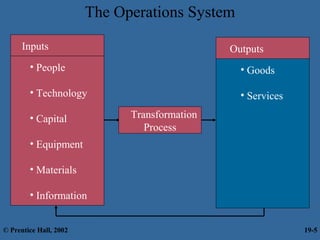

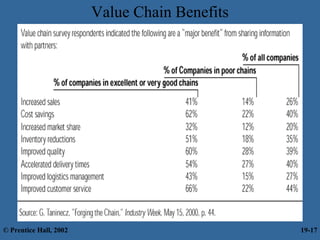

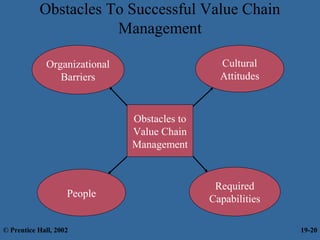

The document discusses operations management and value chain management. It describes operations management as the process of transforming inputs like labor and materials into goods and services. Value chain management aims to create the highest value for customers by managing activities along the entire transformation process. The key requirements for successful value chain management include coordination and collaboration between partners, investments in technology, organizational processes that add value, and a culture of sharing and flexibility.