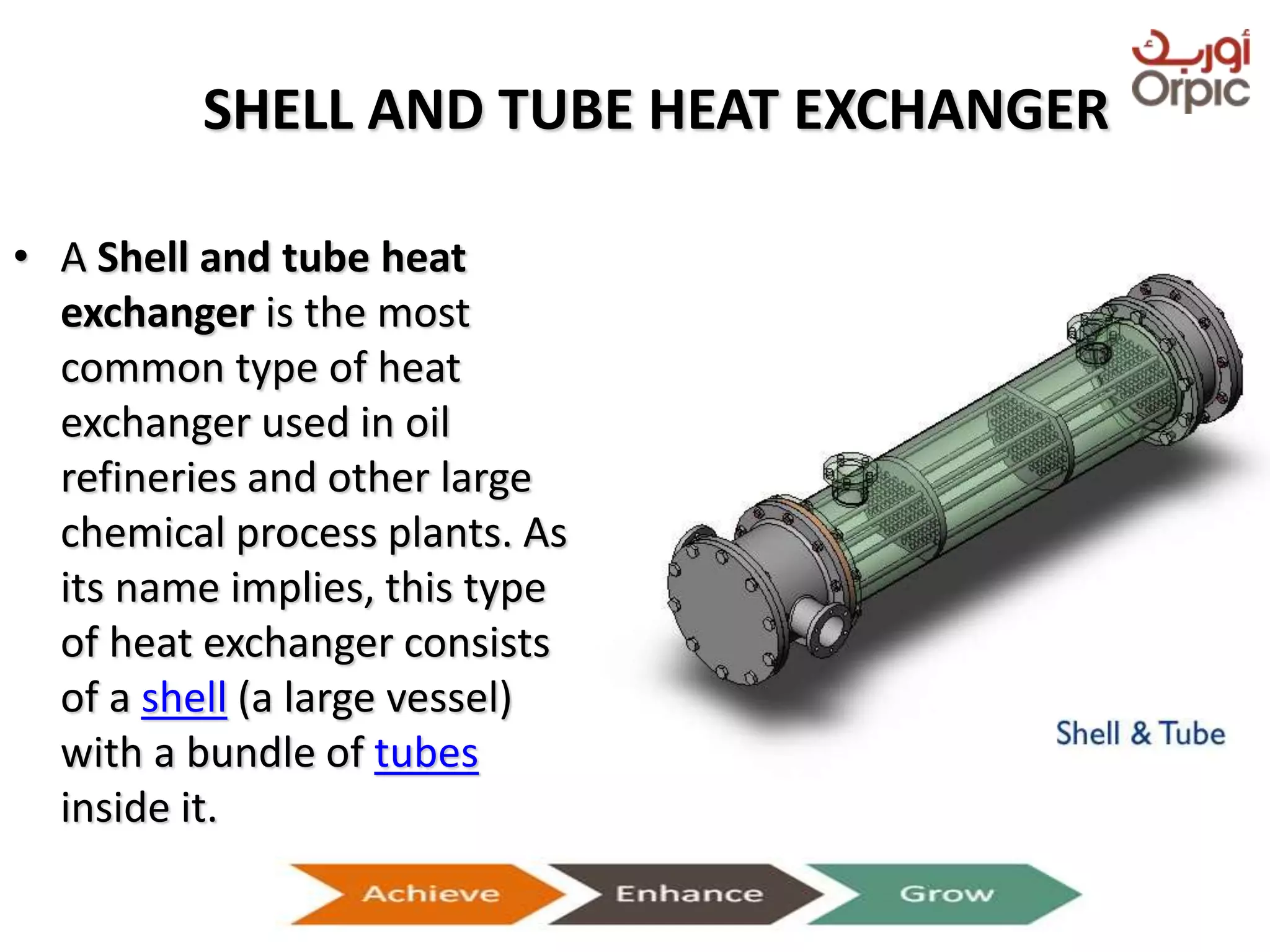

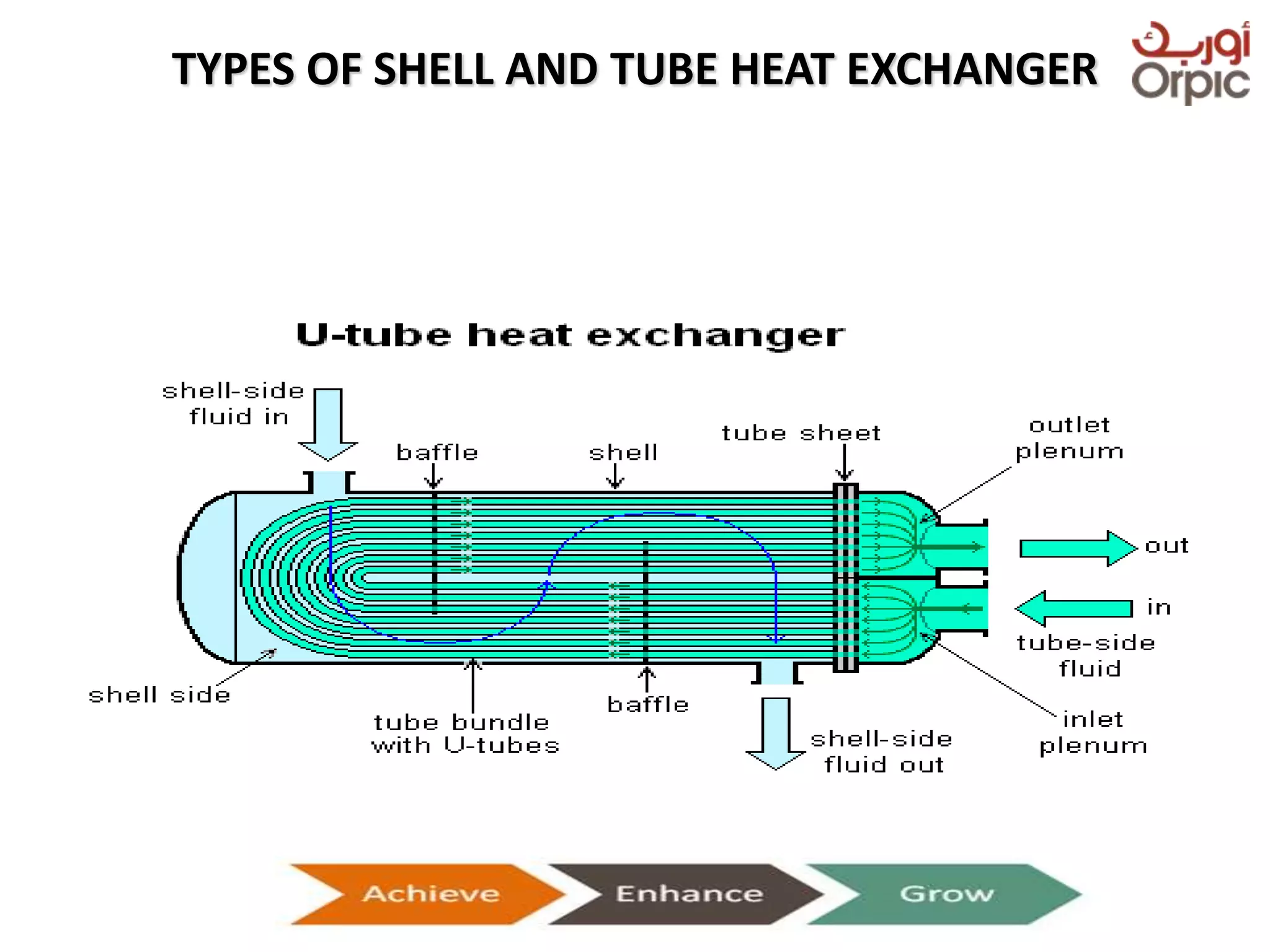

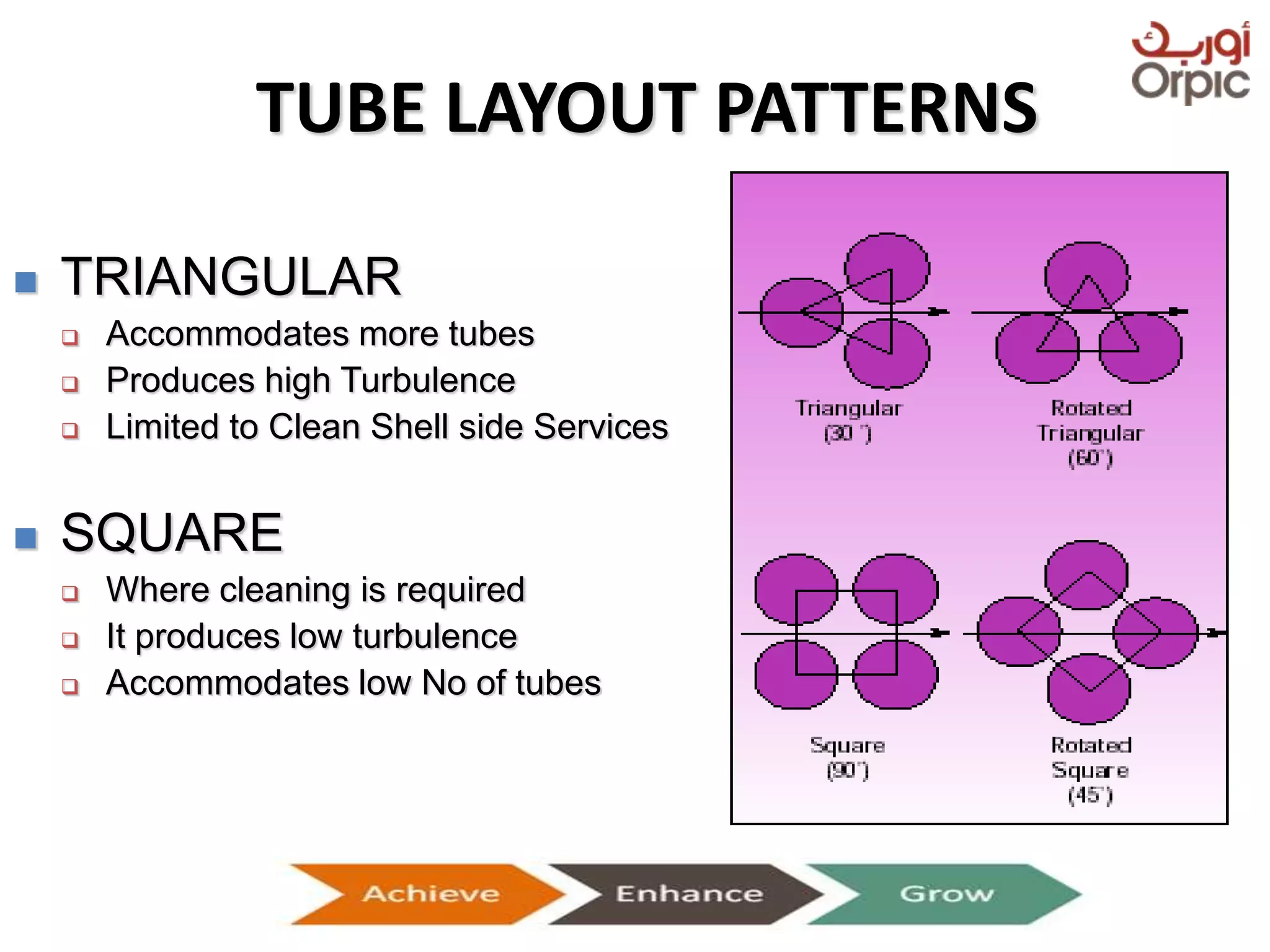

