Hitachi ex550 5 excavator service repair manual

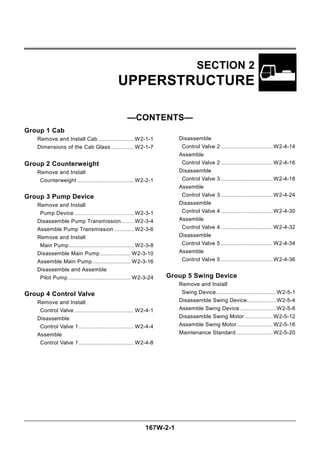

- 1. 167W-2-1 SECTION 2 UPPERSTRUCTURE —CONTENTS— Group 1 Cab Remove and Install Cab ...................... W2-1-1 Dimensions of the Cab Glass .............. W2-1-7 Group 2 Counterweight Remove and Install Counterweight ................................... W2-2-1 Group 3 Pump Device Remove and Install Pump Device ..................................... W2-3-1 Disassemble Pump Transmission........ W2-3-4 Assemble Pump Transmission ............ W2-3-6 Remove and Install Main Pump ........................................ W2-3-8 Disassemble Main Pump................... W2-3-10 Assemble Main Pump........................ W2-3-16 Disassemble and Assemble Pilot Pump....................................... W2-3-24 Group 4 Control Valve Remove and Install Control Valve ..................................... W2-4-1 Disassemble Control Valve 1 .................................. W2-4-4 Assemble Control Valve 1 .................................. W2-4-8 Disassemble Control Valve 2 ................................ W2-4-14 Assemble Control Valve 2 ................................ W2-4-16 Disassemble Control Valve 3 ................................ W2-4-18 Assemble Control Valve 3 ................................ W2-4-24 Disassemble Control Valve 4 ................................ W2-4-30 Assemble Control Valve 4 ................................ W2-4-32 Disassemble Control Valve 5 ................................ W2-4-34 Assemble Control Valve 5 ................................ W2-4-36 Group 5 Swing Device Remove and Install Swing Device..................................... W2-5-1 Disassemble Swing Device.................. W2-5-4 Assemble Swing Device ...................... W2-5-8 Disassemble Swing Motor ................. W2-5-12 Assemble Swing Motor ...................... W2-5-16 Maintenance Standard....................... W2-5-20

- 2. 167W-2-2 Group 6 Pilot Valve Remove and Install Right Pilot Valve ......................................... W2-6-1 Remove and Install Left Pilot Valve ......................................... W2-6-4 Remove and Install Travel Pilot Valve............................... W2-6-7 Disassemble Front Attachment Pilot Valve ......................................... W2-6-8 Assemble Front Attachment Pilot Valve ....................................... W2-6-10 Disassemble Travel Pilot Valve ....................................... W2-6-14 Assemble Travel Pilot Valve ....................................... W2-6-16 Group 7 Pilot Shut-Off Valve Remove and Install Pilot Shut-off Valve ............................ W2-7-1 Disassemble Pilot Shut-off Valve ......... W2-7-4 Assemble Pilot Shut-off Valve.............. W2-7-6 Group 8 Shockless Valve Remove and Install Front Attachment Shockless Valve.............. W2-8-1 Disassemble and Assemble Front Attachment Shockless Valve.............. W2-8-4 Remove and Install Travel Shockless Valve...................... W2-8-7 Disassemble and Assemble Travel Shockless Valve...................... W2-8-8 Group 9 Solenoid Valve Remove and Install Three-Spool Solenoid Valve............... W2-9-1 Disassemble and Assemble Three-Spool Solenoid Valve............... W2-9-3

- 3. UPPERSTRUCTURE / Cab W2-1-1 REMOVE AND INSTALL CAB Remove Cab 1. Remove seat mounting nut (2) to remove seat (1). : 13 mm 2. Loosen bolt (5) in the cab rear section and bolt (6) in rear boxes (3 and 4) to remove rear boxes (3 and 4). : 13 mm 3. Loosen bolt (8) to remove lower cover (7) of the rear box. : 13 mm 4. Remove filter (24) and loosen screw (9) to remove duct (10) from the cab. W157-02-01-005 W157-02-01-017 W158-02-01-001 1 2 3 6 5 6 5 4 7 8 24 10 9

