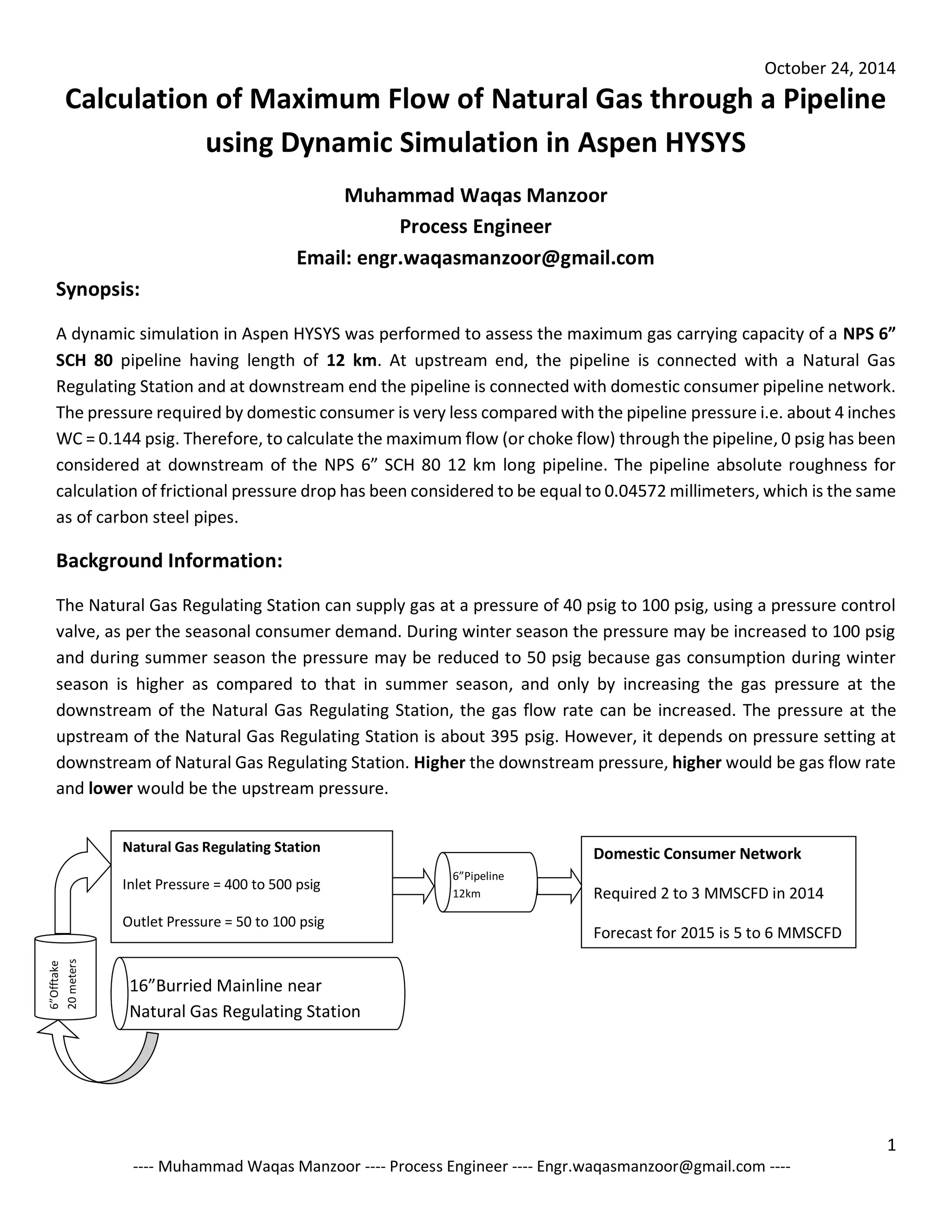

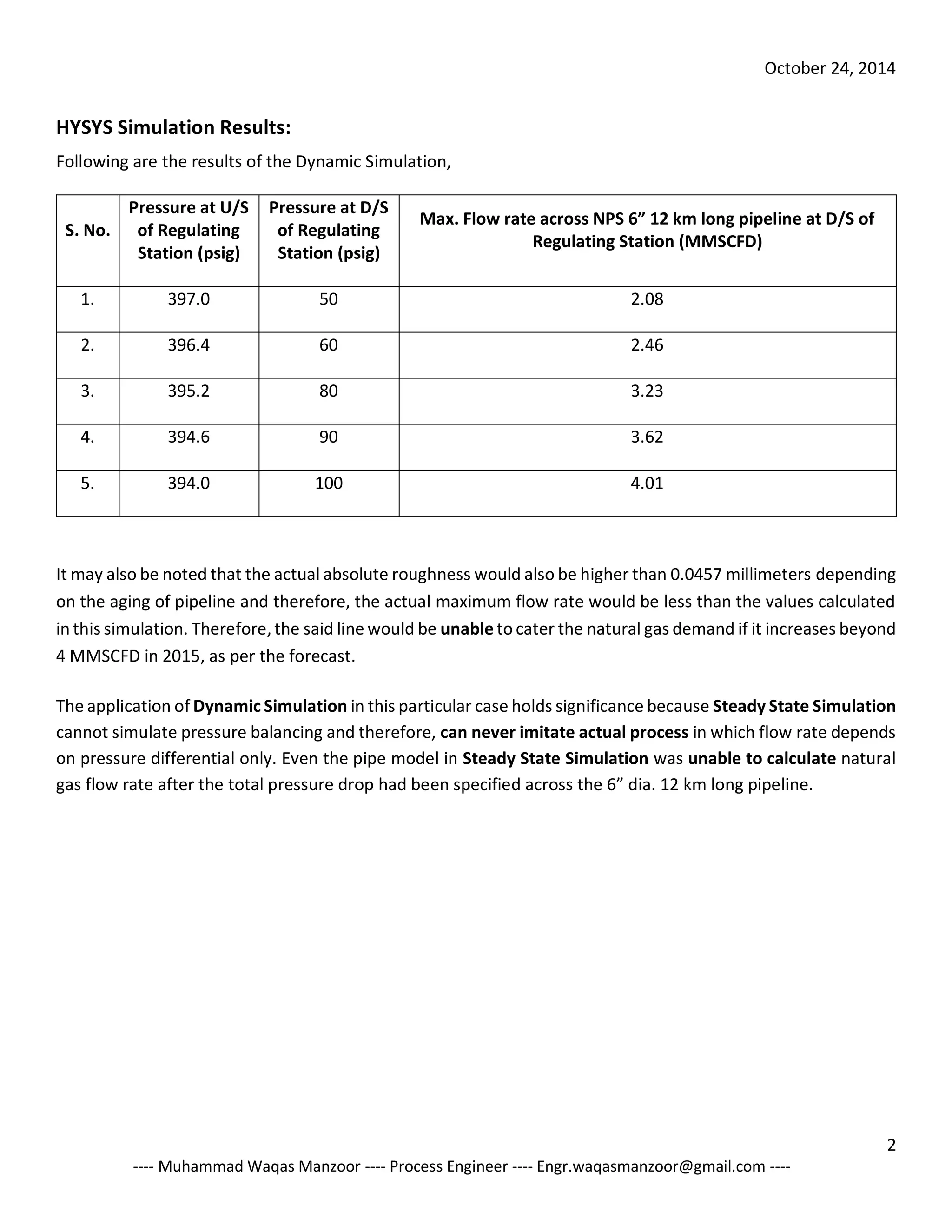

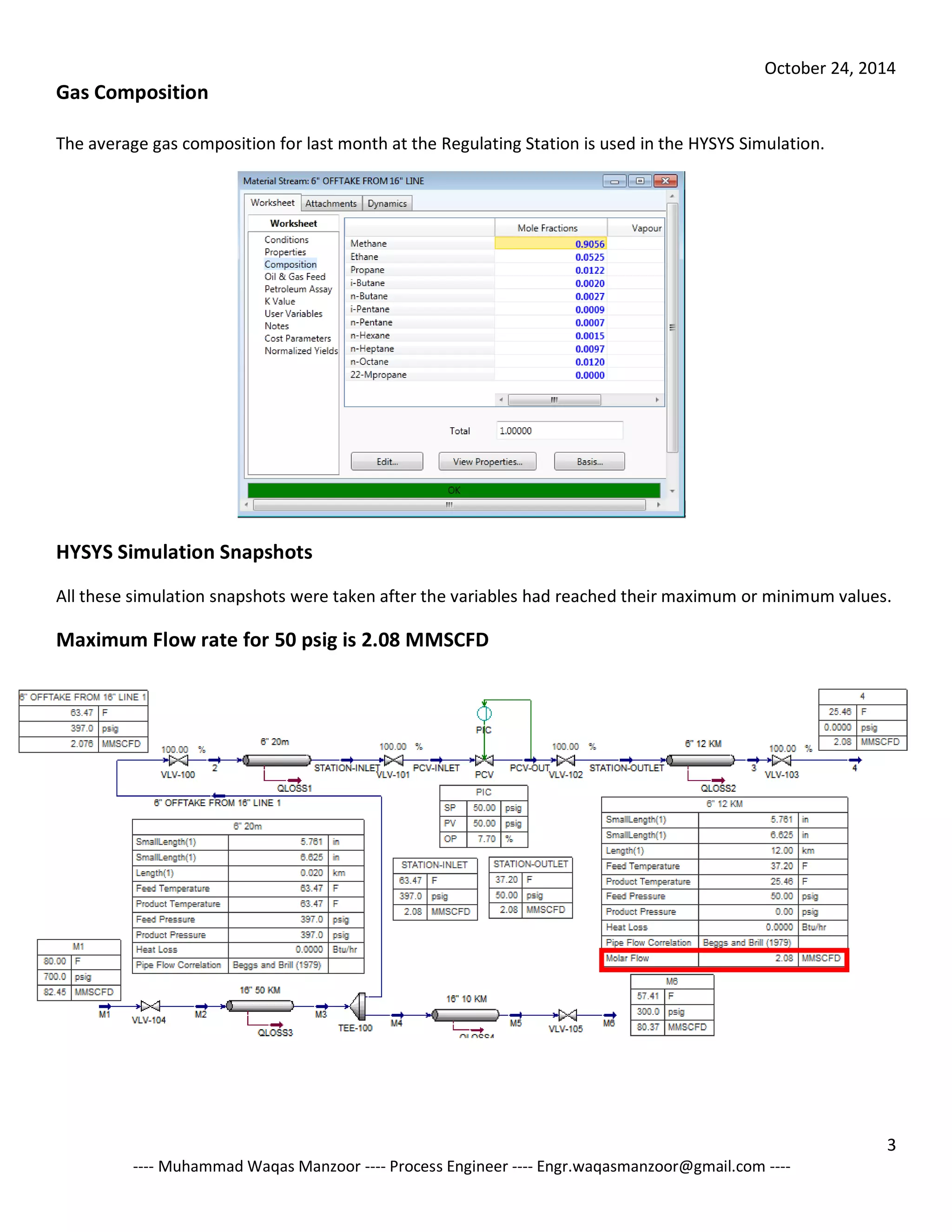

