This document summarizes various aspects of food drying, including:

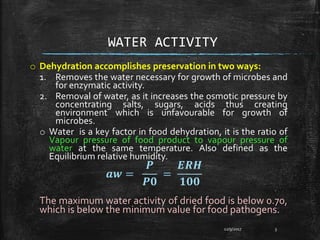

- Drying removes water from foods to extend shelf life without refrigeration by inhibiting microbial growth and enzymatic activity.

- Key factors that influence drying rate are temperature, humidity, air velocity, and drying time. Common drying methods include hot air drying, freeze drying, and sun drying.

- Important dryer types are kiln dryers, tunnel dryers, fluidized bed dryers, and spray dryers. Proper dryer selection depends on production needs and food properties.