- 4. UPPERSTRUCTURE / Cab W2-1-2 5. Disconnect harness connectors (11) located at the rear inside the cab. 6. Disconnect connectors for wiper limit switch (12), cab light (13), speaker (14), antenna (15) and ground (17) located in the cab. Remove washer vinyl hose (16) located behind the cab. 7. Remove cap (20) from duct cover (18). Loosen screws (19) to remove duct cover (18). 8. While pushing the mating face of duct (21) back- ward, remove duct (21). W167-02-01-001 W162-02-01-002 W158-02-01-002 W157-02-01-011 Duct Mating Face 13 14 12 15 16 17 18 19 20 21 11

- 5. UPPERSTRUCTURE / Cab W2-1-3 9. Attach a sling belt to the top of the cab. CAUTION: Cab weight: 260 kg (573 lb) 10. Remove cab mounting bolt (22) and nuts (23). : 17 mm : 24 mm : 8 mm 11. Slowly lift the cab with a crane to remove the cab from the machine. W157-02-01-009 W157-02-01-010 W157-02-01-001 22 23 23

- 6. UPPERSTRUCTURE / Cab W2-1-4 Install Cab 1. Attach cab to crane with sling belts and install cab onto the machine. CAUTION: Cab weight: 260 kg (573 lb) 2. Tighten cab mounting bolts (22) and nuts (23). : 17 mm : 49 N⋅m (5 kgf⋅m, 36 lbf⋅ft) : 24 mm : 205 N⋅m (21 kgf⋅m, 152 lbf⋅ft) : 8 mm : 64 N⋅m (6.5 kgf⋅m, 47 lbf⋅ft) 3. Install duct (10) into the cab and tighten screw (9). Install filter (24). : 4.9 N⋅m (0.5 kgf⋅m, 3.6 lbf⋅ft) 4. Connect harness connectors (11) at the rear, in- side the cab. W157-02-01-001 W157-02-01-010 W158-02-01-001 W167-02-01-001 22 23 23 11 24 10 9

- 7. UPPERSTRUCTURE / Cab W2-1-5 5. Connect wiper limit switch (12), cab light (13), speaker (14), antenna (15) and ground (17) in the cab. Connect washer vinyl hose (16) behind the cab. : 19.5 N⋅m (2 kgf⋅m, 14.5 lbf⋅ft) 6. Install rear box lower cover (7) and tighten bolts (8). : 13 mm : 19.5 N⋅m (2 kgf⋅m, 14.5 lbf⋅ft) 7. Install rear boxes (3 and 4) and tighten bolts (5 and 6). : 13 mm : 19.5 N⋅m (2 kgf⋅m, 14.5 lbf⋅ft) 8. Push duct (21) to the cab front until the duct mat- ing face comes in contact. W162-02-01-002 W157-02-01-017 W157-02-01-011 13 14 12 15 16 17 3 6 5 6 5 4 7 8 Duct Mating Face 21

- 8. UPPERSTRUCTURE / Cab W2-1-6 9. Install duct cover (18). Tighten screw (19) and put cap (20) on. 10. Install seat (1) and tighten nut (2). : 13 mm : 19.5 N⋅m (2 kgf⋅m, 14.5 lbf⋅ft) W158-02-01-002 W157-02-01-005 18 19 20 1 2

- 9. UPPERSTRUCTURE / Cab W2-1-7 DIMENSIONS OF THE CAB GLASS W157-02-01-013 NOTE: Material: JIS- R3211,R3212 ANSI - AS2 ECE - ANNEX5 or equivalent Unit : mm NOTE : 1 mm=0.03937 in Section B Section A 4-φ13 +0 -1 (5 mm) 51.03 360.78 30 142.25 221.399 580 R9487 4° (87.81) (64.74) 3.015 154.81 43.59 66.84 (5 mm) (4 mm) R9509 R209 R4009 R84 R509 R1009 R4009 R2309 R11509 2-R59 87.84 66.41 905 4-R62 756 612 63.97 35.73 947.152 900.7 15 216.73 222.65 230.50 558.78 164.12 188.5 391.8 25.106 R118 R15 R3018 R78 R11516 R70 R2 Chamfer fringe comers. Chamfer both fringes All Around c1 All Around c1 B A

