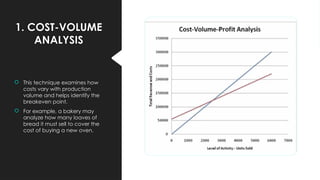

Capacity planning is a crucial aspect of operations management that ensures organizations have the necessary resources to meet demand efficiently, impacting cost efficiency, resource allocation, and customer satisfaction. The process involves determining the type and amount of capacity needed and the timing for capacity expansion, with considerations for cost, control, flexibility, and core competency. Effective capacity planning allows businesses to optimize operations, adapt to market demands, and maintain efficiency.