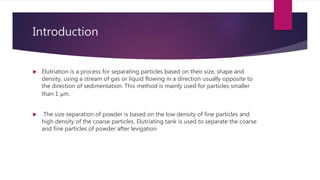

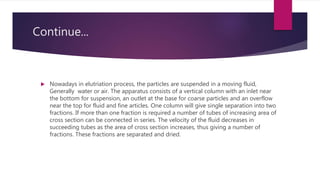

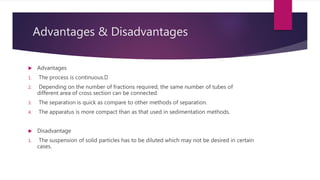

The elutriation method separates particles based on size, shape, and density using a stream of gas or liquid flowing in the opposite direction of sedimentation. Fine particles remain suspended due to their low density, while coarse particles settle due to their high density. The process involves mixing a powder sample with water in an elutriation tank, allowing particles to settle or remain suspended based on density, and collecting fractions from outlets at different heights as the sample is withdrawn. Modern elutriation uses a column with inlets, outlets, and overflows to separate particles into fractions based on the decreasing fluid velocity in connected columns of increasing cross-sectional area. The method provides a continuous, quick separation into multiple fractions using compact apparatus