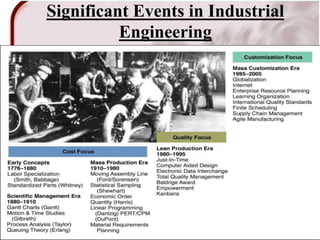

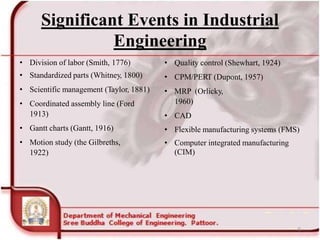

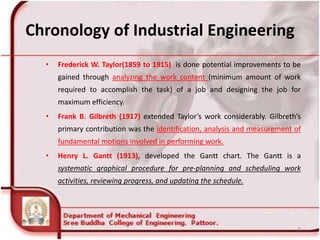

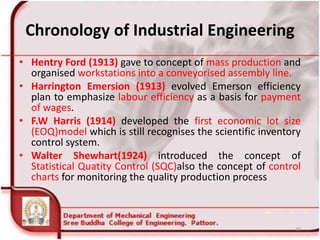

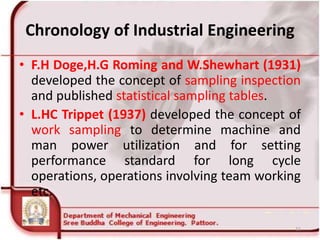

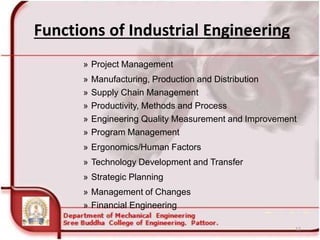

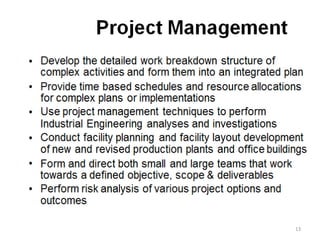

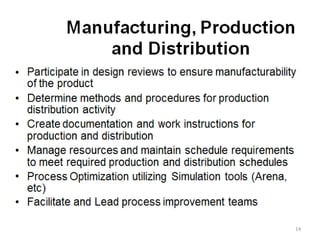

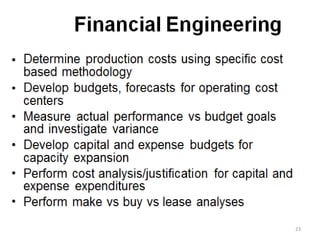

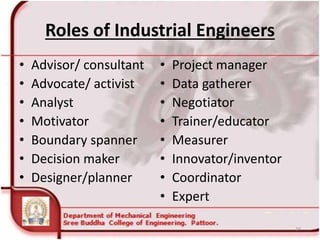

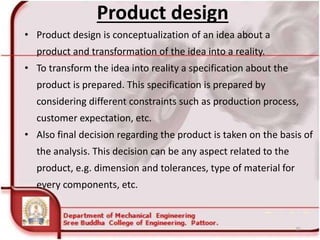

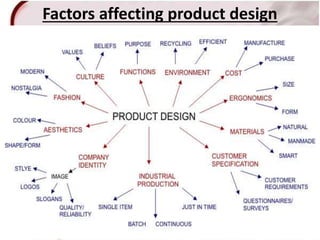

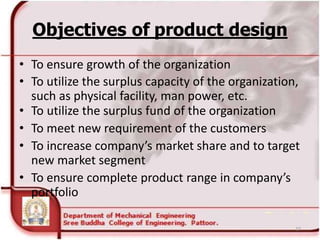

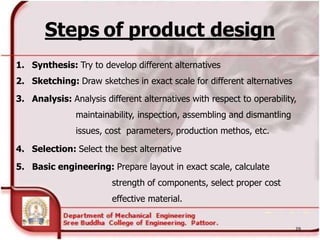

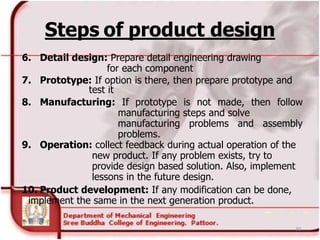

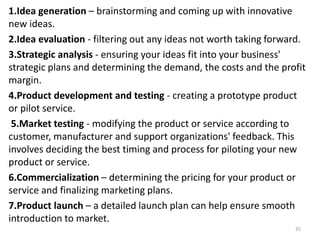

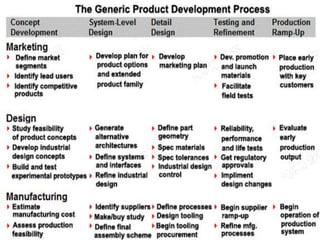

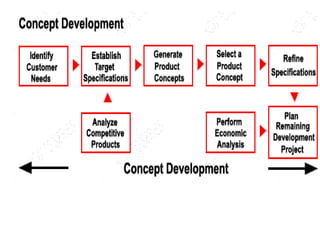

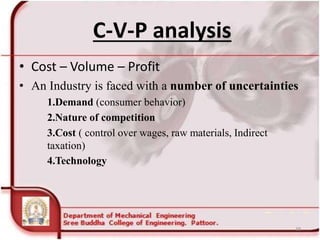

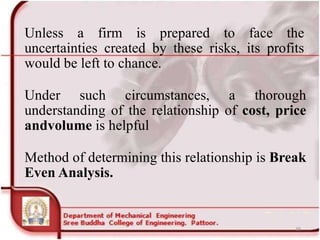

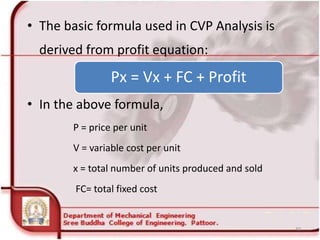

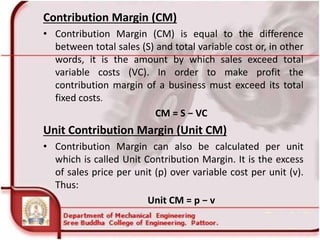

