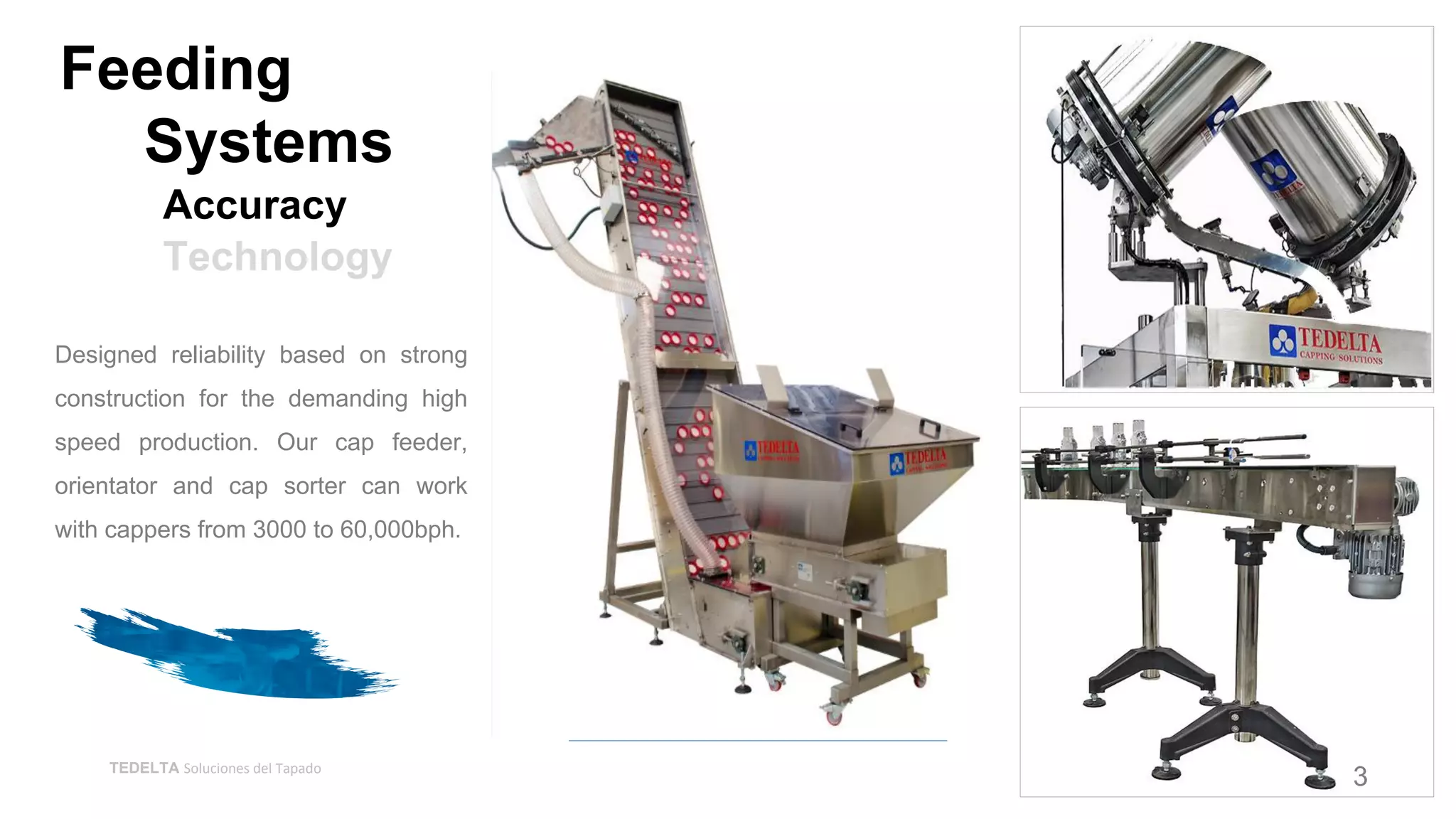

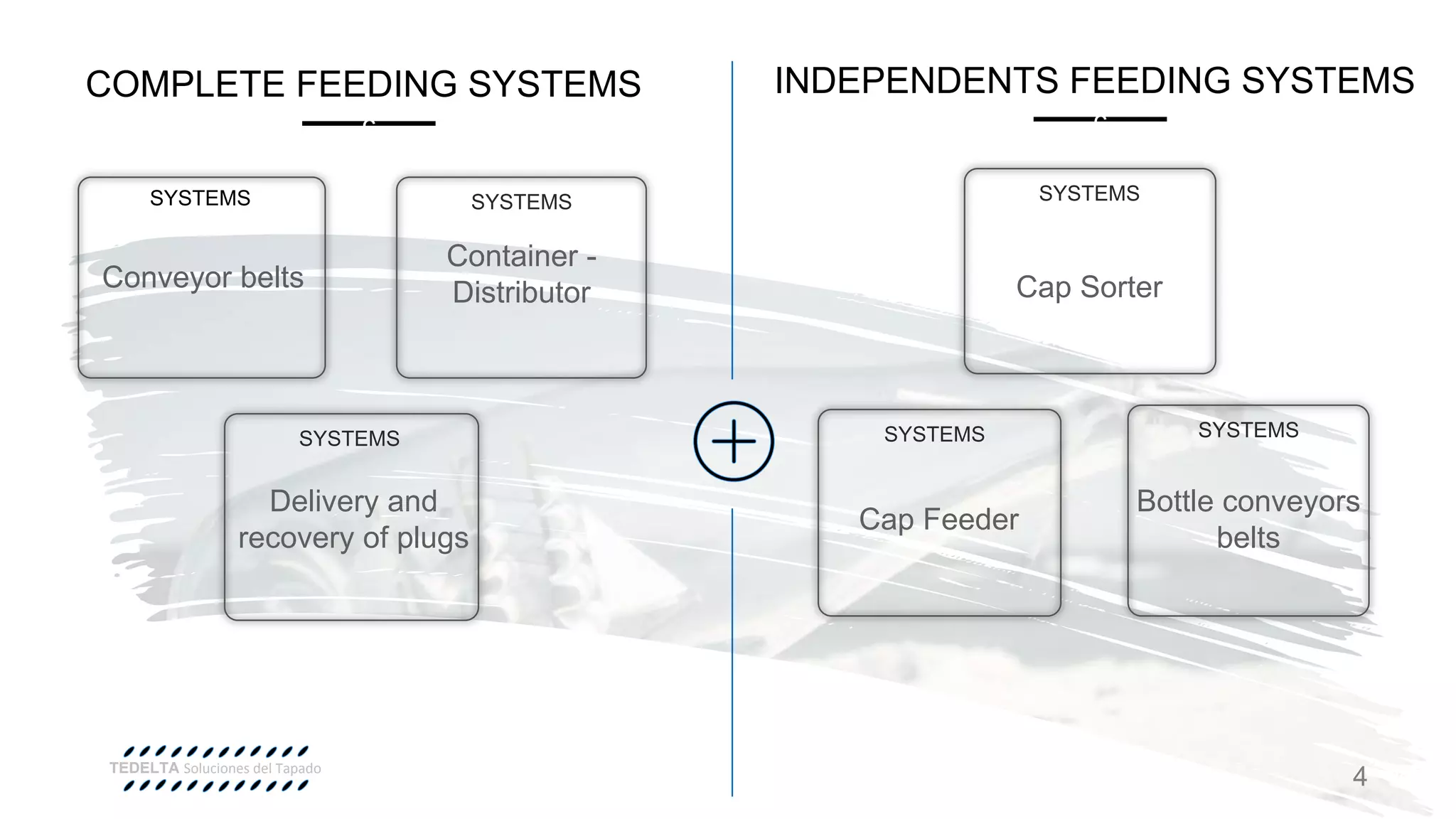

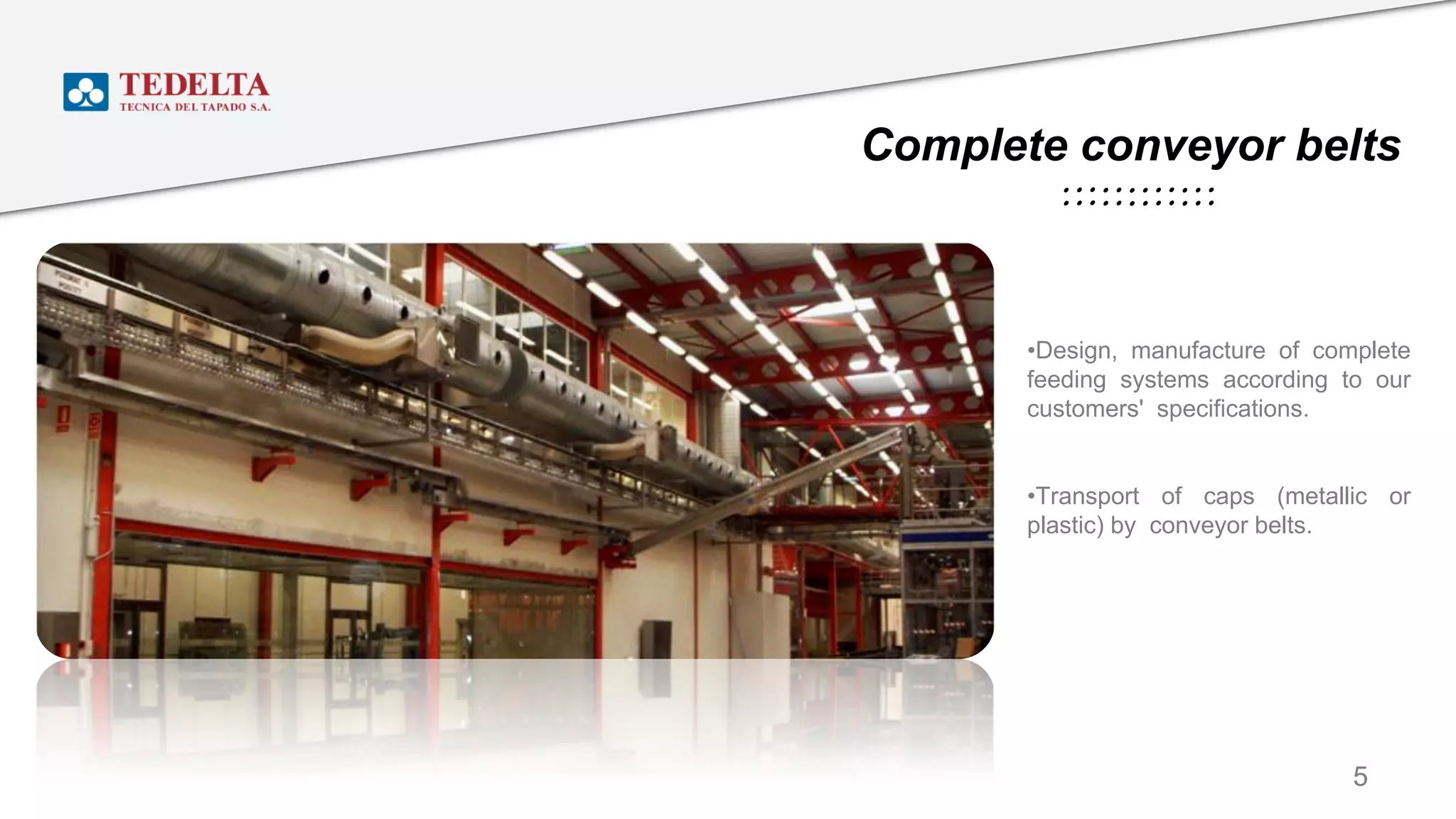