- 10. UPPERSTRUCTURE / Cab W2-1-8 W157-02-01-014 Section C and D 2-φ12.2 +0.5 -0 541.5 910 833±1.0 370±1.0 503±1.0 728.5±1.0 728.5±1.0 398.5±1.0 337.5±1.0 333.5±1.0 60.1 61.8 3.1 39.5 39.5 10.6 3-R4 R1985.1 R3985.4 R2285.4 (38.5) (38.5) (5 mm) (5 mm) (4 mm) (4 mm) 9.2 22.5 40 40 R105 475.8 113.9 488.5 208 Chamfer both fringes Chamfer both fringes Chamfer fringe comers. Chamfer fringe comers. Chamfer fringe corners. Chamfer fringe comers. C R3 45.67 90.672 549.86 516.26 468.17 7735.4 33.60 50.71 39.63 19.70 19.29 740.51 904.13 165 74.95 213.97 276.58 227.39 890.03 59 11.22 18 8 980 753.99 290 R120885.4 R12.5 R120 R8075 R3877 R2590 R5175 R345 R895 R295 R595 R1145 R12095 R1995 R2477 R72.5 R30 D 2-φ12.2 +0.5 -0 4-R5 2-R5 2-R4 Unit : mm NOTE : 1 mm=0.03937 in

- 11. UPPERSTRUCTURE / Counterweight W2-2-1 REMOVE AND INSTALL COUNTER- WEIGHT Removal CAUTION: Approximate counterweight weight: 10500 kg (23200 lb) 1. Install lifting accessories and wire ropes to sling brackets on the top of the counterweight. Set the wire rope taut using a crane. CAUTION: Watch out the power-wrench re- action bar movement. Take care not to be hit the reaction bar. 2. Loosen bolts (10) using a power wrench to re- move bolts (10), nuts (8), shims (7), and washers (9). NOTE: Shims (7) are used only when any gap be- tween nuts (8) and the lock brackets exist. When no gap exists, shims are not re- quired. : 65 mm 3. Loosen bolts (1) to remove lock washers (2), washers (3), and spacers (4). If shims (5 and 6) are provided, remove shims (5 and 6). : 36 mm 4. Remove the counterweight using a crane. W166-02-02-002 W166-02-02-003 W166-02-02-001 1 10 9 8 7 9 2 6 4 5 3 1 2 7 3 4 5 9 8 6 10 9 2,1 6,5,4 3 8 7 9

- 12. UPPERSTRUCTURE / Counterweight W2-2-2 Installation CAUTION: Approximate counterweight weight: 10500 kg (23200 lb) 1. Install lifting accessories and wire ropes to sling brackets on the top of the counterweight. Then, lift the counterweight by crane. CAUTION: Do not allow anyone under the lifted counterweight. 2. Insert protrusions on the counterweight into holes on the frame to install the counterweight. CAUTION: Watch out the power-wrench re- action bar movement. Take care not to be hit the reaction bar. IMPORTANT: Apply lubricant to bolts (10) before installing. Install shims (7) between nuts (4) and the lock brackets with the flange positioned in the upper side. 3. Install bolts (10), nuts (4), shims (7), and washers (9). Using a power wrench, tighten bolts (10). : 65 mm : 2750 N⋅m (280 kgf⋅m, 2030 lbf⋅ft) 4. Install shims (5 and 6), spacers (4), washers (3) lock washers (2), and bolts (1). Remove wire ropes and lifting accessories. : 36 mm : 440 N⋅m (45 kgf⋅m, 330 lbf⋅ft) W166-02-02-002 W166-02-02-003 W166-02-02-001 1 10 9 8 7 9 2 6 4 5 3 1 2 7 3 4 5 9 8 6 10 9 2,1 6,5,4 3 8 7 9