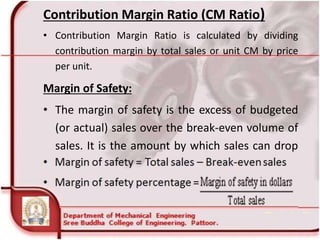

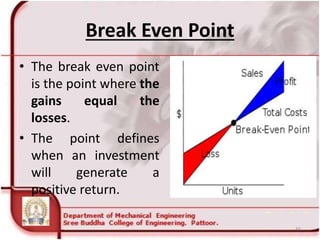

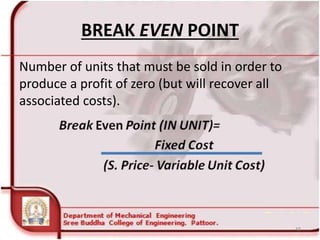

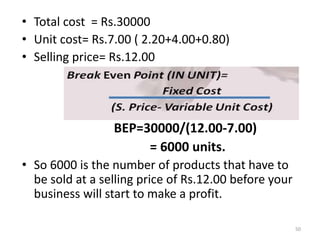

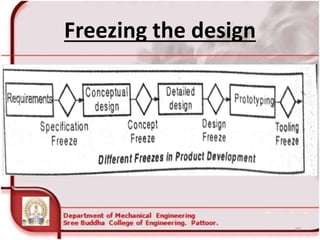

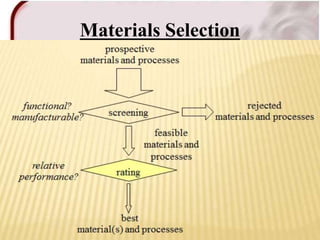

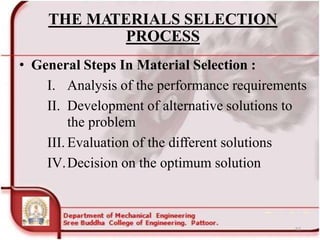

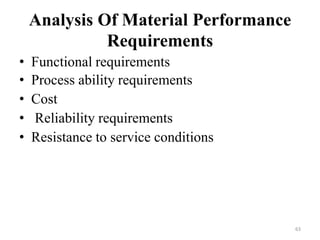

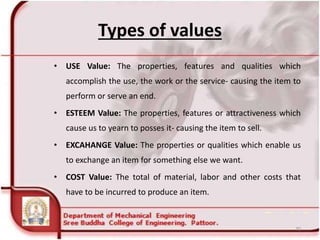

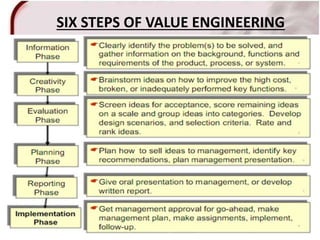

The document provides an overview of industrial engineering, detailing its history, significant milestones, and the roles of industrial engineers in various functions like project management and product design. It outlines key concepts such as cost-volume-profit analysis and break-even analysis, as well as methodologies for product design and prototyping. Additionally, the document discusses value engineering principles aimed at optimizing product functions at minimal costs while maintaining quality and reliability.