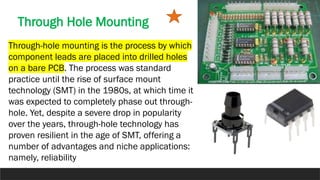

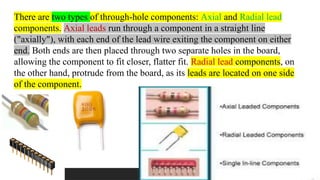

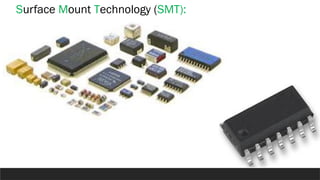

This chapter discusses the two primary methods for mounting components on printed circuit boards (PCBs): through-hole mounting and surface mount technology (SMT). Through-hole mounting offers advantages such as stronger mechanical bonds and reliability for high-stress applications, while SMT has become the predominant method due to its cost-effectiveness and efficiency. Key differences include SMT requiring no drilling of holes and accommodating smaller components on both sides of the board.