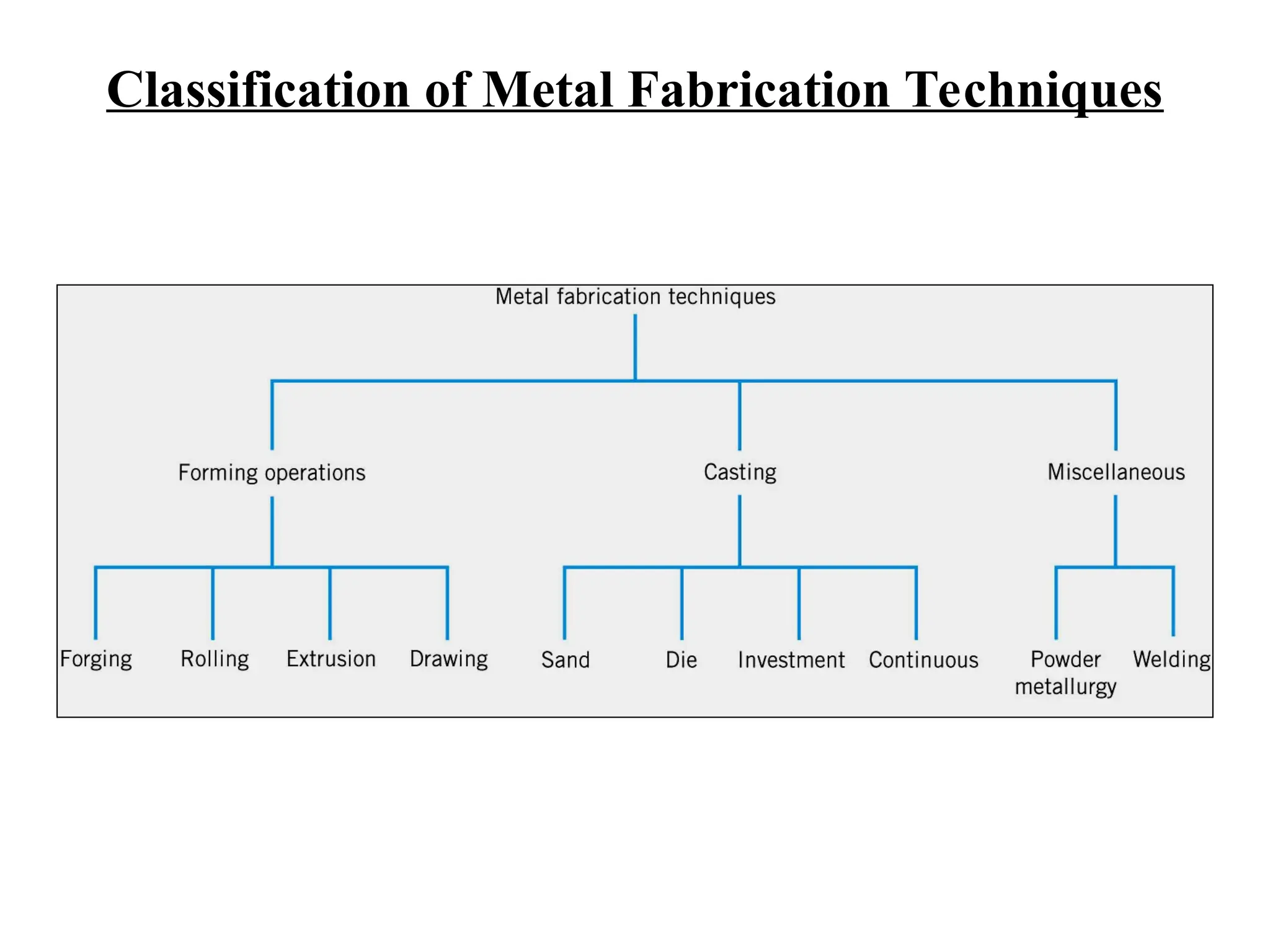

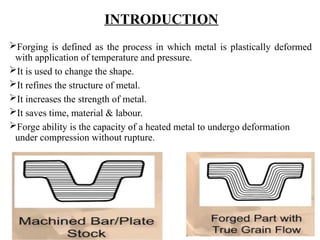

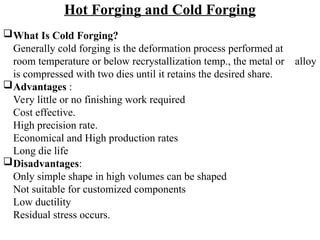

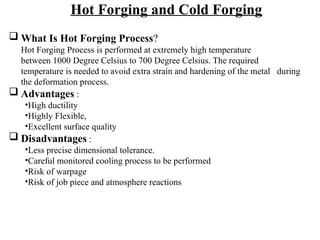

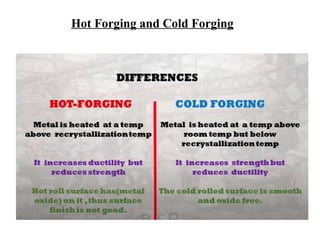

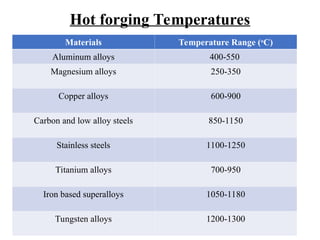

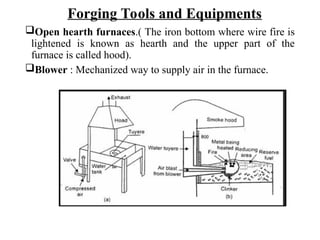

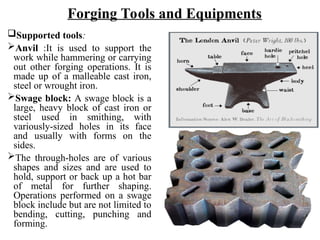

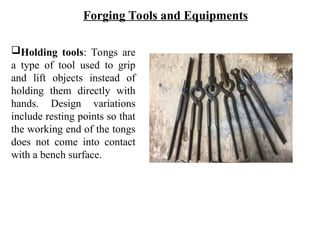

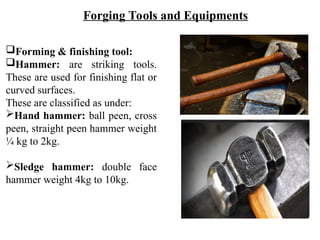

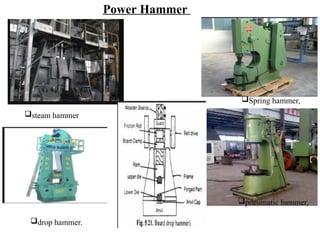

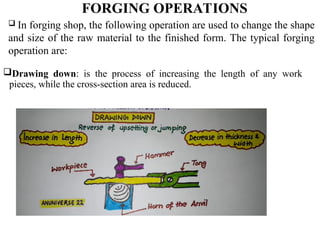

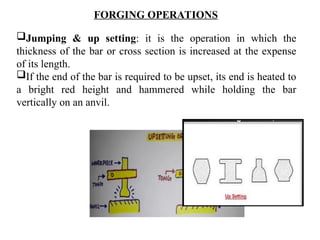

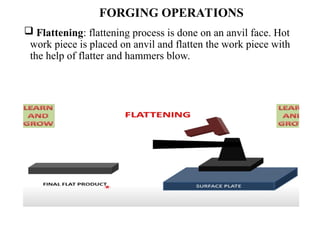

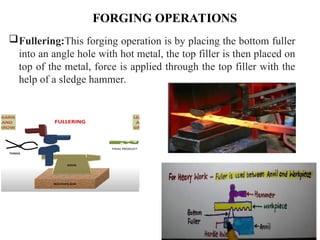

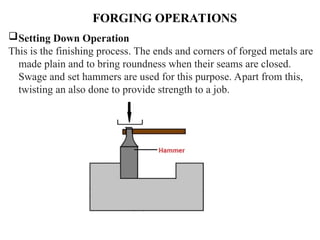