- 13. UPPERSTRUCTURE / Pump Device W2-3-1 REMOVE AND INSTALL PUMP DEVICE CAUTION: 1. Escaping fluid under pressure can penetrate the skin, causing serious injury. Avoid this hazard by relieving pressure before disconnecting hydraulic lines. 2. Hydraulic oil may be hot after operation. Hot hydraulic oil may spout, possibly causing severe burns. Be sure to wait for oil to cool before starting any repair work. 3. The hydraulic oil tank cap may fly off by remaining pressure if removed quickly. Slowly loosen the cap to completely release any remaining pressure. Preparation 1. Stop the engine. Move all control levers to release pressure remaining in the system. Turn the hydraulic oil tank cap approx. 30° coun- terclockwise to release any pressure remaining in the hydraulic tank.

- 14. UPPERSTRUCTURE / Pump Device W2-3-2 Removal 1. Disconnect all hoses and electrical cables from the pump. Tightening Torque Wrench size (mm) N⋅m kgf⋅m lbf⋅ft Remark : 19 29.5 3 22 Piping : 22 59 6 44 Piping : 27 93 9.5 69 Piping : 36 175 18 130 Piping : 10 108 11 80 Piping : 12 175 18 130 Piping : 14 265 27 195 Piping : 30 390 40 290 Bolt : 16 69 7 50 Bolt : 32 540 55 400 Bolt 2. Lay a wooden block (300 mm long, 200 mm wide, and 20 mm thick) under the engine oil pan. CAUTION: Main pump weight: 125 kg (276 lb) 3. Remove the main pump mounting bolts to remove the main pump. CAUTION: Pump transmission weight: 150 kg (330 lb) 4. Remove the pump transmission mounting bolts and the engine rear mounting bolts to remove the pump transmission. Installation NOTE: Refer to the “removal” section above for wrench sizes and tightening torque. 1. Secure the pump device with the mounting bolts. 2. Re-connect all hoses and electrical cables to the pump device. 3. Bleed any trapped air from the pump (refer to page W1-1-2). IMPORTANT: After installing the pump, be sure to perform break-in operation to pre- vent seizure. Break-In Operation Process: 1. Start the engine and run at slow idle speed for 20 minutes. Check for oil leaks while running at slow idle. 2. Increase the engine speed to the fast idle speed. Raise and lower the boom for 20 min- utes repeatedly. (Do not operate the control levers quickly. Slowly move the levers to full stroke.) W167-02-03-005 W167-02-03-003 Wooden Block Engine Rear Mounting Bolt Main Pump Mounting Bolt Pump Transmission Mounting Bolt

- 15. UPPERSTRUCTURE / Pump Device W2-3-3 (Blank)

- 16. UPPERSTRUCTURE / Pump Device W2-3-4 DISASSEMBLE PUMP TRANSMISSION W167-02-03-001 1 - Casing 4 - Coupling 7 - Bearing 10 - Bolt (10 Used) 2 - Bearing 5 - Retaining Ring 8 - O-Ring 11 - Oil Seal 3 - Retaining Ring 6 - Gear 9 - Cartridge 12 - Drain Plug 11 2 10 3 4 5 6 7 8 9 1

- 17. UPPERSTRUCTURE / Pump Device W2-3-5 Disassemble Pump Transmission • Be sure to thoroughly read all precautions for disas- sembly/assembly work on page W1-1-1 before start- ing any repair work. 1. Loosen drain plug (12) to drain gear oil from the pump transmission. Remove the pilot pump from casing (1). : 27 mm : 8mm CAUTION: Pump transmission weight: 150 kg (330 lb) 2. Place casing (1) on a work bench with the main pump mounting side facing downward. 3. Remove bolts (10). : 19 mm CAUTION: Pump transmission weight: 150 kg (330 lb) 4. Turn casing (1) over and place it on a work bench. NOTE: At this time, set a wooden block (100 mm high) so that it does not come in contact with cartridge (9). 5. Attach a protection plate (Dia. 50 mm) to coupling (4). While tapping the protection plate, remove cartridge (9), bearing (2 and 7) and gear (6) from casing (1). 6. Remove bearing (7), O-ring (8) and oil seal (11) from cartridge (9). 7. Remove retaining ring (3), coupling (4) and retain- ing ring (5) from gear (6). 8. Using a press or a puller, remove bearings (2 and 7) from gear (6).

