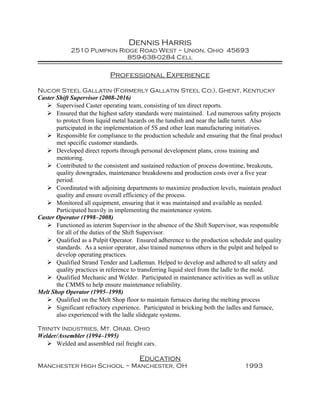

Dennis Harris has over 20 years of experience in steel production, including roles as Caster Shift Supervisor and Caster Operator at Nucor Steel Gallatin. As Shift Supervisor, he supervised a team of 10 employees, ensured safety standards, met production schedules and quality standards, developed employees, and implemented process improvements. Previously as Caster Operator, he qualified in multiple roles including Pulpit Operator, Strand Tender, Ladleman, Mechanic, and Welder. He also has experience in melt shop operations and welding/assembly. Harris has a high school diploma and completed additional continuous casting training in 2009.