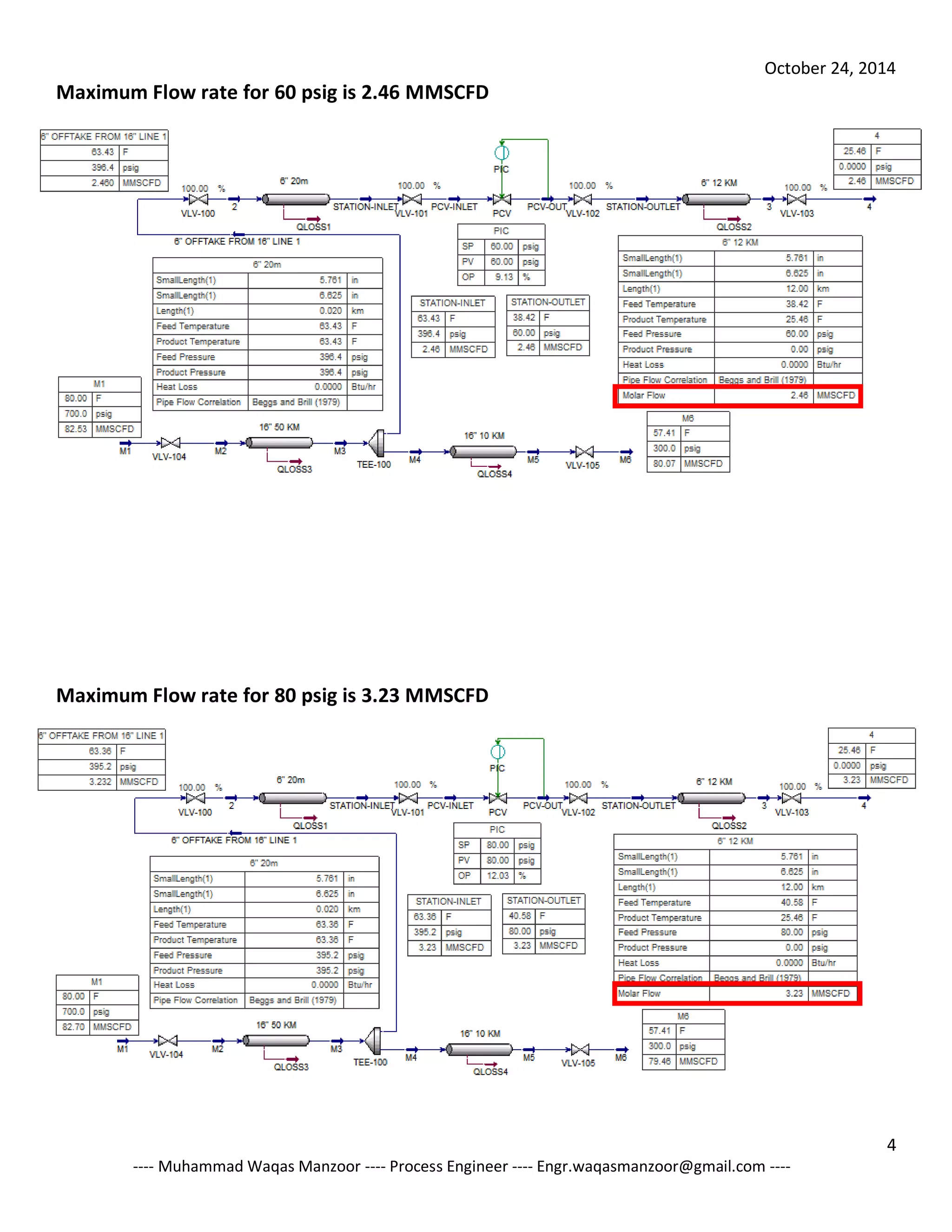

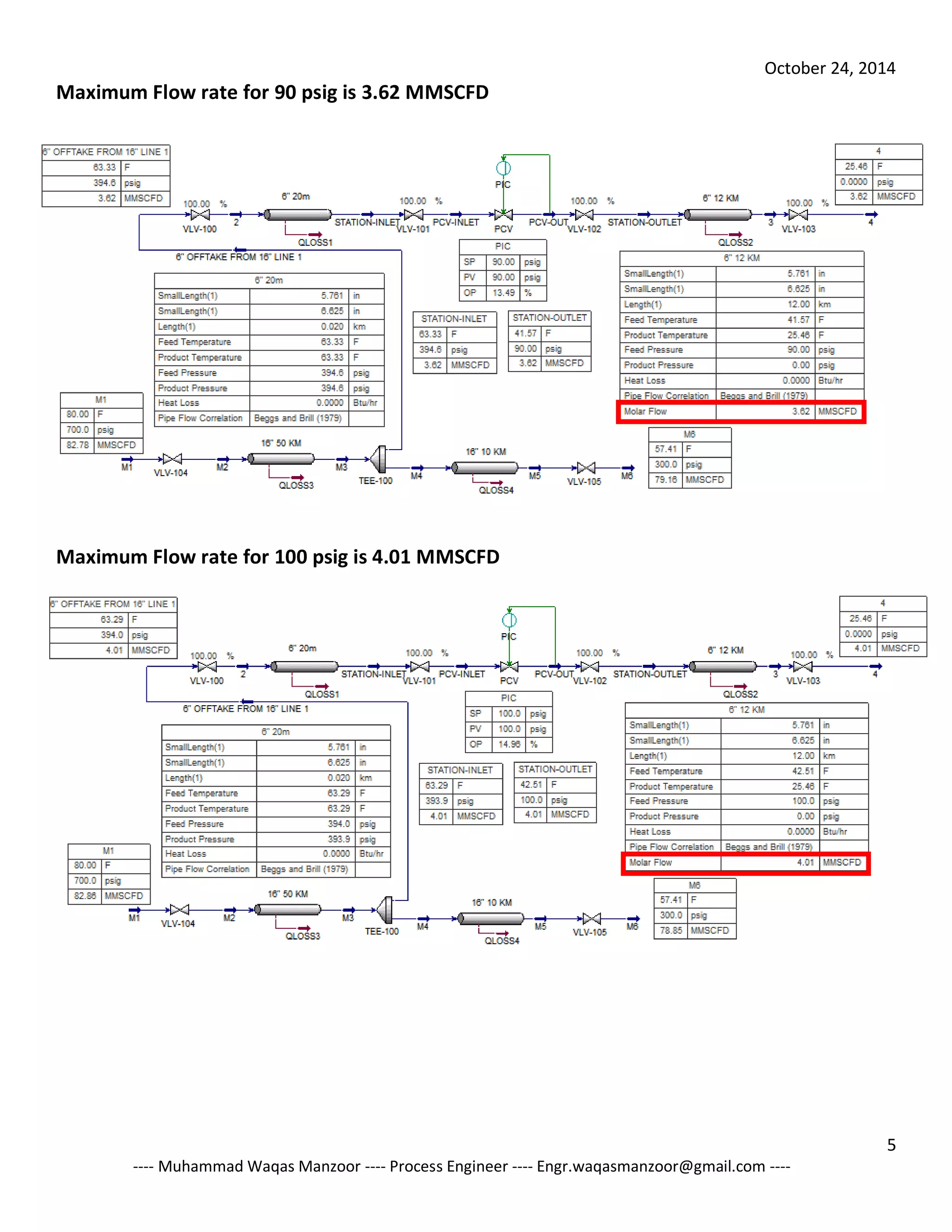

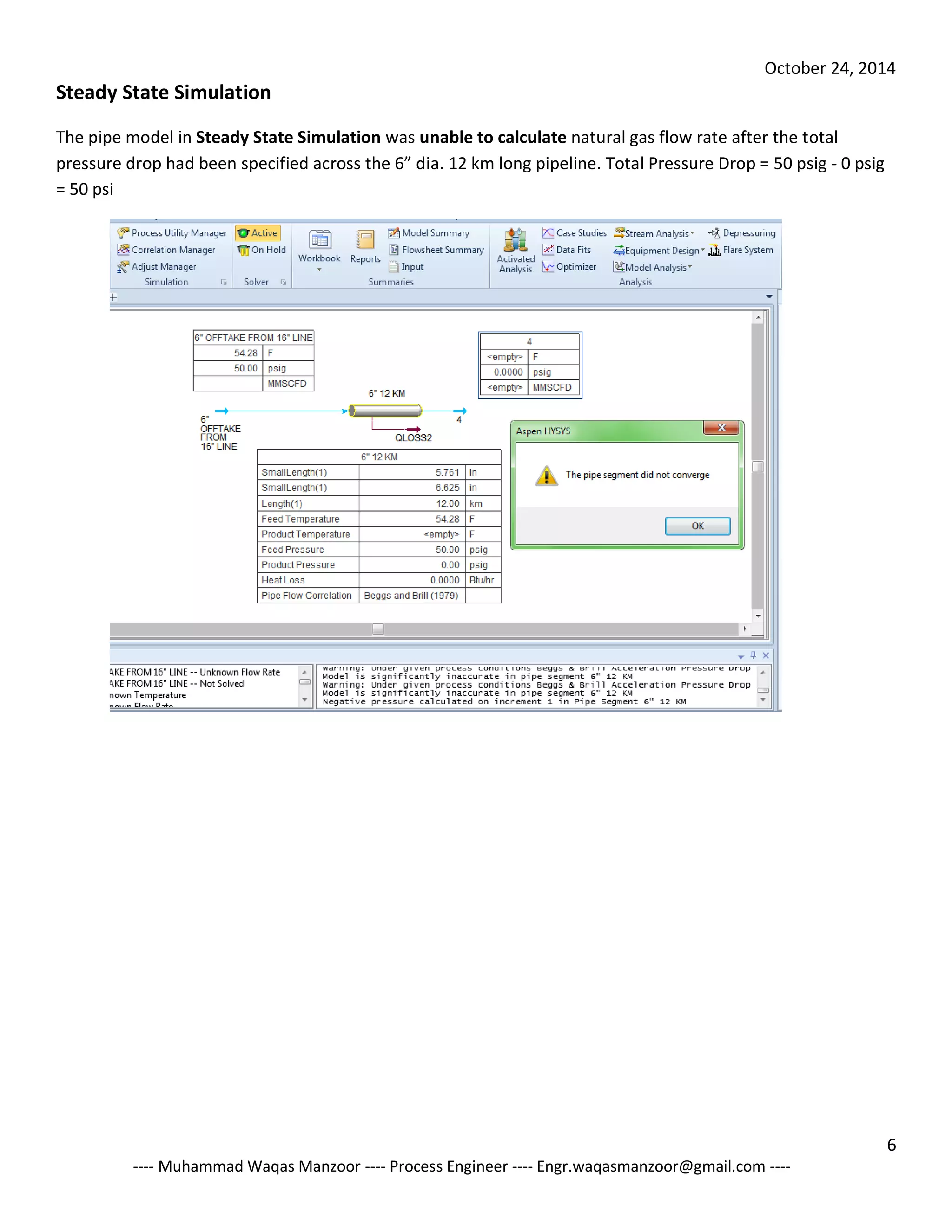