- 18. UPPERSTRUCTURE / Pump Device W2-3-6 ASSEMBLE PUMP TRANSMISSION W167-02-03-002 1 - Casing 4 - Coupling 7 - Bearing 10 - Bolt (10 Used) 2 - Bearing 5 - Retaining Ring 8 - O-Ring 11 - Oil Seal 3 - Retaining Ring 6 - Gear 9 - Cartridge 12 - Drain Plug A A Pilot Pump Section A-A 10 12 3 2 6 1 4 5 9 8 11 7

- 19. UPPERSTRUCTURE / Pump Device W2-3-7 Assemble Pump Transmission 1. Press bearings (2 and 7) into gear (6). 2. Install retaining ring (5), coupling (4), and retaining ring (3) to gear (6). CAUTION: Casing (1) weight: 95 kg (210 lb) 3. With the main pump mounting face .downward, place casing (1) on a work bench. 4. Press bearing (2) along with gear (6) into casing (1). 5. Using a protection plate, press oil seal (11)into cartridge (9). 6. Coat the inner diameter of oil seal (11) with grease. 7. Install O-ring (8) to cartridge (9). IMPORTANT: Position the casting imprint on car- tridge (9) upward (the oil filler side) and install the cartridge on casing (1). 8. Install cartridge (9) on casing (1). 9. Tighten bolts (10) (10 used). : 19 mm : 88 N⋅m (9 kgf⋅m, 65 lbf⋅ft) 10. Install the pilot pump on casing (1). : 8 mm : 64 N⋅m (6.5 kgf⋅m, 47 lbf⋅ft) W167-02-03-006 Casting Imprint Upward

- 20. UPPERSTRUCTURE / Pump Device W2-3-8 REMOVE AND INSTALL MAIN PUMP CAUTION: 1. Escaping fluid under pressure can penetrate the skin, causing serious injury. Avoid this hazard by relieving pressure before disconnecting hydraulic lines. 2. Hydraulic oil may be hot after operation. Hot hydraulic oil may spout, possibly causing severe burns. Be sure to wait for oil to cool before starting any repair work. 3. The hydraulic oil tank cap may fly off by remaining pressure if removed quickly. Slowly loosen the cap to completely release any remaining pressure. Preparation 1. Stop the engine. Move all control levers to release pressure remaining in the system. Turn the hydraulic oil tank cap approx. 30° coun- terclockwise to release any pressure remaining in the hydraulic tank.

- 21. UPPERSTRUCTURE / Pump Device W2-3-9 Removal 1. Disconnect all hoses and electrical cables from the pump. : 19 mm : 29.5 N⋅m (3 kgf⋅m, 22 lbf⋅ft) : 22 mm : 59 N⋅m (6 kgf⋅m, 44 lbf⋅ft) : 27 mm : 93 N⋅m (9.5 kgf⋅m, 69 lbf⋅ft) : 36 mm : 175 N⋅m (18 kgf⋅m, 130 lbf⋅ft) : 10 mm : 108 N⋅m (11 kgf⋅m, 80 lbf⋅ft) : 12 mm : 175 N⋅m (18 kgf⋅m, 130 lbf⋅ft) : 14 mm : 265 N⋅m (27 kgf⋅m, 195 lbf⋅ft) CAUTION: Main pump weight: Approx. 125 kg (276 lb) 2. Remove the main pump mounting bolts to remove the main pump. : 30 mm : 390 N⋅m (40 kgf⋅m, 290 lbf⋅ft) Installation NOTE: Refer to the “Removal” section above for wrench sizes and tightening torque. 1. Secure the pump device with the mounting bolts. 2. Re-connect all hoses and electrical cables to the pump device. 3. Bleed any trapped air from the pump (refer to page W1-1-2). IMPORTANT: After completing installation of the pump device, be sure to perform break-in operation to prevent pump seizure during initial machine opera- tion. Procedure: 1. Start the engine. Run at slow idle speed for 20 minutes. Check for oil leaks during this opera- tion. 2. Increase the engine speed to the first idle speed and raise or lower the boom for 20 min- utes. (Do not operate the control lever quickly. Slowly operate the lever full stroke.) T167-01-02-003 Main Pump Mounting Bolt

