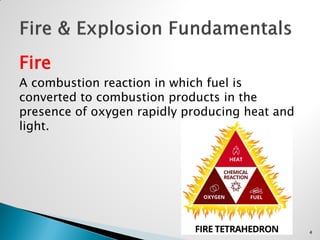

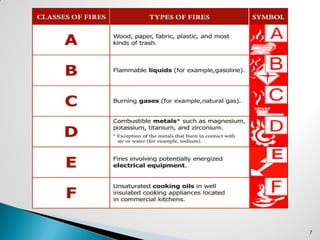

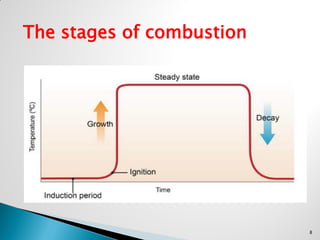

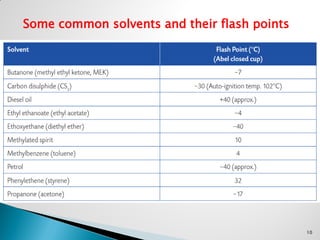

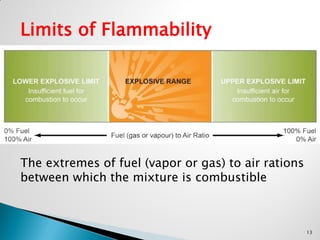

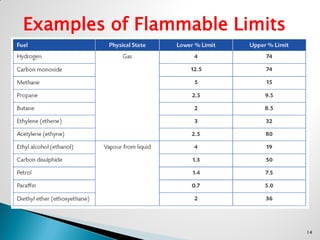

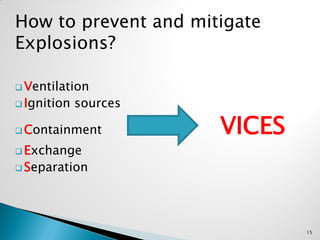

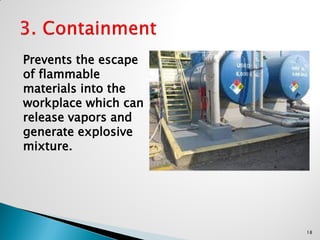

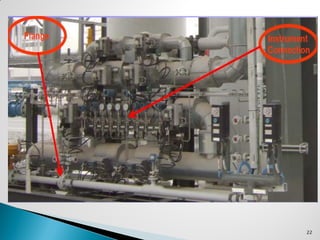

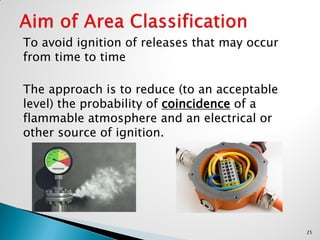

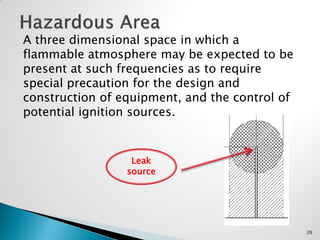

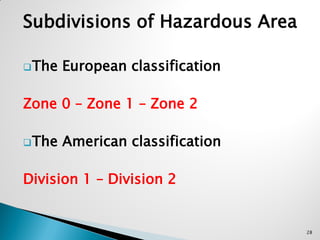

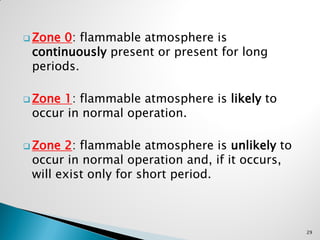

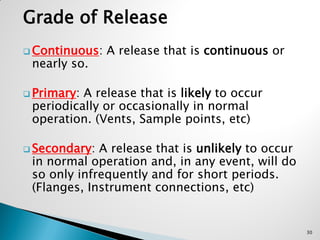

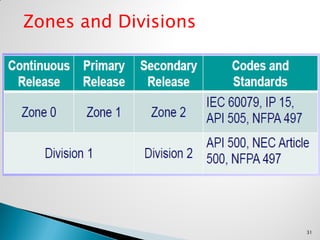

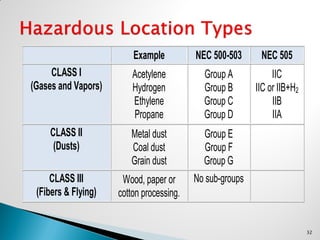

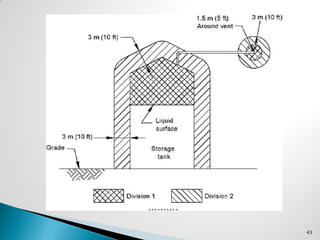

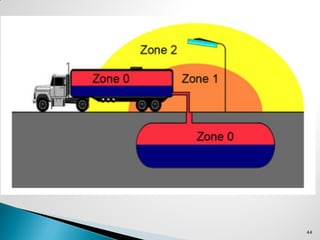

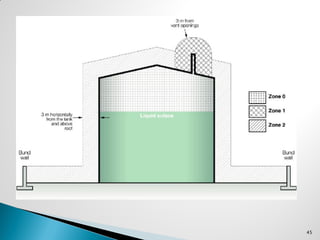

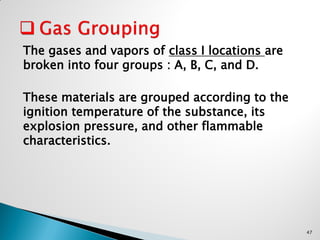

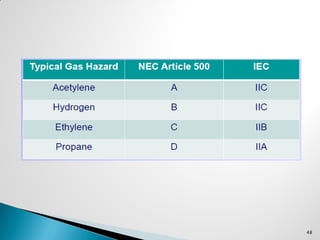

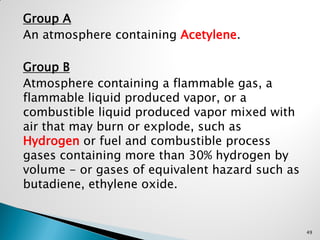

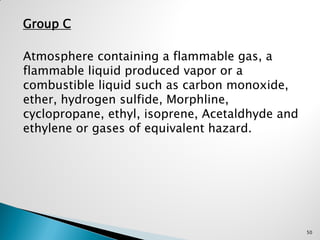

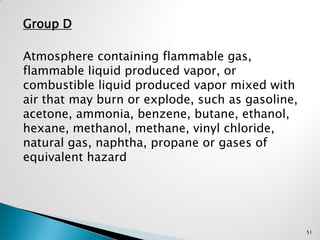

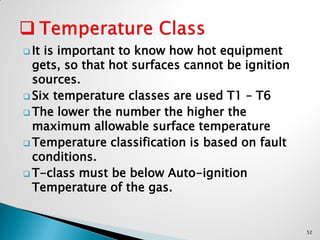

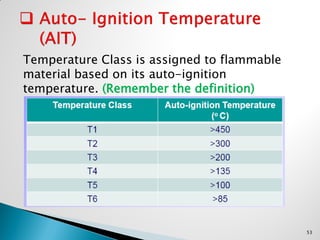

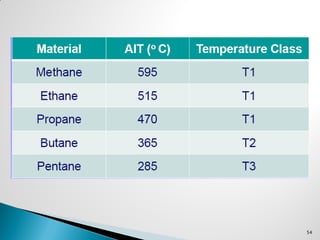