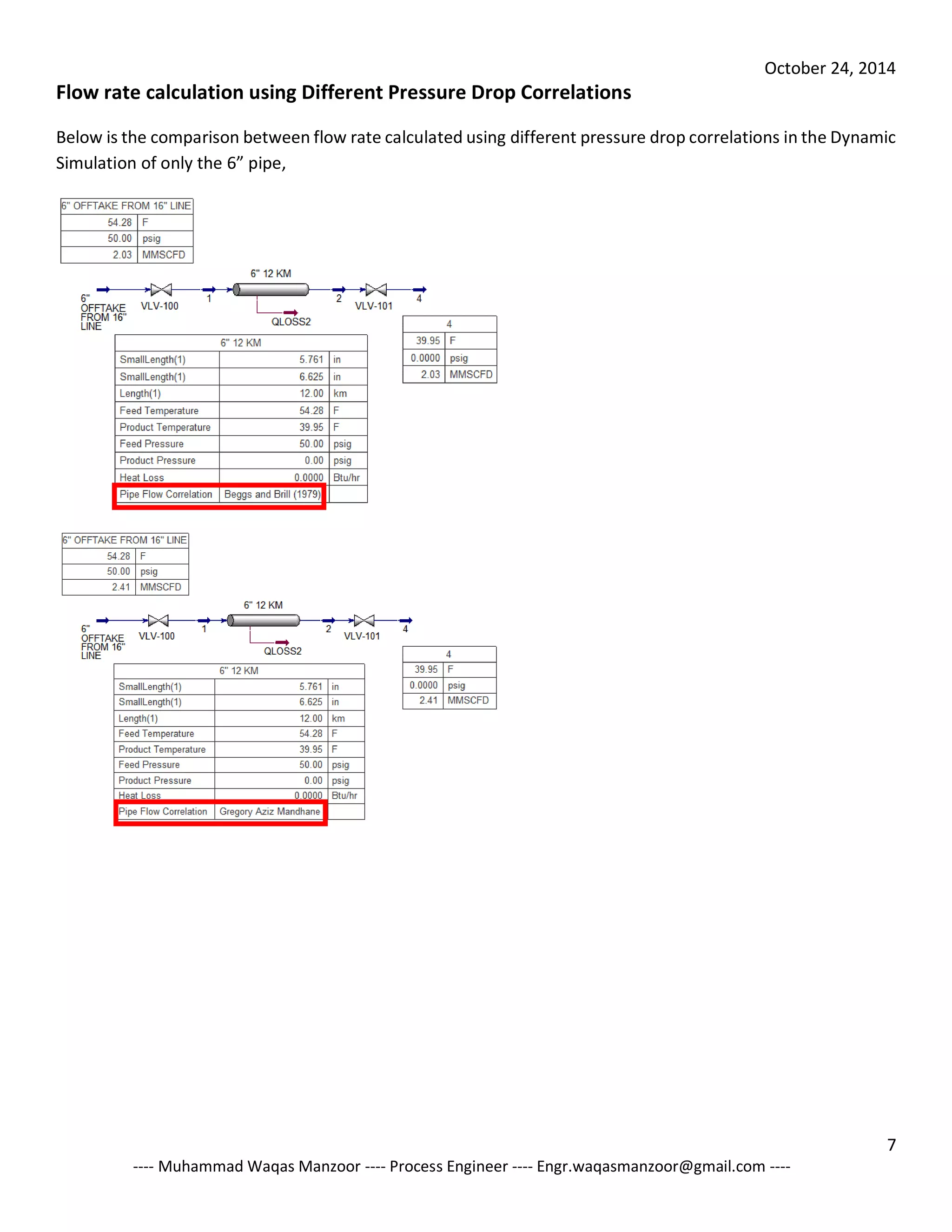

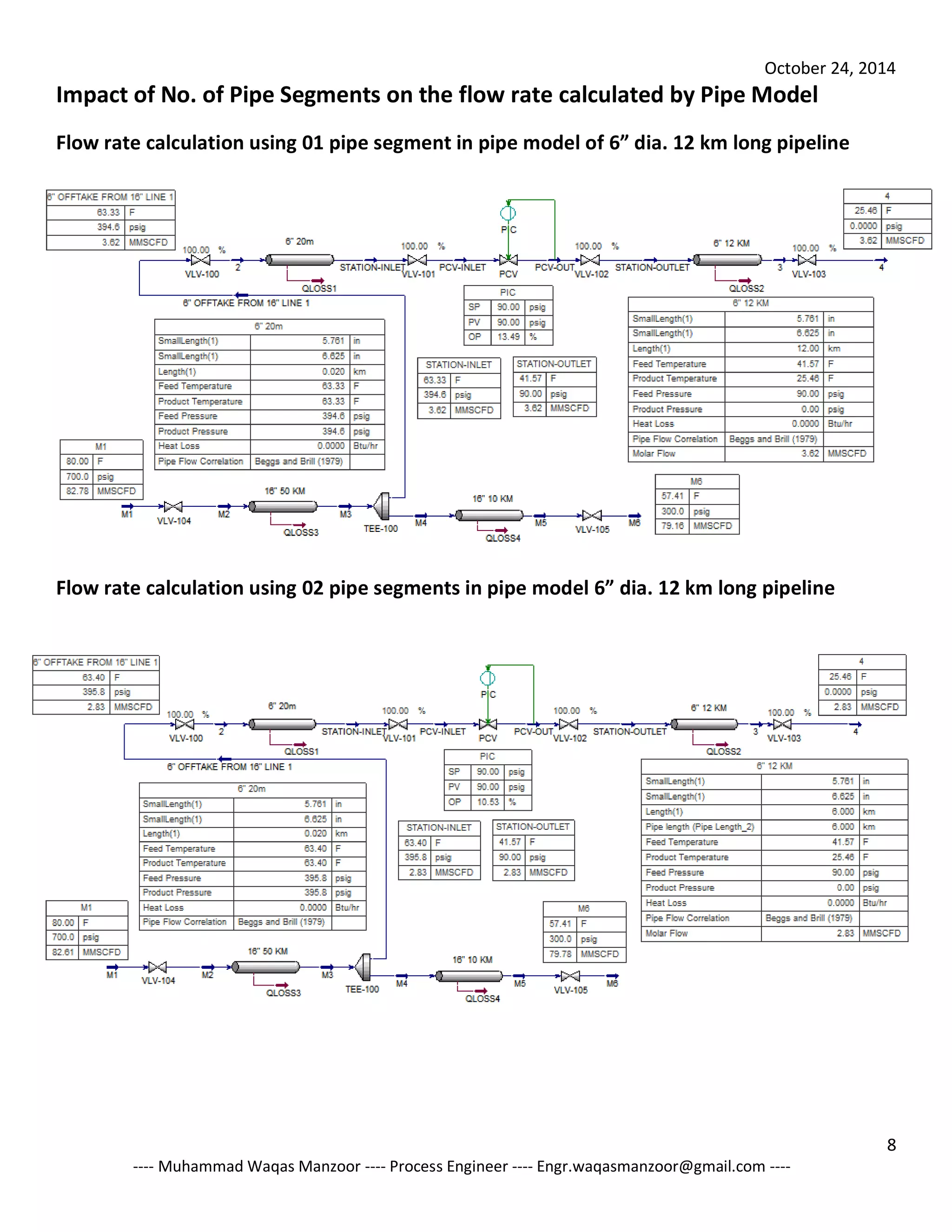

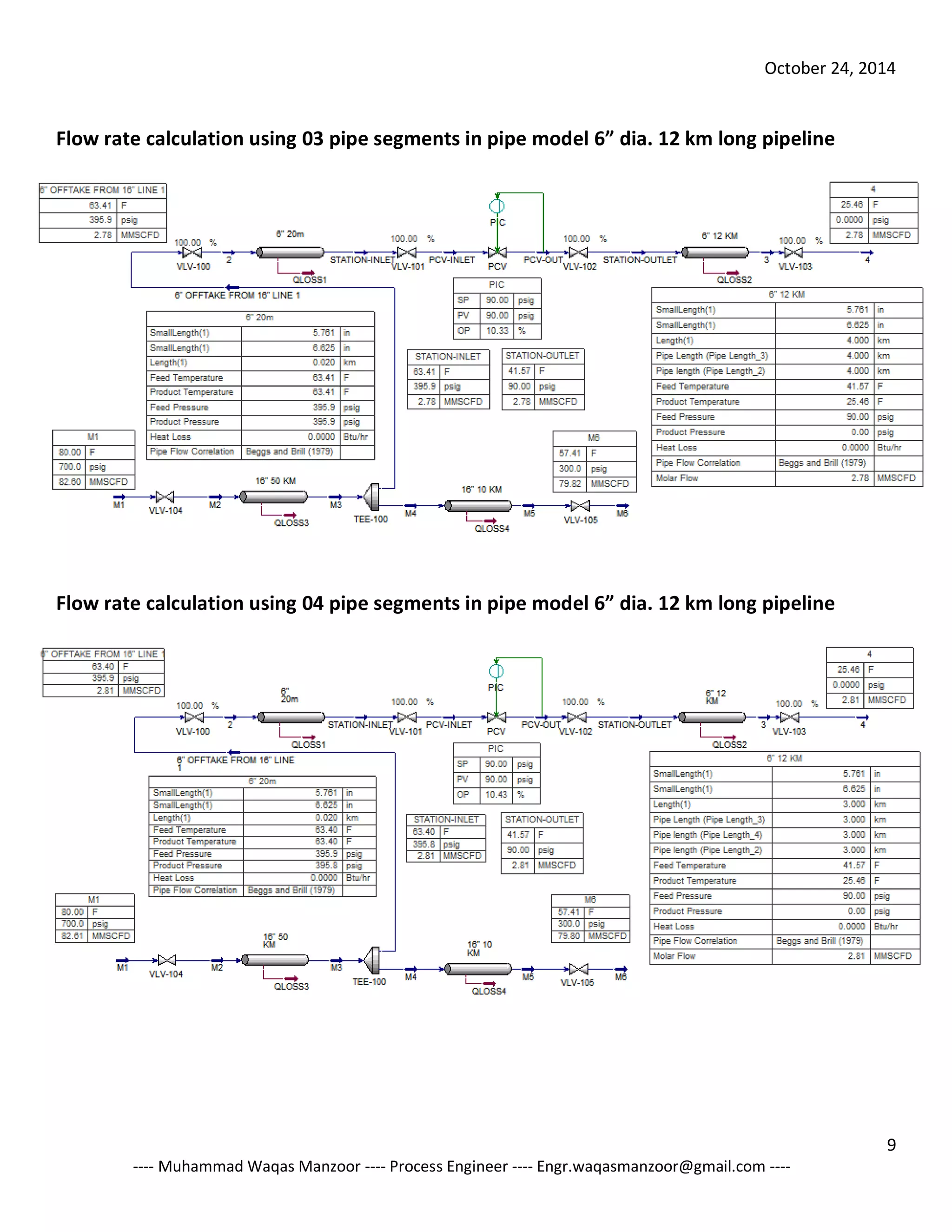

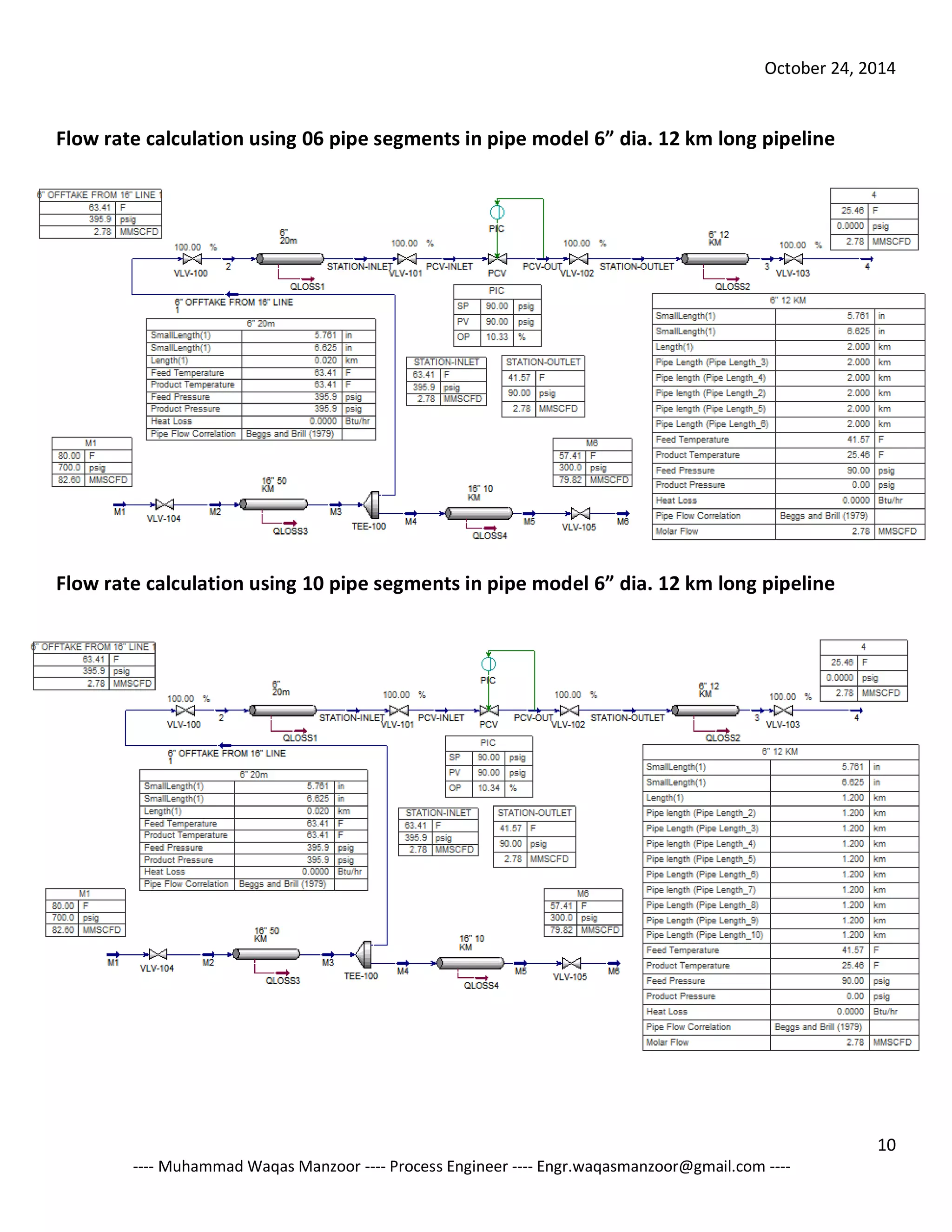