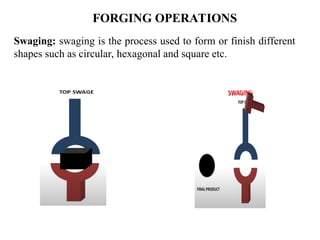

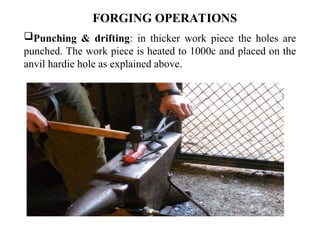

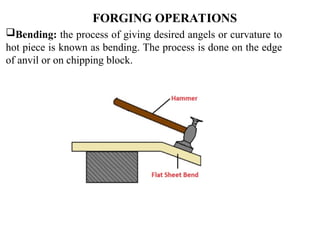

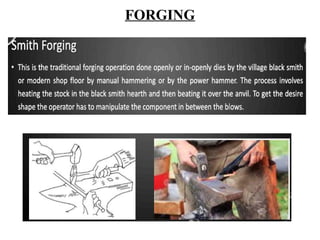

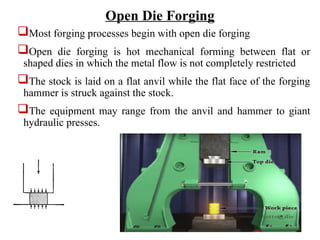

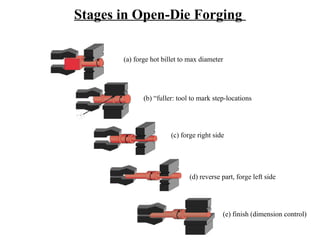

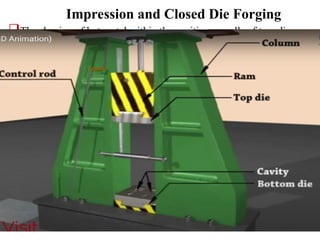

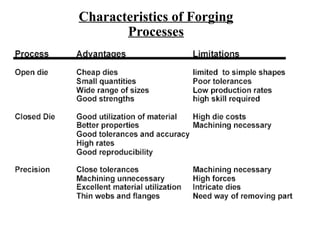

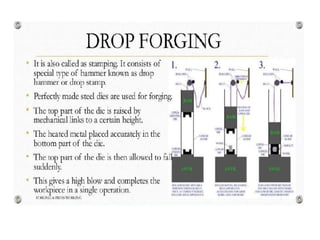

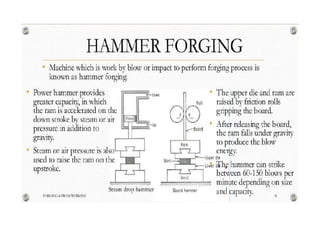

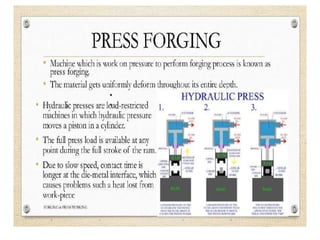

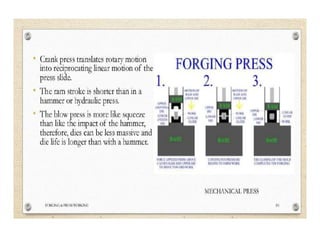

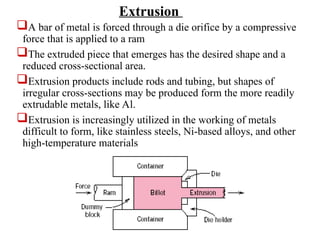

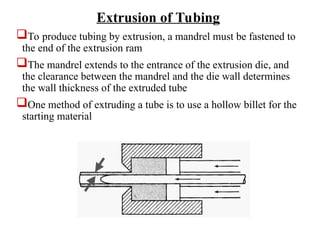

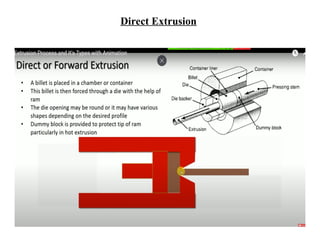

