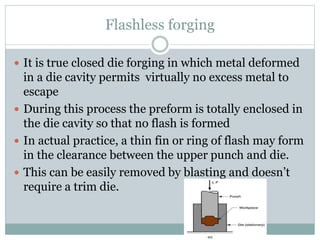

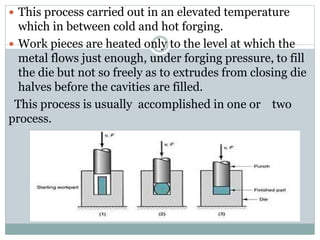

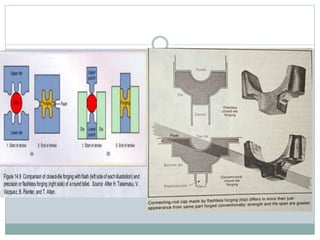

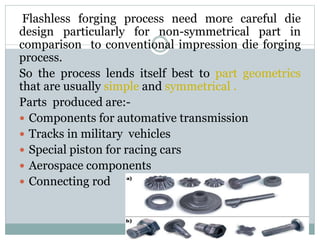

This document discusses flashless forging, a near net shape forging process where metal is compressed in a die cavity without any excess flash. Flashless forging provides benefits over closed die forging such as material and energy savings from eliminating flash, higher production rates due to no trimming, and better part dimensions and grain structure. While it enables net shape parts and savings, flashless forging also requires more complex dies and strict control over blank weight and temperature compared to conventional forging.