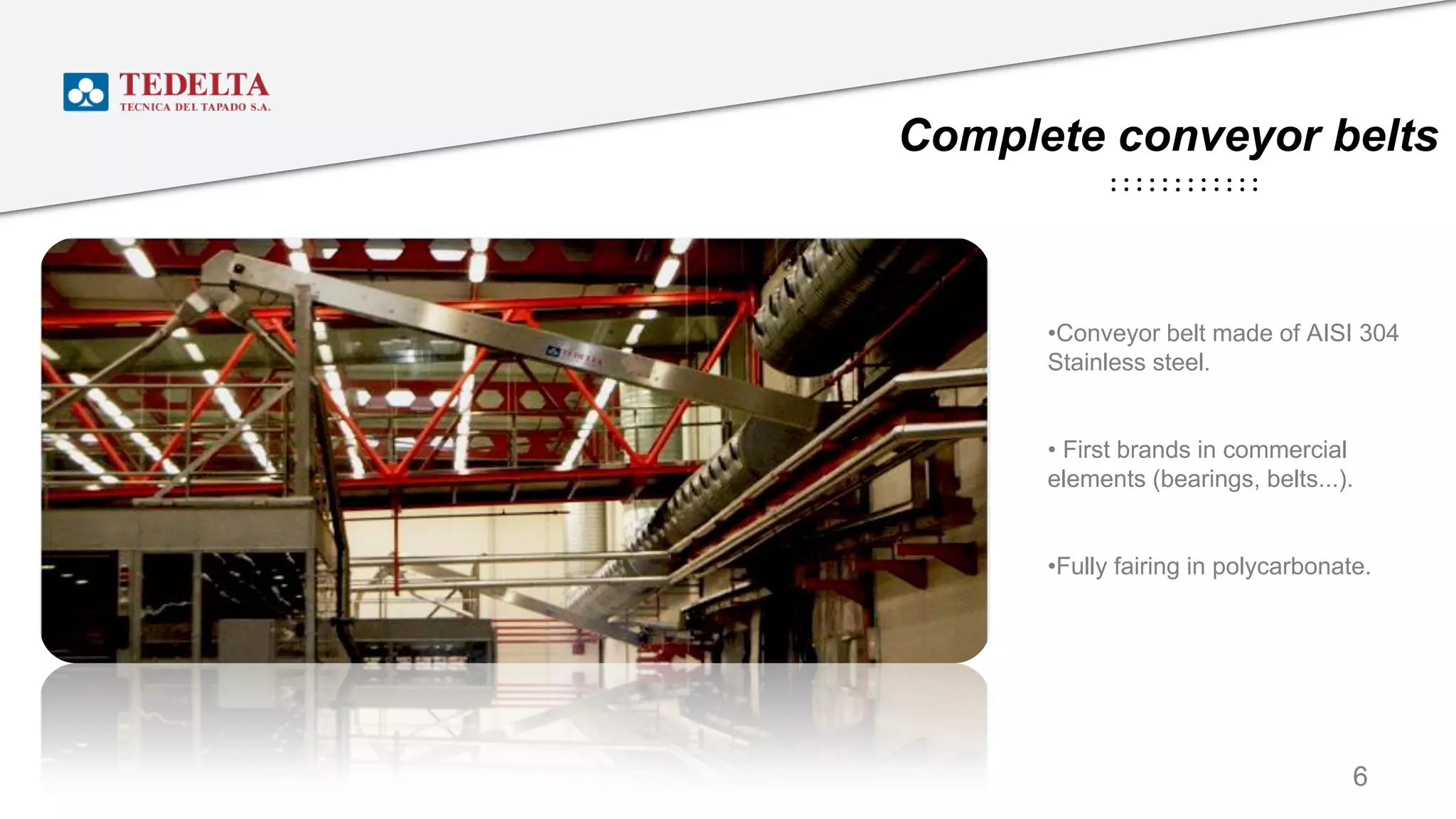

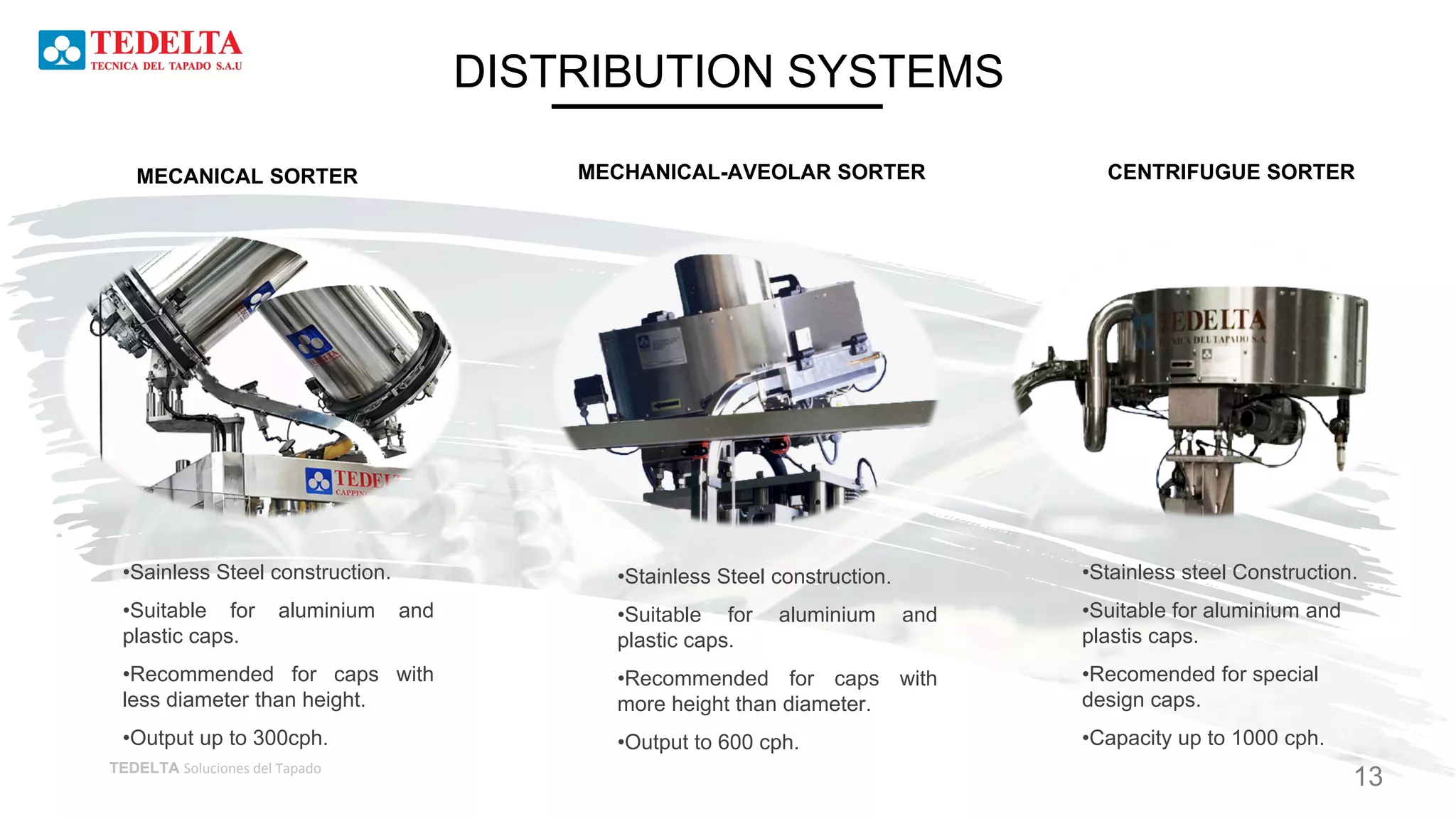

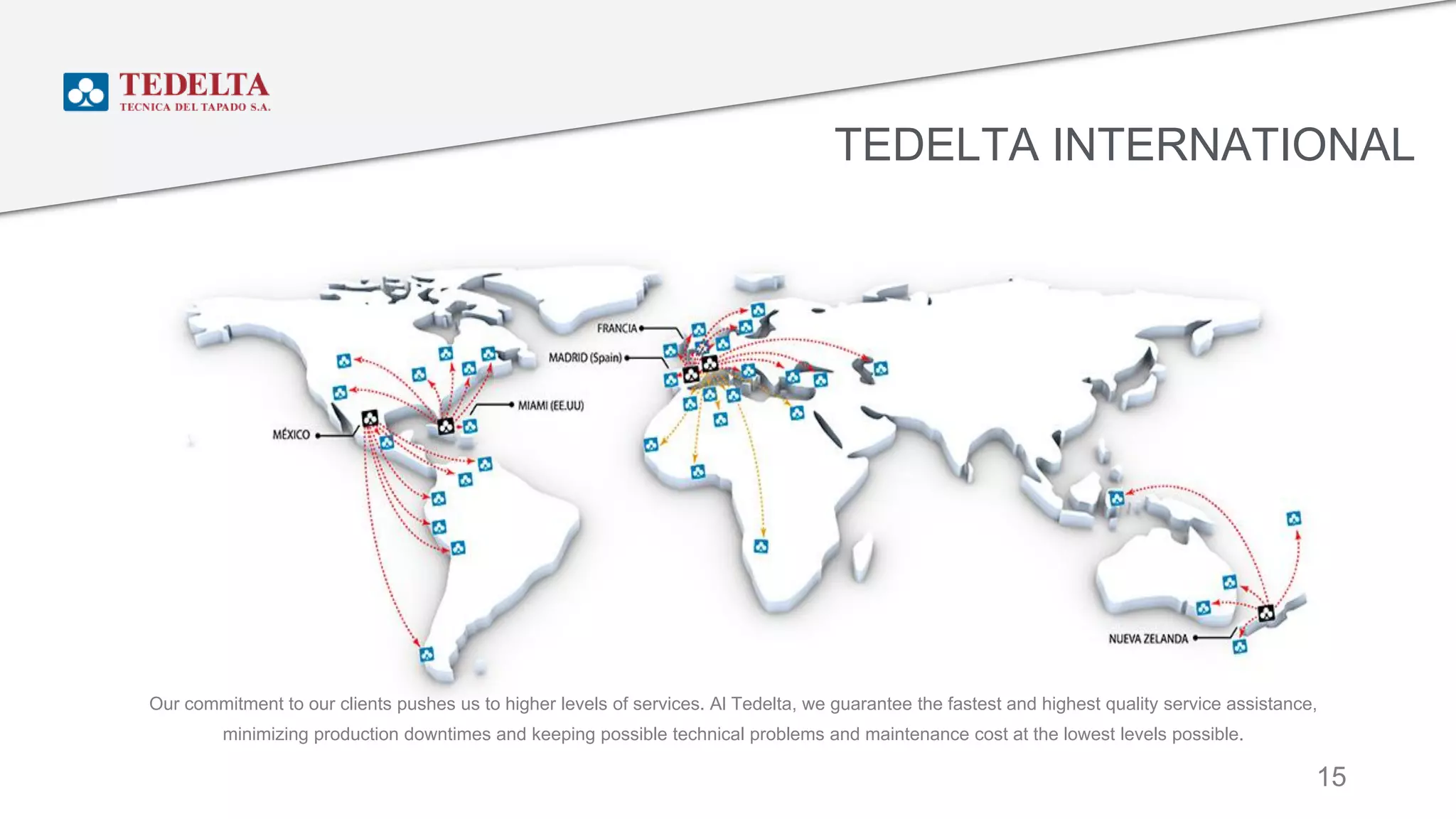

Tedelta Soluciones del Tapado specializes in capping technology, providing efficient cap feeding systems and custom solutions for manufacturers and end customers. With over 40 years of experience, Tedelta is a leading Spanish manufacturer of capping machines and related systems, ensuring reliable and high-speed production. Their comprehensive offerings include various cap feeders, conveyor belt systems, and pneumatic systems, all designed to meet specific customer needs.