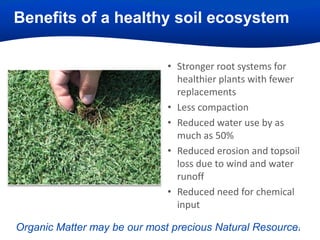

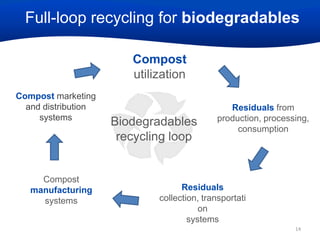

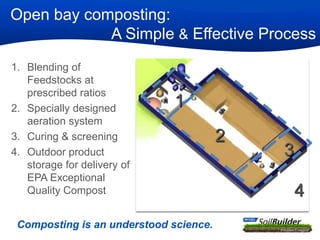

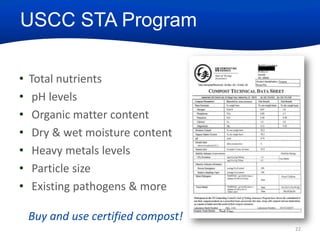

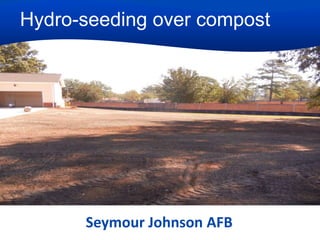

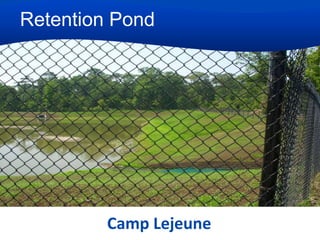

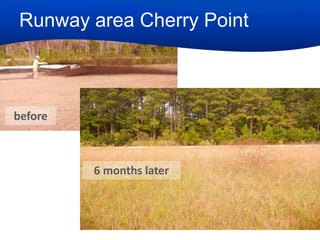

Ruth King from McGill Premium Composts presented at the 2013 FEDCON Summit hosted by the North Carolina Military Business Center and Senator Richard Burr on October 16-17, 2013. The presentation discussed how compost can help the US military meet sustainability goals by offering green purchasing solutions, reducing waste, and improving soils. Premium compost was shown to benefit landscaping, erosion control, and athletic fields by building healthy soil and reducing needs for chemicals, water, and plant replacements. McGill processes compost at several facilities across the US from local food, yard, and biosolid waste in a controlled system to produce consistent, high-quality compost certified by the US Composting Council.