- 22. UPPERSTRUCTURE / Pump Device W2-3-10 DISASSEMBLE MAIN PUMP W116-02-04-048 Pump displacement Angle Sensor (6) W116-02-04-049 1 - Retaining Ring 8 - Socket Bolt 15 - Shaft 22 - Washer 2 - Seal Case 9 - Socket Bolt (4 Used) 16 - Spring 23 - Socket Bolt (2 Used) 3 - Oil Seal 10 - Regulator 17 - Oil Seal 24 - Spring 4 - O-Ring 11 - Control Plate 18 - Retainer 25 - Spring Seat 5 - Housing 12 - Rotary Group 19 - Retaining Ring 26 - Arm 6 - Pump Displacement Angle Sensor (A-Sensor) 13 - Socket Bolt (3 Used) 20 - O-Ring 27 - Set Screw (2 Used) 7 - Socket Bolt (3 Used) 14 - Case 21 - Potentiometer 28 - O-Ring 1 4 3 2 5 A 6 7 8 9 12 10 9 11 13 14 28 23 22 21 15 24 25 26 27 20 16 17 18 19

- 23. UPPERSTRUCTURE / Pump Device W2-3-11 Regulator (10) W116-02-04-050 Regulator Cover (29) Section W116-02-04-051 29 - Regulator Cover 38 - Plate 47 - Lock Nut 56 - Guide (2 Used) 30 - Socket Bolt (4 Used) 39 - Socket Bolt (4 Used) 48 - Guide 57 - Steel Ball (2 Used) 31 - Spring Seat 40 - Piston Ring (2 Used) 49 - O-Ring 58 - Plug (2 Used) 32 - Spring 41 - Piston 50 - Adjusting Screw 59 - Plug (2 Used) 33 - Spring 42 - Packing 51 - O-Ring 60 - O-Ring (6 Used) 34 - Pump Control Solenoid Valve 43 - Rod 52 - Spring 61 - Retainer 35 - Body 44 - Knock Pin (2 Used) 53 - Distant Piece 62 - O-Ring 36 - Set Screw 45 - Bushing 54 - Spool 63 - Filter 37 - O-Ring 46 - Pin 55 - Barrel 30 29 31 32 33 A 34 46 45 44 41 40 43 42 39 38 37 36 63 29 62 61 60 56 57 58 59 59 58 57 56 47 30 48 49 50 51 52 53 54 55

- 24. UPPERSTRUCTURE / Pump Device W2-3-12 W116-02-04-048 Pump Displacement Angle Sensor (6) W116-02-04-049 1 4 3 2 5 A 6 7 8 9 12 10 9 11 13 14 28 23 22 21 15 24 25 26 27 20 16 17 18 19