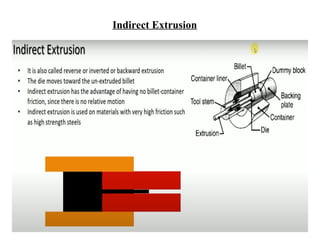

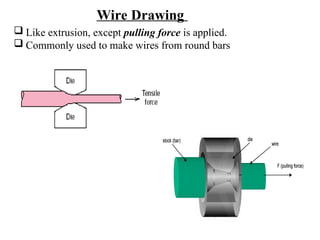

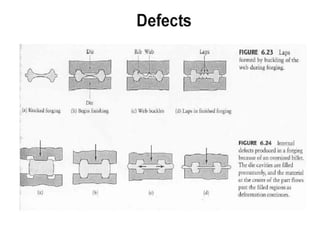

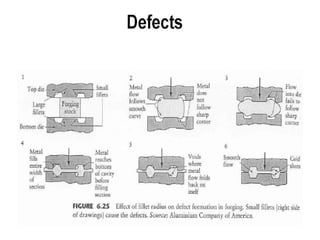

The document provides an overview of metal fabrication techniques, particularly focusing on forging processes such as hot and cold forging, detailing their advantages and disadvantages. It describes various forging tools and operations, emphasizing techniques like drawing down, swaging, and punching, and highlights the principles of open-die and closed-die forging processes. The document also touches on extrusion and wire drawing methods used to produce different metal shapes and products.