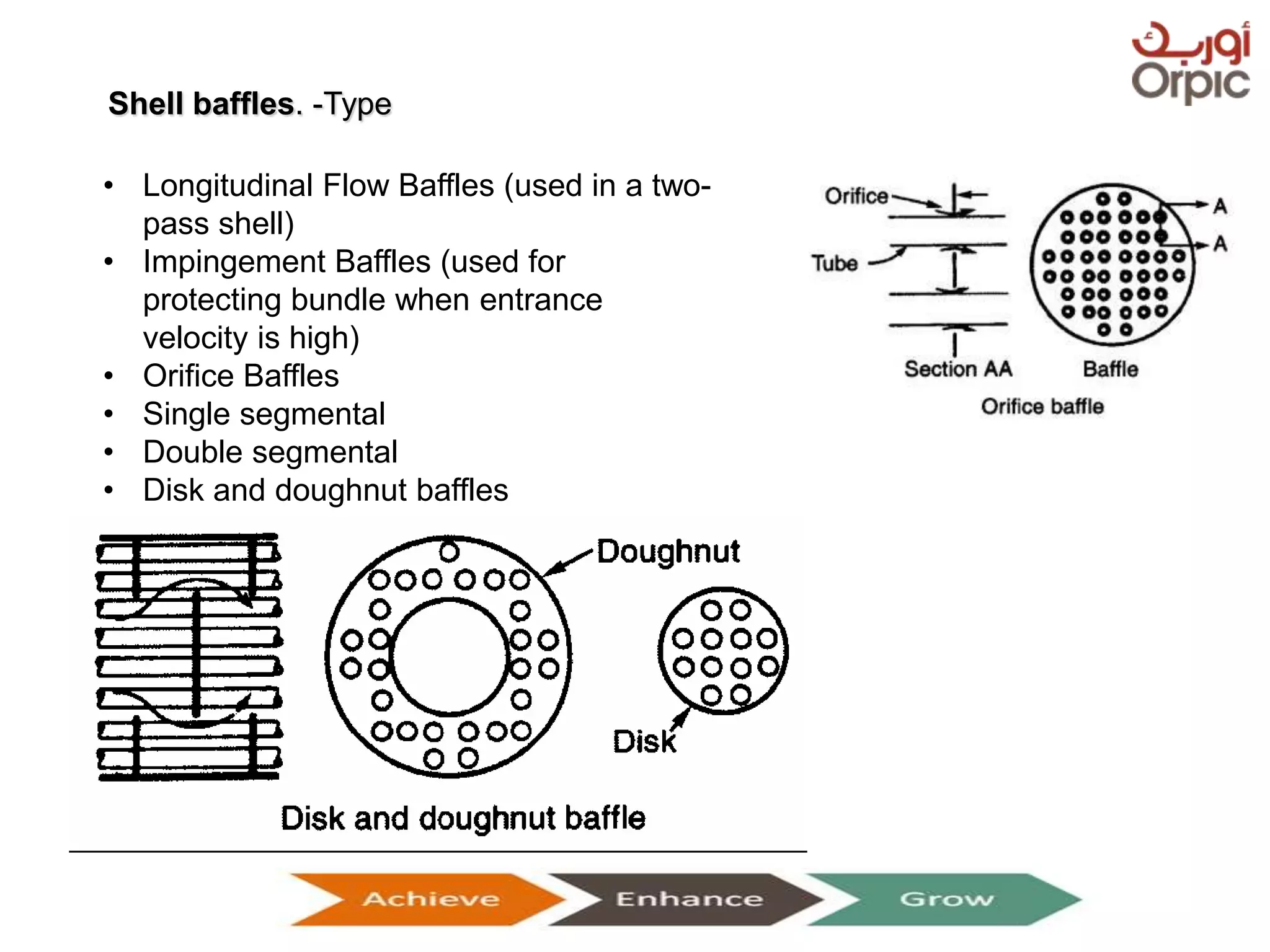

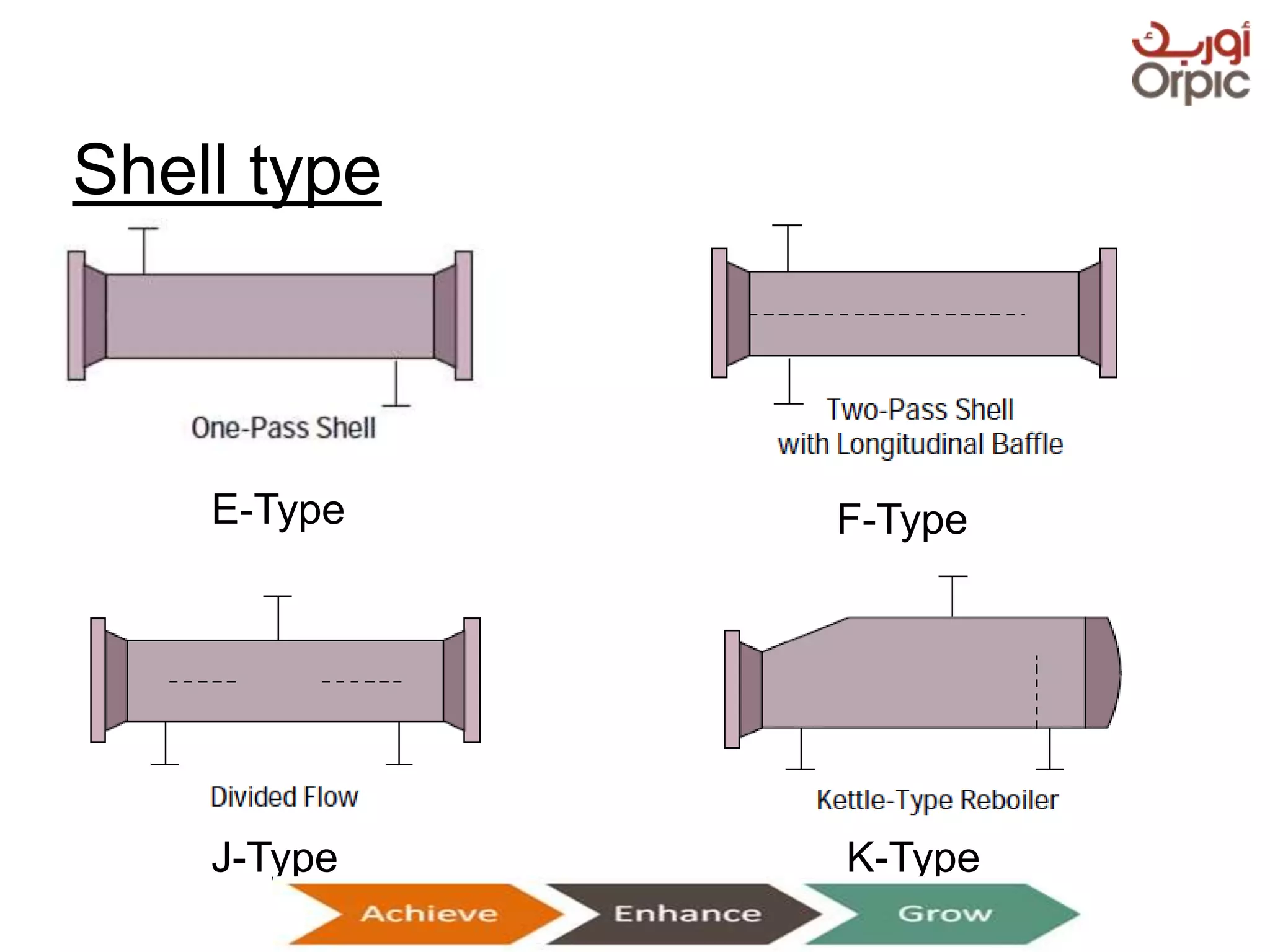

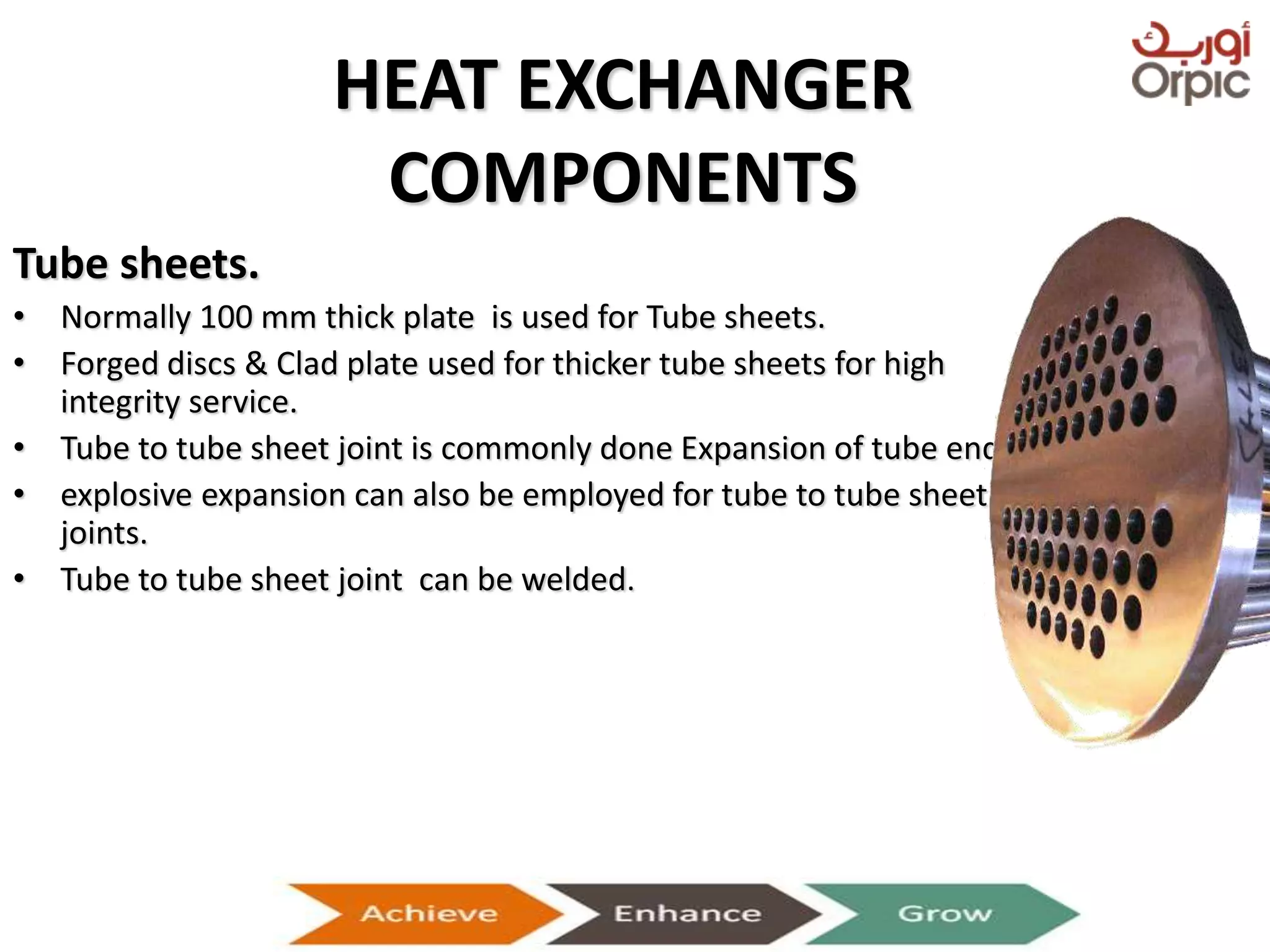