- 25. UPPERSTRUCTURE / Pump Device W2-3-13 Disassemble Main Pump • Be sure to thoroughly read all precautions for disas- sembly/assembly work on page W1-1-1 before start- ing any repair work. CAUTION: Main pump weight: 125 kg (276 lb) 1. Loosen plug (A) to drain-hydraulic oil from the pump. Place the pump on a work bemch with regulator (10) positioned upward. : 10 mm Regulator (10) CAUTION: Regulator (10) weight: 45 kg (100 lb) 2. Remove socket bolts (7, 8, and 9). Install eye bolt (M16, pitch 2.0) to regulator (10). : 14 mm IMPORTANT: When removing regulator (10) from housing (5), take care not to allow control plate (11) to drop Off. 3. Using a crane, remove regulator (10) from hous- ing (5). 4. Secure cylinder block to the center pin with a rub- ber washer and bolt (M6, 55mm long) so that the cylinder block does not come off when housing (5) is turned over. : 10 mm Rotary Group (12) CAUTION: Housing (5) and rotary group (12) assembly weight: 80 kg (176 lb) 5. Turn housing (5) over to remove retaining ring (1) from housing (5). 6. Remove seal case (2) from housing (5). Remove O-ring (4) and oil seal (3) from seal case (2). IMPORTANT: Do not disassemble rotary group (12). 7. Install special tool (ST 1428) to the drive shaft threaded hole (M16, pitch 2.0) of rotary group (12) to remove rotary group (12) from housing (5). Special Tool: ST 1428 Pump Displacement Angle Sensor (A-Sensor) 8. Remove socket bolts (13) to remove A-sensor (6) from regulator (10). : 5 mm 9. Remove socket bolts (23) to remove potentiome- ter (21) from case (14). : 5 mm 10. Remove spring (16) from shaft (15). 11. Remove O-ring (20), retaining ring (19) and re- tainer (18) from case (14). 12. Remove set screws (27). Remove arm (26), shaft (15), spring seat (25) and spring (24) from case (14). : 3 mm 13. Remove oil seal (17) from case (14).

- 26. UPPERSTRUCTURE / Pump Device W2-3-14 Regulator (10) W116-02-04-050 Regulator Cover (29) Section W116-02-04-051 30 29 31 32 33 A 34 46 45 44 41 40 43 42 39 38 37 36 63 29 62 61 60 56 57 58 59 59 58 57 56 47 30 48 49 50 51 52 53 54 55

- 27. UPPERSTRUCTURE / Pump Device W2-3-15 Regulator (10) 14. Remove pin (46) and bushing (45) from body (35). 15. Loosen socket bolts (A) to dismount pump control solenoid valve (34). : 3 mm 16. Remove socket bolts (30) (4 used) to remove regulator cover (29) from body (35). : 8 mm 17. Remove spring seat (31) and springs (32 and 33) from body (35). 18. Remove retainer (61) from body (35). Regulator Cover (29) IMPORTANT: When holding regulator cover (29) with a vise, hold faces other than the mating face with body (35). 19. Hold regulator cover (29) with a vise. Loosen and remove guide (48)from regulator cover (29). : 24 mm 20. Remove O-ring (49) from guide (48). IMPORTANT: Do not remove lock nut (47) and ad- justing screw (50). Failure to do so will change the pump flow rate. 21. Remove spring (52), distant piece (53) and spool (54) from regulator cover (29). 22. Remove barrel (55) from regulator cover (29). 23. Remove plug (59) from regulator cover (29). : 8 mm 24. Remove plug (58) to remove steel ball (57) and guide (56) from regulator cover (29). : 6 mm 25. Remove filter (63) from regulator cover (29).

- 28. UPPERSTRUCTURE / Pump Device W2-3-16 ASSEMBLE MAIN PUMP W116-02-04-015 A-Sensor (6) W116-02-04-016 1 - Retaining Ring 8 - Socket Bolt 15 - Shaft 22 - Washer 2 - Seal Case 9 - Socket Bolt (4 Used) 16 - Spring 23 - Socket Bolt (2 Used) 3 - Oil Seal 10 - Regulator 17 - Oil Seal 24 - Spring 4 - O-Ring 11 - Control Plate 18 - Retainer 25 - Spring Seat 5 - Housing 12 - Rotary Group 19 - Retaining Ring 26 - Arm 6 - Pump Displacement Angle Sensor (A-Sensor) 13 - Socket Bolt (3 Used) 20 - O-Ring 27 - Set Screw (2 Used) 7 - Socket Bolt (3 Used) 14 - Case 21 - Potentiometer 28 - O-Ring A Packing (42) 5 12 4 11 10 9 6 8 7 9 Section A-A Section B-B Pin (46) Bushing (45) 28 27 26 14 13 15 24 25 A A B B 16 21 20 22 23 17 18 19 1 2 3

