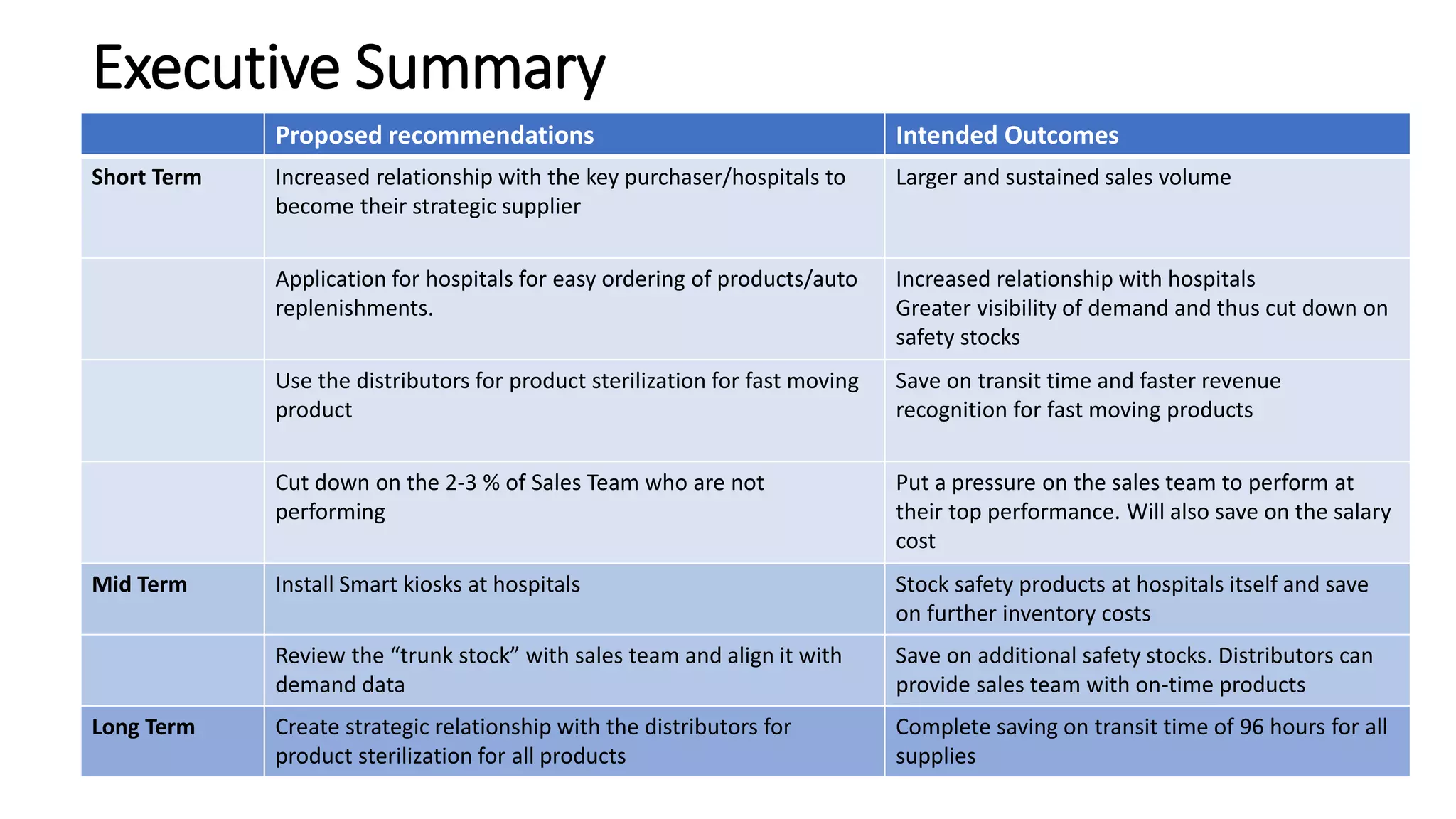

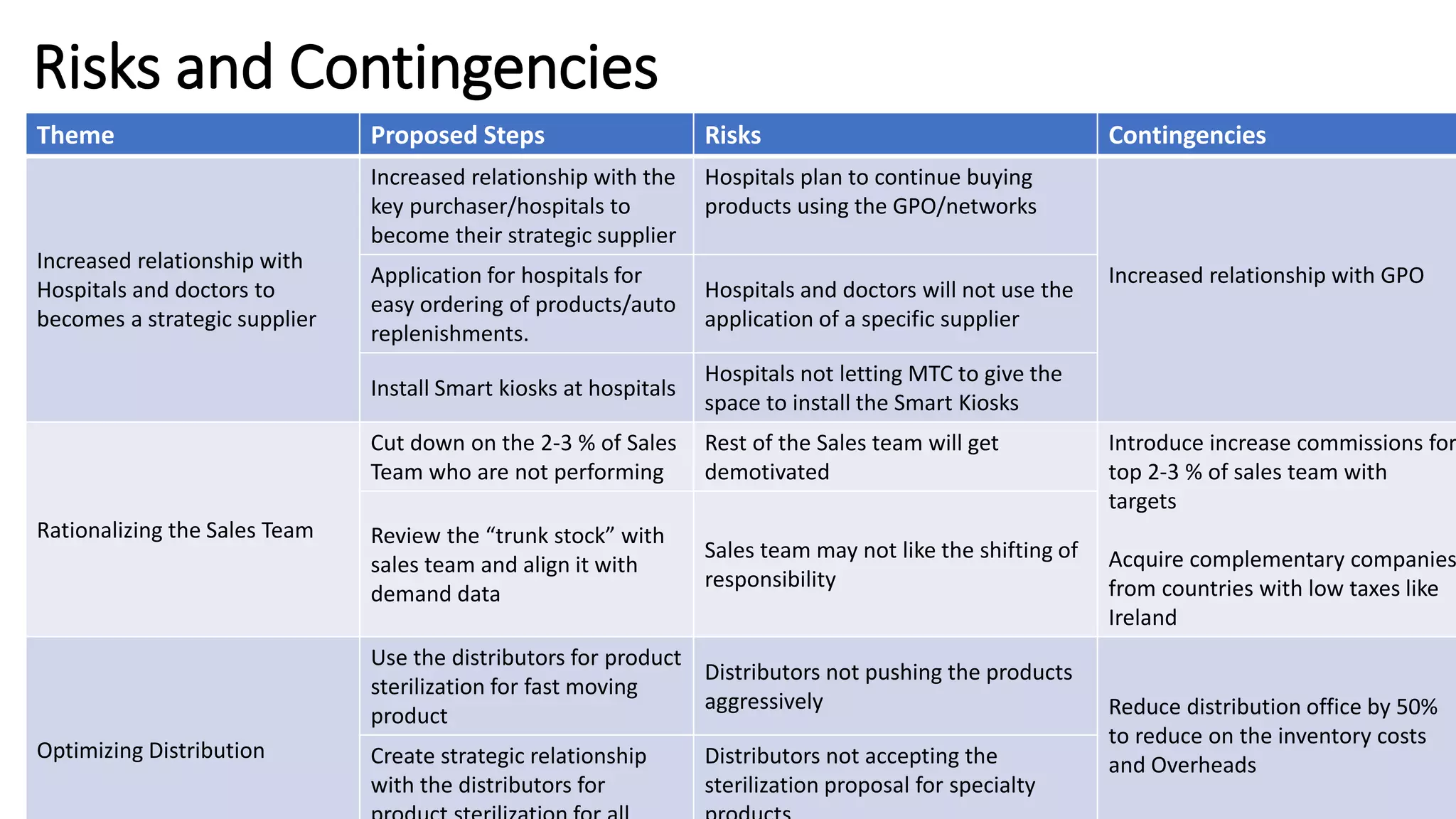

MTC is a medical equipment supplier facing a 2.3% tax impacting 10% of profits. To offset this, MTC aims to improve its supply chain strategy. Short term plans include increasing relationships with key hospital customers to become their strategic supplier. Mid term plans involve installing smart kiosks at hospitals to reduce inventory costs. Long term plans center around creating strategic relationships with distributors for product sterilization to save on transit time. The strategy aims to cut costs and negate the new tax.