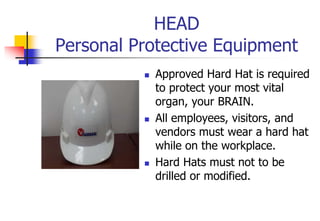

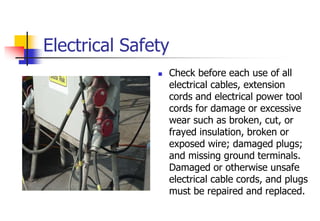

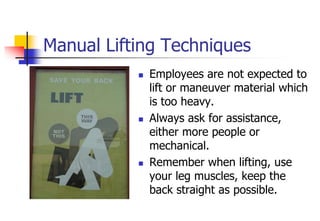

This document provides an overview of safety policies and procedures for Fairdeal QHSE. It defines key safety terms and outlines responsibilities for management, supervisors, and employees to ensure a safe work environment and prevent accidents. Specific safety topics covered include personal protective equipment, housekeeping, electrical safety, fire prevention, lifting techniques, confined spaces, and prohibited behaviors. Management is responsible for training and safety compliance, while employees must follow safety rules and report any issues or injuries. Non-compliance may result in disciplinary actions up to termination.