- 29. UPPERSTRUCTURE / Pump Device W2-3-17 Regulator (10) W167-02-03-007 29 - Regulator Cover 38 - Plate 47 - Lock Nut 56 - Guide (2 Used) 30 - Socket Bolt (4 Used) 39 - Socket Bolt (4 Used) 48 - Guide 57 - Steel Ball (2 Used) 31 - Spring Seat 40 - Piston Ring (2 Used) 49 - O-Ring 58 - Plug (2 Used) 32 - Spring 41 - Piston 50 - Adjusting Screw 59 - Plug (2 Used) 33 - Spring 42 - Packing 51 - O-Ring 60 - O-Ring (6 Used) 34 - Pump Control Solenoid Valve 43 - Rod 52 - Spring 61 - Retainer 35 - Body 44 - Knock Pin (2 Used) 53 - Distant Piece 62 - O-Ring 36 - Set Screw 45 - Bushing 54 - Spool 63 - Filter 37 - O-Ring 46 - Pin 55 - Barrel Regulator Cover (29) Section Section X-X Section Y-Y Section A-A 29 31 41 43 35 38 32 33 36 40 37 39 44 42 30 34 A 45 46 59 A 56 57 58 X X Y Y 62 60 61 60 47 50 49 48 51 52 29 53 55 54 63

- 30. Thank you very much for your reading. Please Click Here. Then Get COMPLETE MANUAL. NO WAITING NOTE: If there is no response to click on the link above, please download the PDF document first and then click on it. GET MORE OTHER MANUALS https://www.aservicemanualpdf.com/ GET MORE OTHER MANUALS https://www.aservicemanualpdf.com/

- 31. UPPERSTRUCTURE / Pump Device W2-3-18 W116-02-04-015 A-Sensor W116-02-04-016 A Packing (42) 5 12 4 11 10 9 6 8 7 9 Section A-A Section B-B Pin (46) Bushing (45) 28 27 26 14 13 15 24 25 A A B B 16 21 20 22 23 17 19 1 2 3 18

- 32. UPPERSTRUCTURE / Pump Device W2-3-19 Assemble Main Pump Rotary Group (12) CAUTION: Housing (5) weight: 35 kg (77 lb) 1. Set housing (5) on a work bench with regulator (10) side downward. CAUTION: Rotary group (12) weight: 45 kg (100 lb) 2. Install eye bolt (M16, pitch 2.0) to the drive shaft of rotary group (12). 3. Attach rotary group (12) to a crane and install it into housing (5). 4. Install O-ring (4) to housing (5). 5. Using a protection plate, press oil seal (3) into seal case (2). Install seal case (2) to housing (5). IMPORTANT: Check that retaining ring (1) is in- stalled securely. 6. Install retaining ring (1) to housing (5). CAUTION: Housing (5) and rotary group (12) assembly weight: 80 kg (176 lb) 7. Turn housing (5) over and set it on a Work bench. Remove a bolt and rubber washer from rotary group (12) center pin. : 10 mm 8. Apply a film of THREEBOND #1215 to regulator (10) mounting face on housing (5). Then, install packing (42) on housing (5). Apply a film of THREEBOND #1215 to packing (42). Regulator (10) 9. Install control plate (11) on the slide surface on regulator (10). NOTE: Coat control plate (11) with grease. CAUTION: Regulator (10) weight: Approx. 40 kg (88 lb) 10. Attach regulator (10) to a crane and install it on housing (5). 11. Tighten socket bolts (7) (3 used), (8) and (9) (4 used). : 14mm : 310 to 390 N⋅m (32 to 40 kgf⋅m, 230 to 290 lbf⋅ft) IMPORTANT: Make sure that pin (46) moves smoothly. 12. Install bushing (45) and pin (46) into regulator (10).

- 33. UPPERSTRUCTURE / Pump Device W2-3-20 W116-02-04-015 A-Sensor W116-02-04-016 A Packing (42) 5 12 4 11 10 9 6 8 7 9 Section A-A Section B-B Pin (46) Bushing (45) 28 27 26 14 13 15 24 25 A A B B 16 21 20 22 23 17 19 1 2 3 18