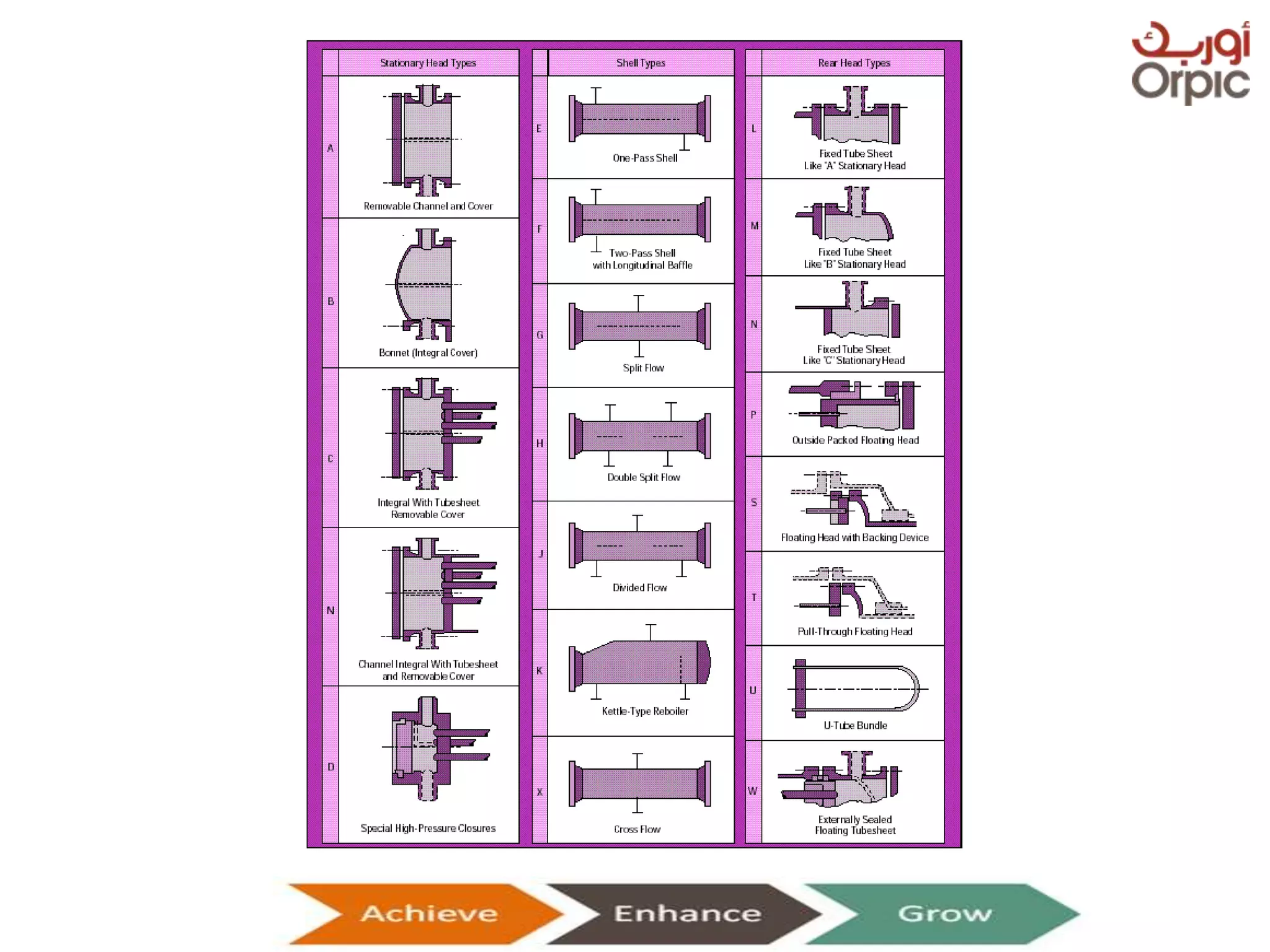

Heat exchangers are devices that transfer thermal energy between two or more fluids at different temperatures. The document discusses several types of heat exchangers including shell and tube, plate, air cooled, and spiral. It covers their basic designs, components, functions, applications, maintenance requirements, and classifications such as counterflow or parallel flow configurations. Selection of heat exchangers depends on factors like temperature ranges, pressure limits, flow capacities, and materials required.