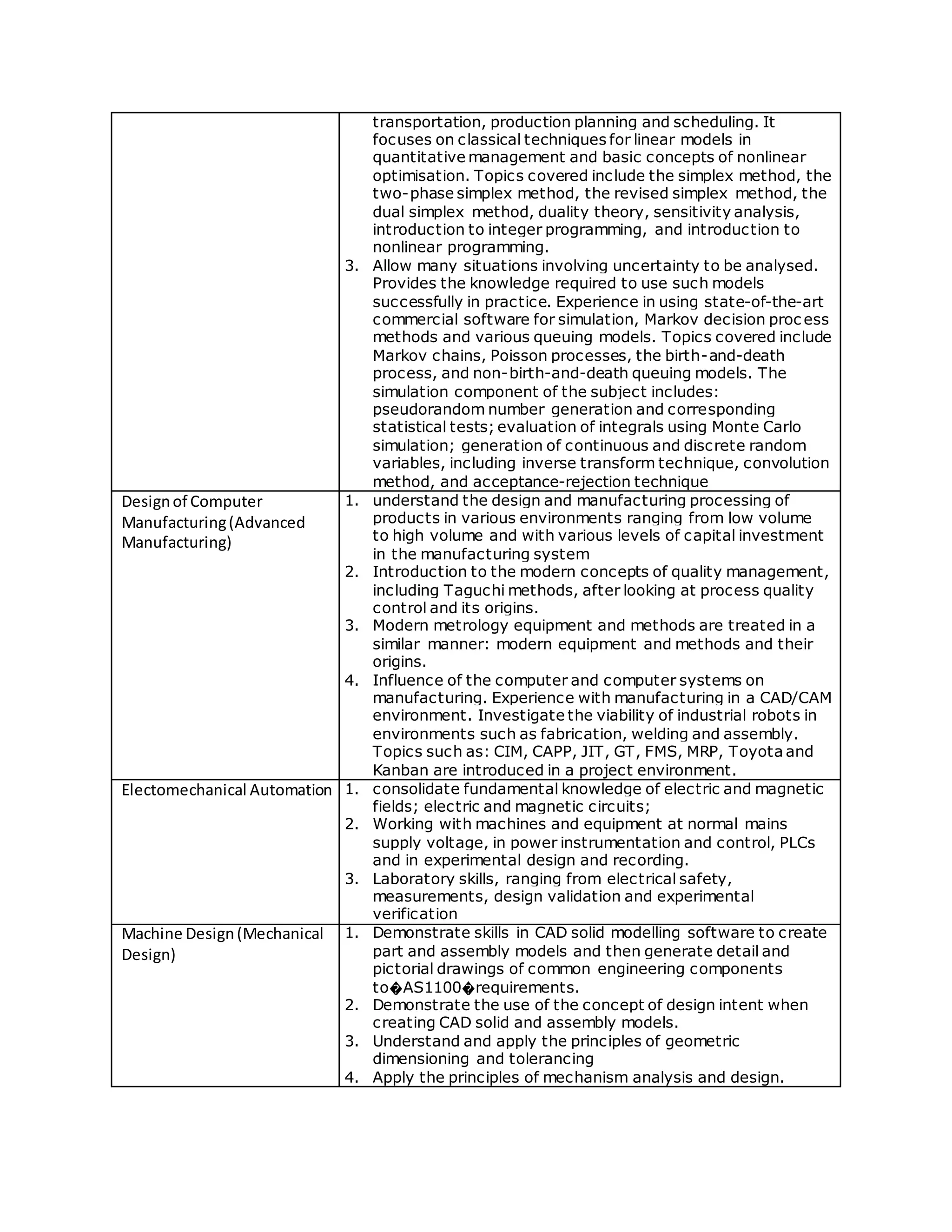

This document outlines the course descriptions and learning objectives for several industrial engineering subjects completed by the author between 2008-2012 at Applies Science University. The subjects include Engineering Material, Statics, Advanced Engineering Math, Strength in Materials, Probability and Statics, Fluid Mechanics, Manufacturing Processes, Operations Research, Design of Computer Manufacturing, Electromechanical Automation, Machine Design, and Projects Management. The subjects cover topics such as stress analysis, material properties, applied mathematics, manufacturing processes, quality control, and project management.