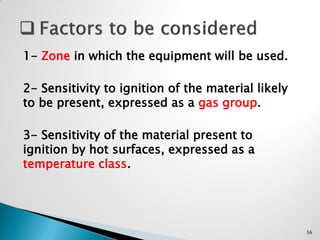

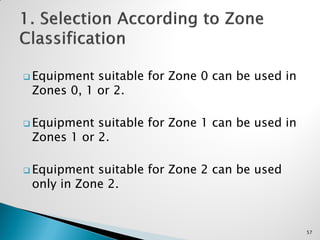

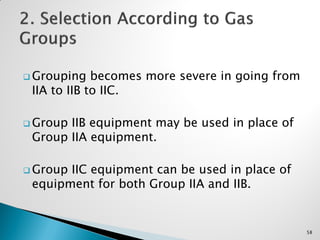

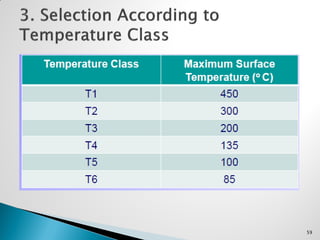

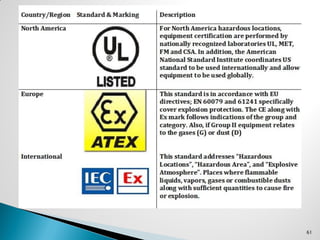

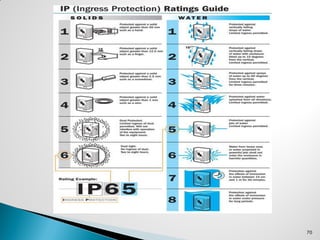

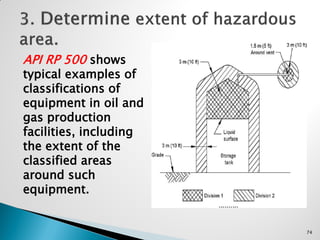

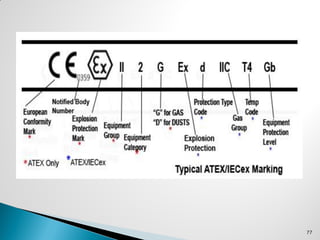

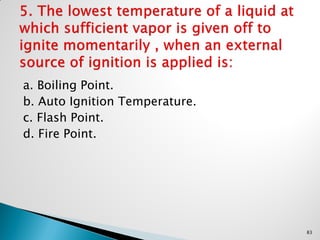

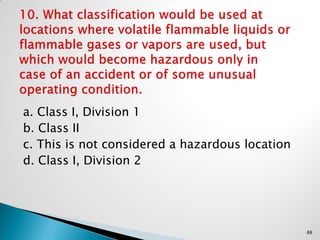

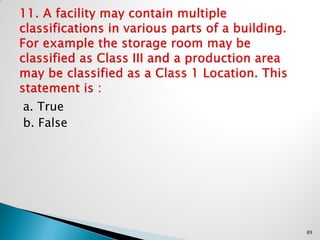

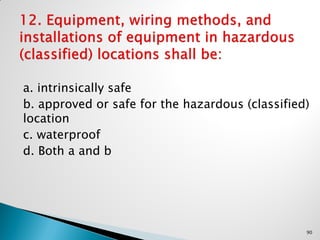

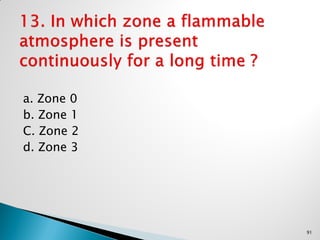

This document provides definitions and information related to fire and explosion hazards. It defines key terms like hazard, risk, fire, explosion, ignition sources, and stages of combustion. It also discusses flash point, fire point, auto-ignition temperature, and flammability limits. The document outlines how to prevent and mitigate explosions through ventilation, ignition source control, containment, material substitution, and separation. It also discusses hazardous area classification and electrical equipment certification for different zones and gas/vapor groups.