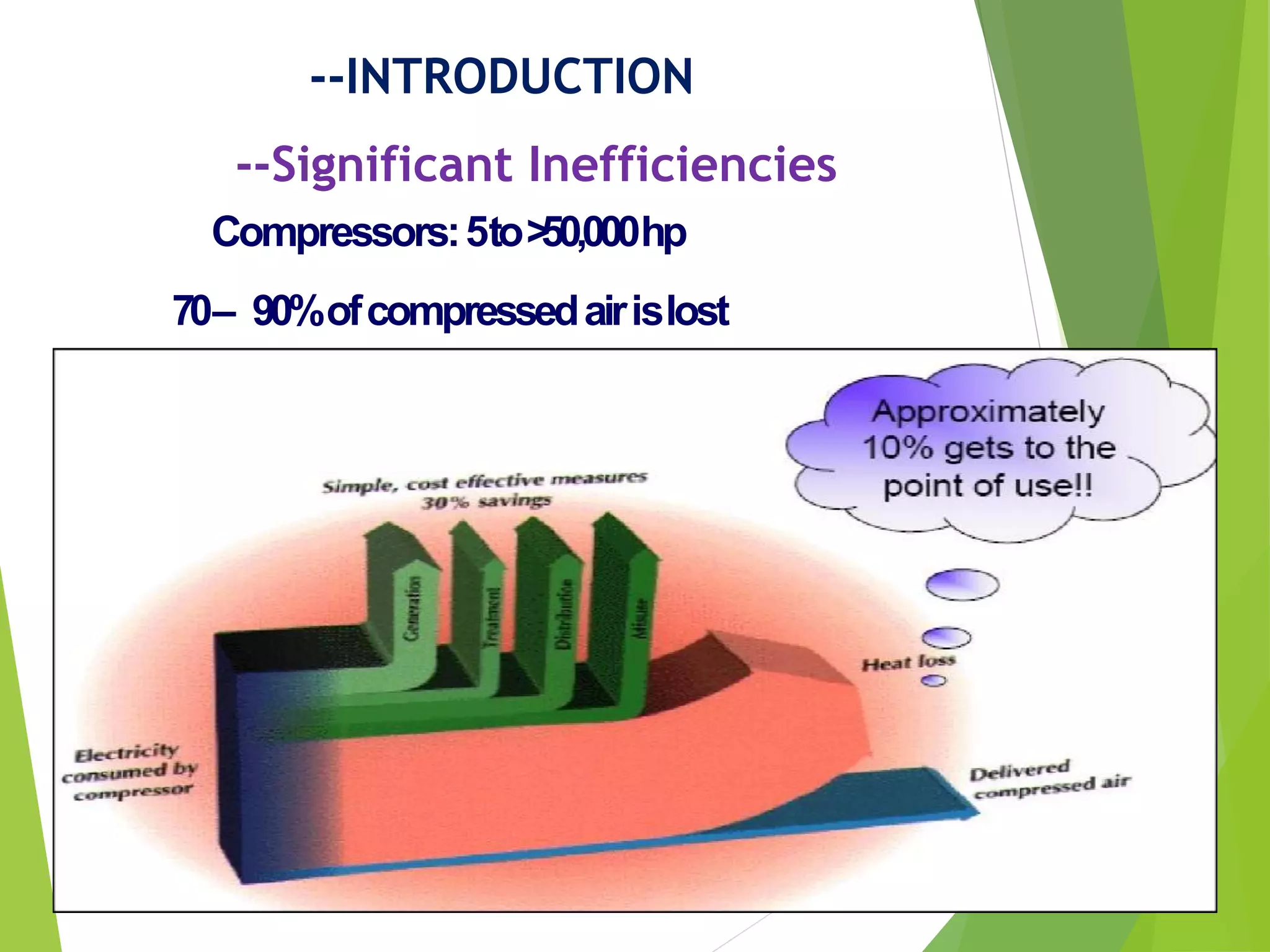

This document provides an overview of compressed air systems and opportunities for improving energy efficiency. It discusses types of compressors, how to assess compressor performance and leaks, and identifies several areas where energy efficiency can be improved, including installing intercoolers and aftercoolers, minimizing pressure drops and leakage, optimizing pressure settings, improved condensate removal, and implementing control strategies and maintenance practices. The overall message is that significant electricity savings of 20-50% are possible from a well-managed compressed air system with reduced pressure drops, leaks, and operating pressures.

![-Assesment of Compressors

-Leak Qualification Method

-Total Leakage Calculation

--Leakage (%) = [(Tx100)/(T +

t)]

--T=On load time(minutes)

t=off load time (Minutes)

--well maintained system: less than 10%

leakages](https://image.slidesharecdn.com/compressedairsupply-210512102207/75/Compressed-air-supply-19-2048.jpg)