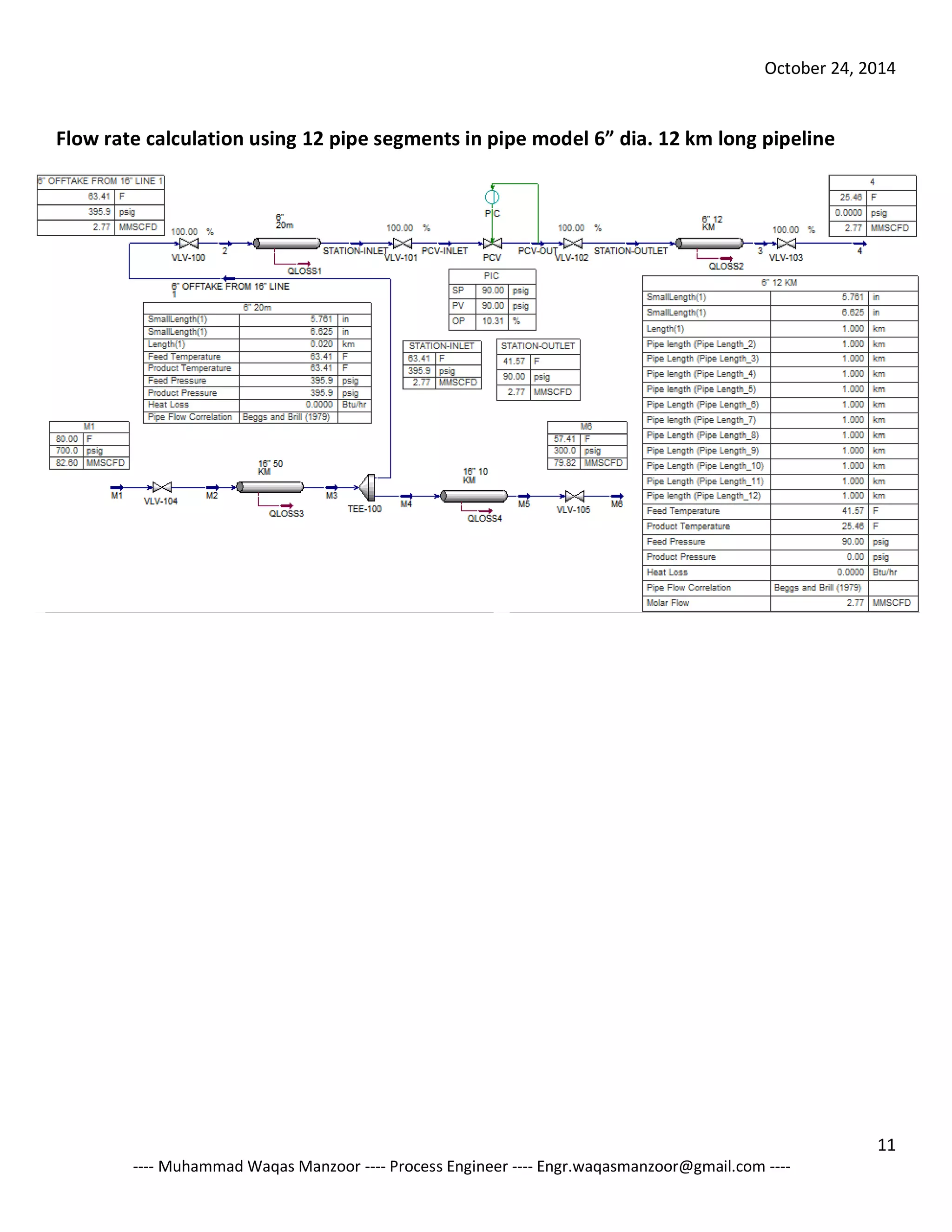

A dynamic simulation was performed in Aspen HYSYS to calculate the maximum flow rate of natural gas through a 12 km long 6" pipeline. The simulation showed that maximum flow rates of 2.08, 2.46, 3.23, 3.62 and 4.01 MMSCFD were achieved at downstream pressures of 50, 60, 80, 90 and 100 psig respectively. A steady state simulation could not calculate flow rates after specifying the total pressure drop across the pipeline. The actual maximum flow rate would be lower than calculated due to higher pipe roughness over time. The pipeline may be unable to meet a forecasted demand above 4 MMSCFD in 2015.