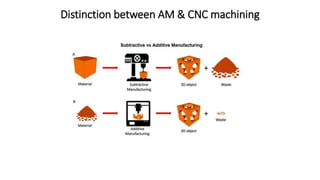

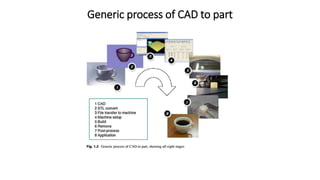

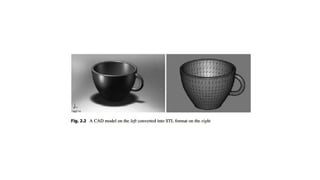

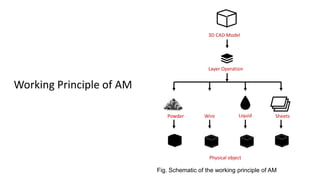

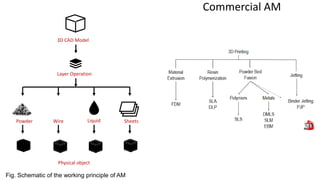

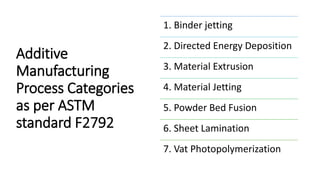

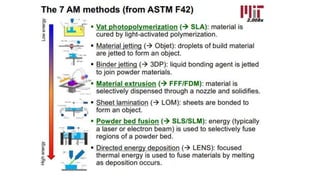

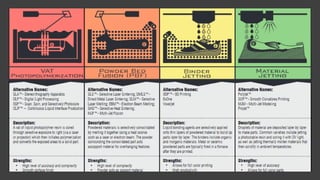

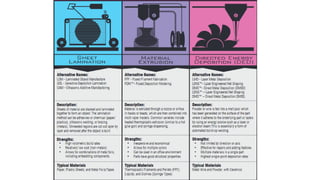

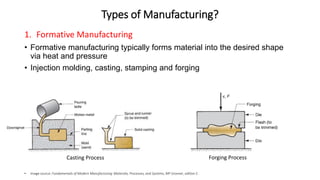

The document discusses additive manufacturing (AM) which involves building up a part layer by layer, unlike subtractive manufacturing which removes material. It describes three main types of manufacturing and focuses on AM. AM techniques build parts from 3D model data by joining materials together in successive layers, such as powder bed fusion which uses a laser. The document outlines advantages like reduced waste but also limitations including part size and material properties. It provides examples of common AM processes like fused deposition modeling and selective laser sintering.

![Types of Manufacturing?

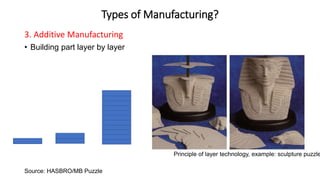

3. Additive Manufacturing (AM)

Building up the part layer by layer

• A process of joining materials to make objects from 3D model data, usually layer

upon layer, as opposed to subtractive manufacturing methodologies [1].

[1] ISO/ASTM 52900:2015 Standard Terminology for Additive Manufacturing Technologies

CAD File Slicing 3D Printing Final physical object](https://image.slidesharecdn.com/cnctechnology-230531093500-5e823c80/85/CNC-Technology-pptx-7-320.jpg)