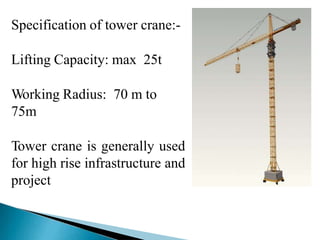

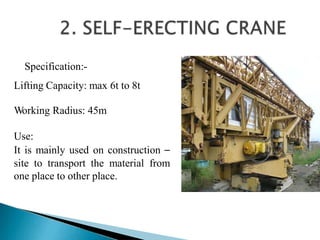

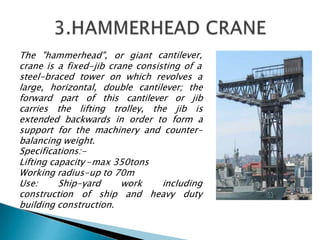

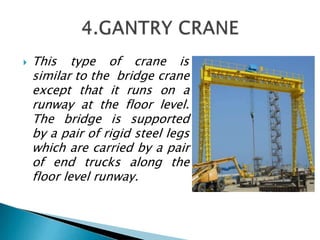

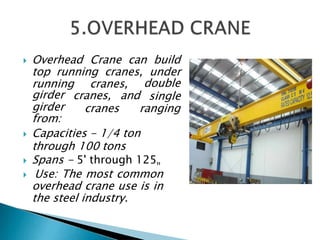

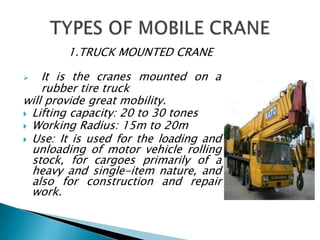

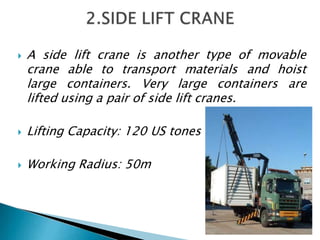

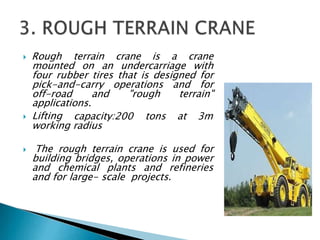

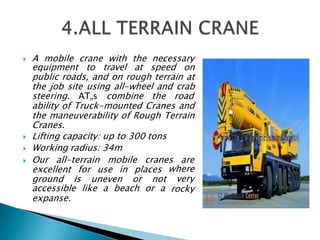

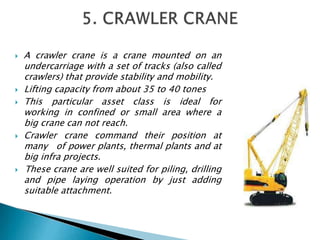

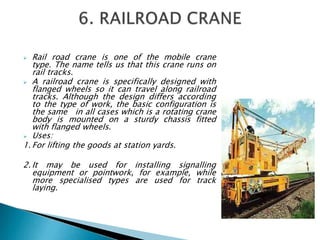

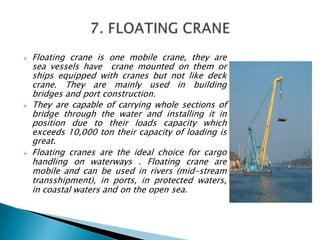

This document discusses different types of cranes and their uses in civil engineering. It describes fixed cranes like tower cranes, hammerhead cranes, and bridge cranes. It also describes mobile cranes like truck mounted cranes, rough terrain cranes, all-terrain cranes, crawler cranes, railroad cranes, floating cranes, and aerial cranes. Each crane type is defined along with its typical lifting capacity, working radius, and common construction uses. The document also covers crane safety and potential causes of crane failure.